Irradiation cross-linking low-smoke halogen-free fire-resistant wire and cable and making method thereof

A wire, cable and wire technology, applied in the field of manufacturing wires and cables by irradiation, can solve the problems of no flame retardancy, unfavorable personal safety and fire rescue, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] When adding low-smoke halogen-free flame retardant Mg(OH) to 100 parts of polyethylene (LDPE) 2 or AL(OH) 3 100-160 parts, 0.1-0.5 parts of antioxidant 300, and 1-1.5 parts of sensitizer, the cable made of this insulation layer or sheath formula can be used for indoor wire and cable.

example 2

[0046] When adding low-smoke halogen-free flame retardant Mg(OH) to 100 parts of polyethylene (LDPE) 2 or AL(OH) 3 When 100-160 parts, 2-3 parts of carbon black and 0.1-0.5 parts of antioxidant 300, the cables made of this insulating layer or sheath formula are used for outdoor overhead cables.

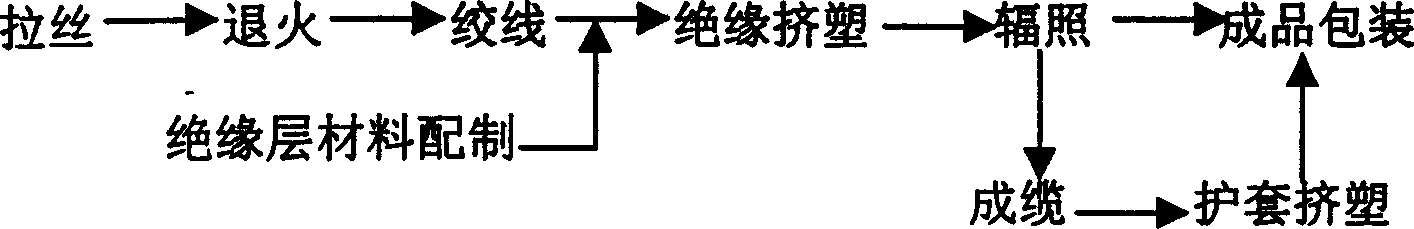

[0047] Such as figure 1 Shown is the block diagram of the production process of radiation crosslinked low-smoke halogen-free flame-retardant wire and cable of the present invention, according to figure 1 Specifically illustrate the manufacture method of the present invention, it comprises the steps:

[0048] The production method of the radiation crosslinked low-smoke halogen-free flame-retardant wire and cable of the present invention comprises the following steps:

[0049] 1. wire drawing the core metal, wherein the metal can be copper or aluminum;

[0050] 2. Anneal the wire-drawn metal and twist it into a core wire;

[0051] 3. Prepare the insulating layer raw materials, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com