Ozone disinfection equipment and ozone disinfection system

A technology of ozone disinfection and disinfection equipment, which is applied in the direction of disinfection, sanitation equipment for toilets, chemical instruments and methods, etc., can solve the problems of poor effect, inability to absorb ozone, and low efficiency, so as to improve safety and environmental protection, Concentrated cleaning is convenient and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

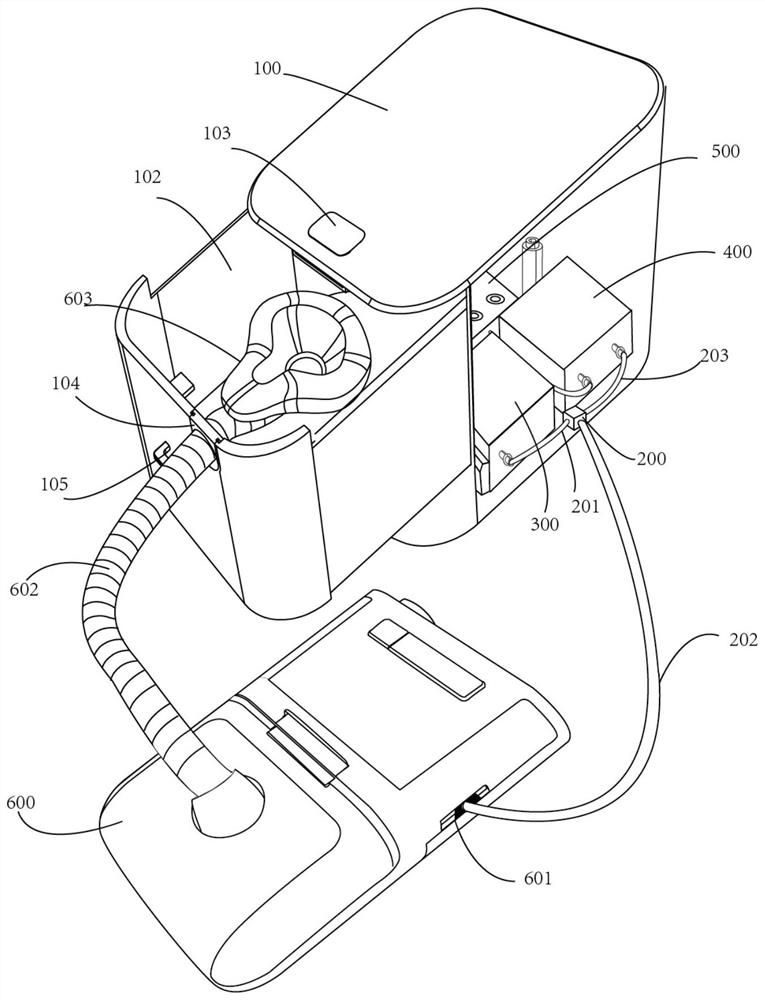

[0062] This embodiment provides an ozone disinfection device 100 . The ozone disinfection device 100 is particularly suitable for disinfecting breathing apparatus. The breathing apparatus includes a ventilator 600 , a hose 602 and a mask 603 connected in sequence. It can be understood that the ventilator 600 and the mask 603 are connected through a hose 602, the ventilator 600 and the hose 602 have a detachable connection structure, and the mask 603 and the hose 602 have a detachable connection structure.

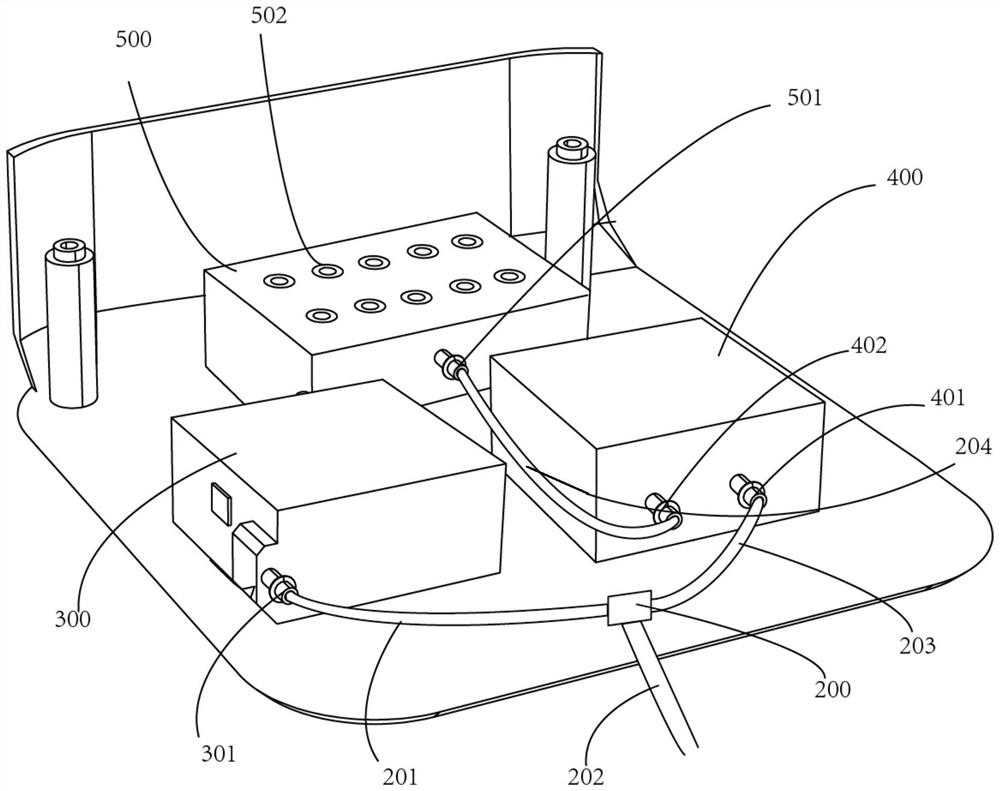

[0063] In this example, see figure 1 , the ozone disinfection equipment 100 includes: a disinfection sealed space 102 for accommodating the equipment to be disinfected or temporarily storing ozone, the disinfection sealed space 102 is communicated with an escape hole 104, and the avoidance hole 104 is used for the storage of the equipment to be disinfected The gas outlet end is inserted; the gas distribution unit 200 includes a first interface, a second interface and a th...

Embodiment 2

[0082] This embodiment provides an ozone disinfection system. The system includes a respirator 600, a flexible pipe 602, a mask 603, and the ozone disinfection equipment provided in Embodiment 1; the respirator 600, the flexible pipe 602 and the mask 603 are connected in sequence; The air inlet end 601 communicates with the second interface of the gas distribution unit 200 of the ozone disinfection equipment through the second pipeline 202; the gas outlet end of the hose 602 extends from the avoidance hole 104 into the disinfection sealed space 102 Inside; the mask 603 is housed in the sterile airtight space 102 . The flexible tube 602 and the face mask 603 are equipment matched with the ventilator 600 .

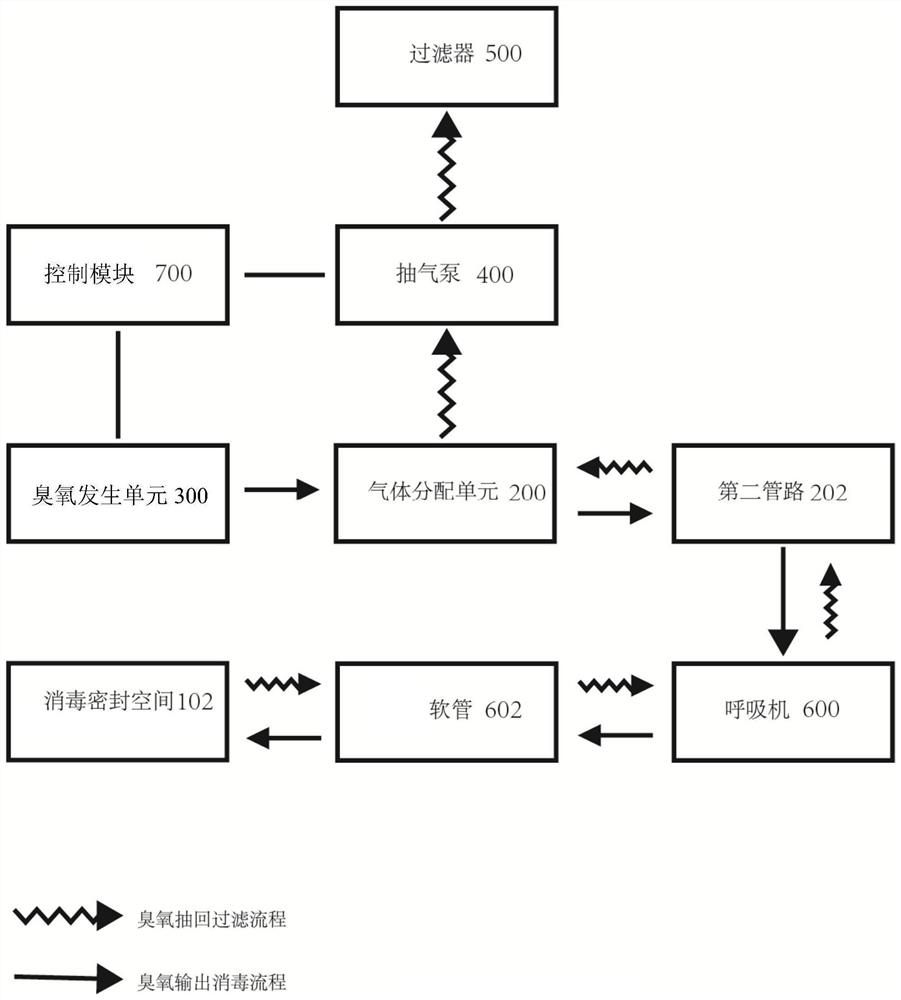

[0083] The control module 700 is used to control the ozone generating unit 300 to output enough ozone so that the ozone concentration in the sterilized airtight space 102 is not lower than the concentration value that can kill common germs inside the ventilator.

[0084] I...

Embodiment 3

[0089] This embodiment provides an ozone disinfection system. The ozone disinfection system includes a hose 602, a mask 603, and the ozone disinfection equipment provided in Embodiment 1; the hose 602 communicates with the mask 603; the inlet end 601 of the hose 602 passes through the second pipeline 202 communicates with the second interface of the gas distribution unit 200 of the ozone disinfection equipment; the gas outlet end of the hose 602 extends into the disinfection sealed space 102 from the avoidance hole 104; the mask 603 is housed in the In the above-mentioned disinfection sealed space 102. The flexible tube 602 and the face mask 603 are equipment matched with the ventilator 600 .

[0090] In this embodiment, the control module 700 is used to control the ozone generating unit 300 to output enough ozone so that the ozone concentration in the sterilized sealed space 102 is not lower than the concentration value that can kill conventional germs inside the ventilator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com