Electric machine, in particular separately excited synchronous machine

A synchronous motor, contact element technology, applied in circuits, current collectors, electromechanical devices, etc., can solve problems such as strengthening and insufficient axial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

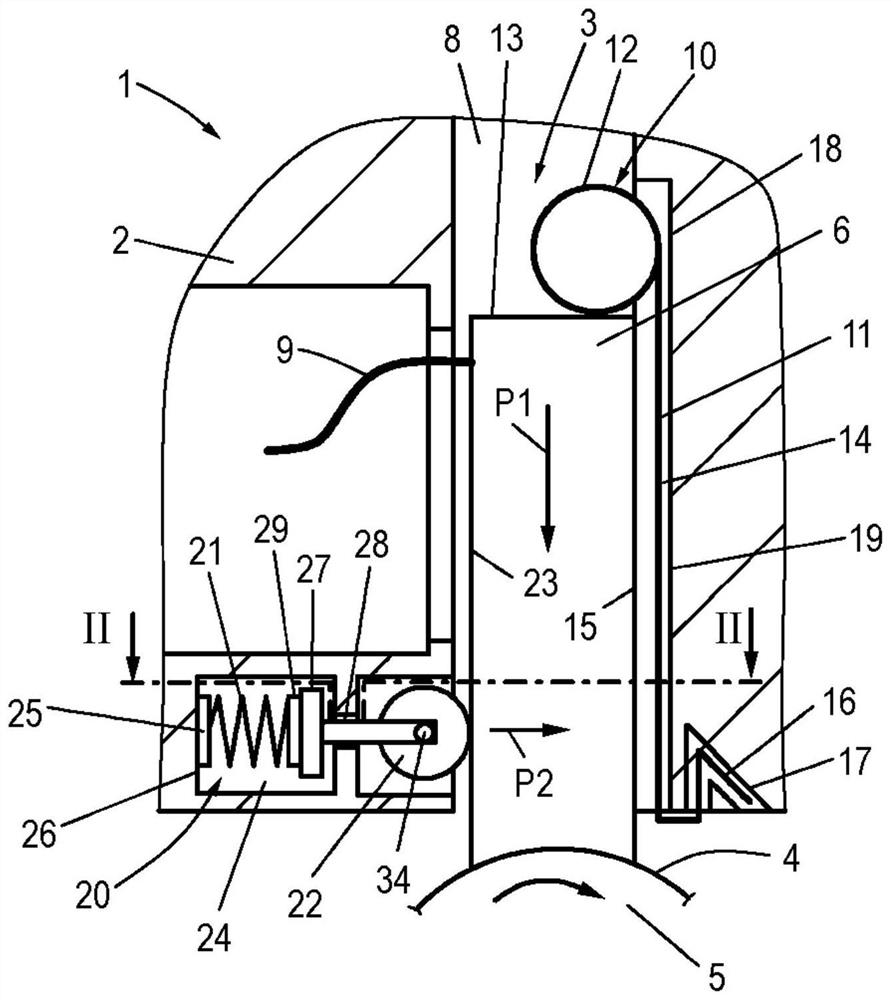

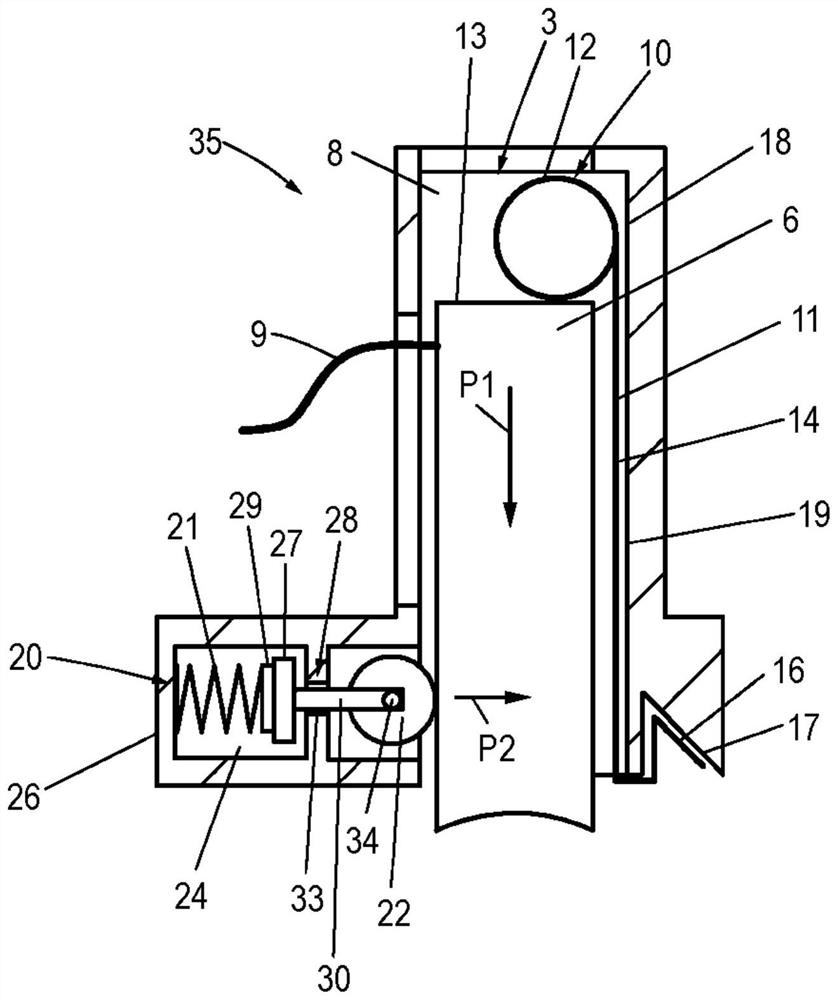

[0025] figure 1 A partial view of an electric machine 1 according to the invention is shown, which has a housing 2 in which a contact element arrangement 3 is arranged which makes electrical contact with a slip ring 4 of a rotor shaft 5 . For example, in the case of a separately excited synchronous machine, usually several, usually three, slip rings are arranged on the rotor shaft 5 , which are assigned to different phases and are in turn coupled to different conductor windings for generating the field field.

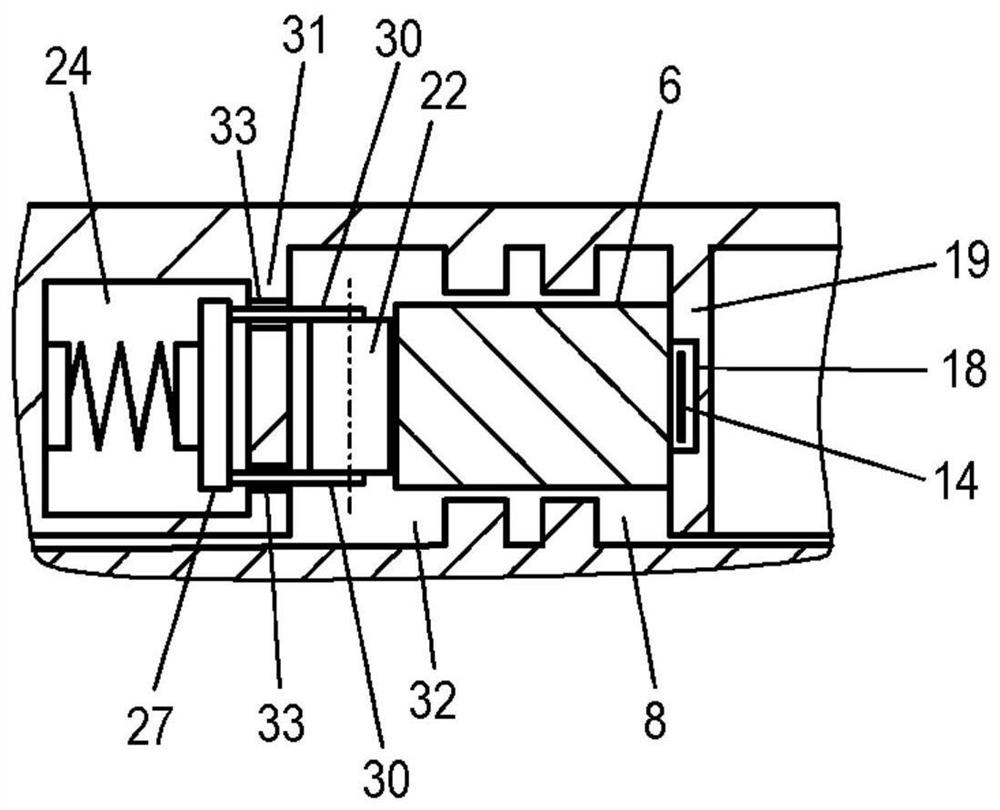

[0026] The contact element arrangement 3 has, on the one hand, contact elements 6 preferably in the form of carbon brushes. The contact element is here an elongated contact element 6 with a rectangular cross section, which has a groove-shaped geometry 7 on its underside corresponding to the geometry of the slip ring 4 rotating during operation, the contact element 6 is press fitted onto the slip ring. The contact element 6 is received in a guide 8 formed in the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com