Scraper conveying device for coal mine

A technology of transportation device and scraper, which is applied in the direction of transportation and packaging, conveyor, loading/unloading, etc. It can solve the problems of unadjustable, fixed nozzle angle, and increased work burden of staff, so as to achieve convenient use, avoid pollution of the environment, Solve the effect that the angle is fixed and cannot be adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

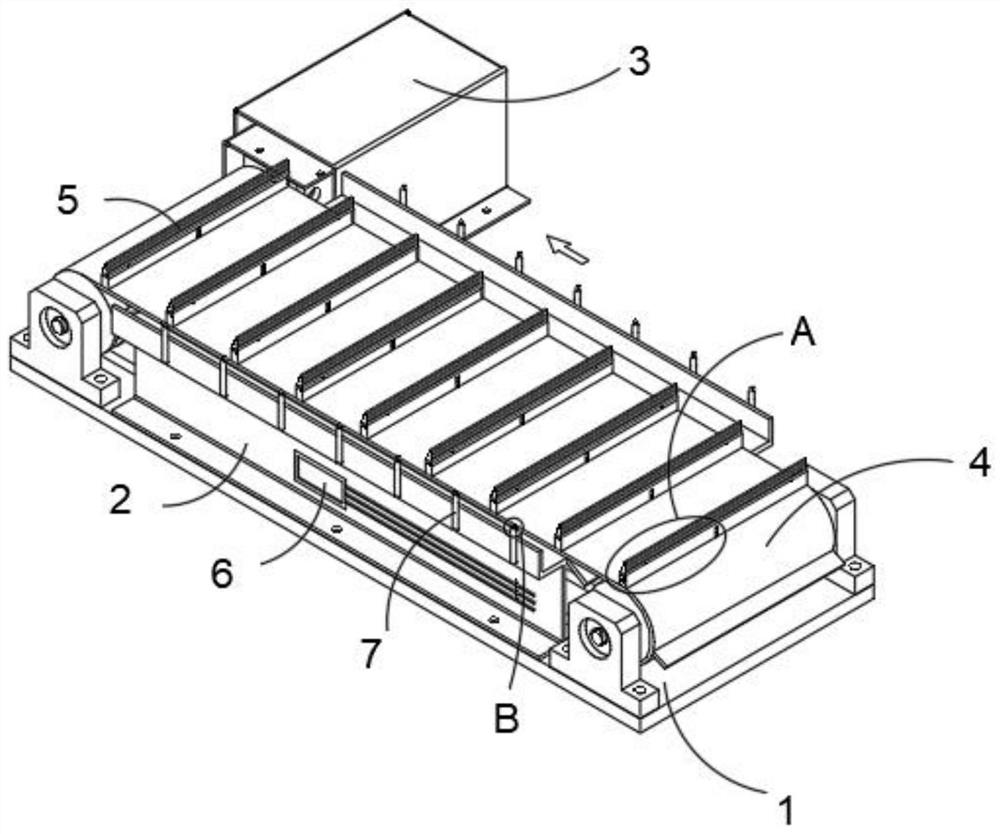

[0029] This example gives the specific structure of the cabinet, the inner case, and the rack assembly, such as Figure 1-4 As shown, a coal mine is used for a blade transportation device, including:

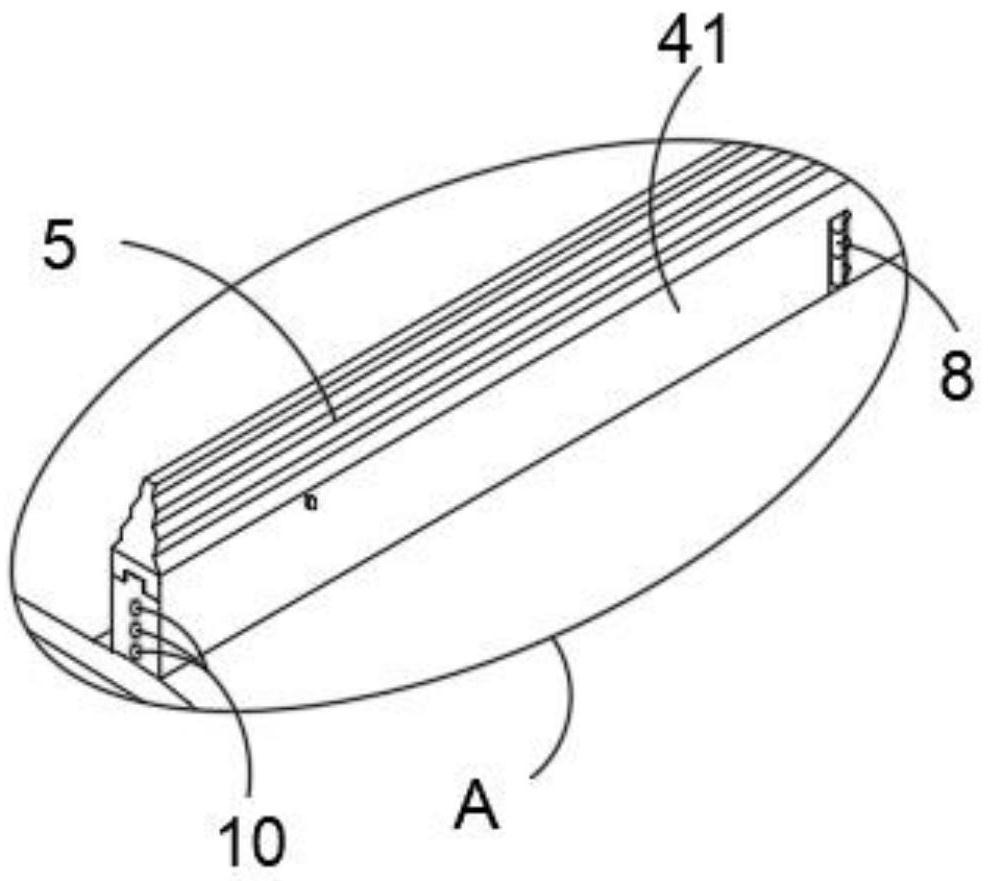

[0030] The chassis 1 is provided with a transport belt 4, and the side side of the chassis 1 is mounted with a driving motor 3 for driving the transport tape 4, and the outer surface of the transport tape 4 is evenly provided with several convex tape 41, which convex The belt 41 is used to position the blade member 5, and the blade member 5 is set to the surface of the tape 11, and the bolt is fixed;

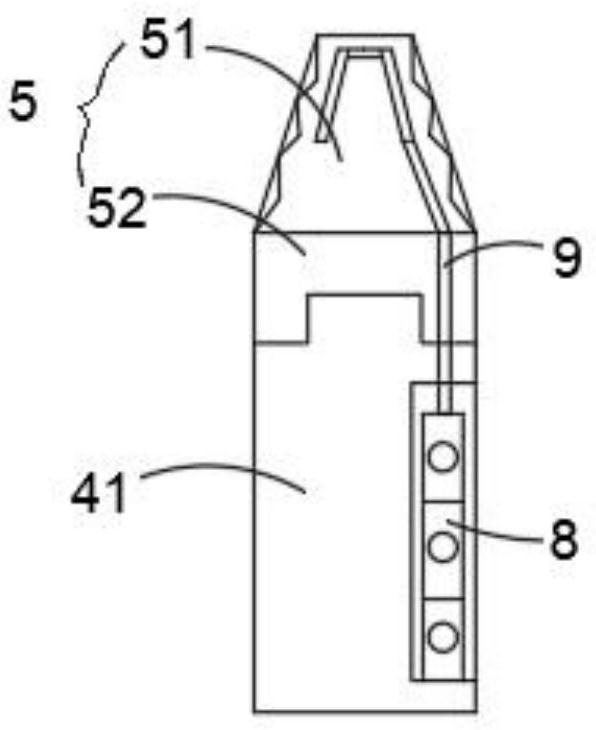

[0031] The blade member 5 is fixed to the top end of the tape 41, and the blade member 5 includes a folding capsule 51 and a connecting seat 52 for connecting the folding bag 51 and the tape 41, and the middle of the convex strip 41 is embedded. The pipe group 8, and the air supply pipe group 8 are used to carry the folding capsule 51 folded up and down.

[0032] Refer figure 2 As show...

Embodiment 2

[0043] The specific structure given in this example, such as figure 1 As shown, the side baffle 2 is fixed to the side of the bottom frame 1, and the middle end of the side baffle 2 is embedded is equipped with a gas pump 6 that is inflating the inflatable pump 6 of the inflatable pipe group 8, and has a number of pieces in the outer wall of the side baffle 2. Water pipe 7, each of the water pipes 7 and the external water source are connected by a water pipe.

[0044] Refer Figure 4 As shown, the distal end of the water pipe 7 is provided with a nozzle 13, and the rod 11 is provided between the top end of the respective water pipes 7, and the adjustment rod 11 is used to adjust the deflection angle of the nozzle 13.

[0045] Refer Figure 4 As shown, the nozzle 13 is a hollow cylindrical vesicle, and the nozzle end of the nozzle 13 is fitted to the outer surface thereof.

[0046] In the case of specific use,

[0047] By rotating the adjustment rod 11, the connection post 14 is furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com