In-place detection device and AGV forklift

A detection device and forklift technology, applied in the direction of lifting device, etc., can solve the problems of small detection range and insufficient function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

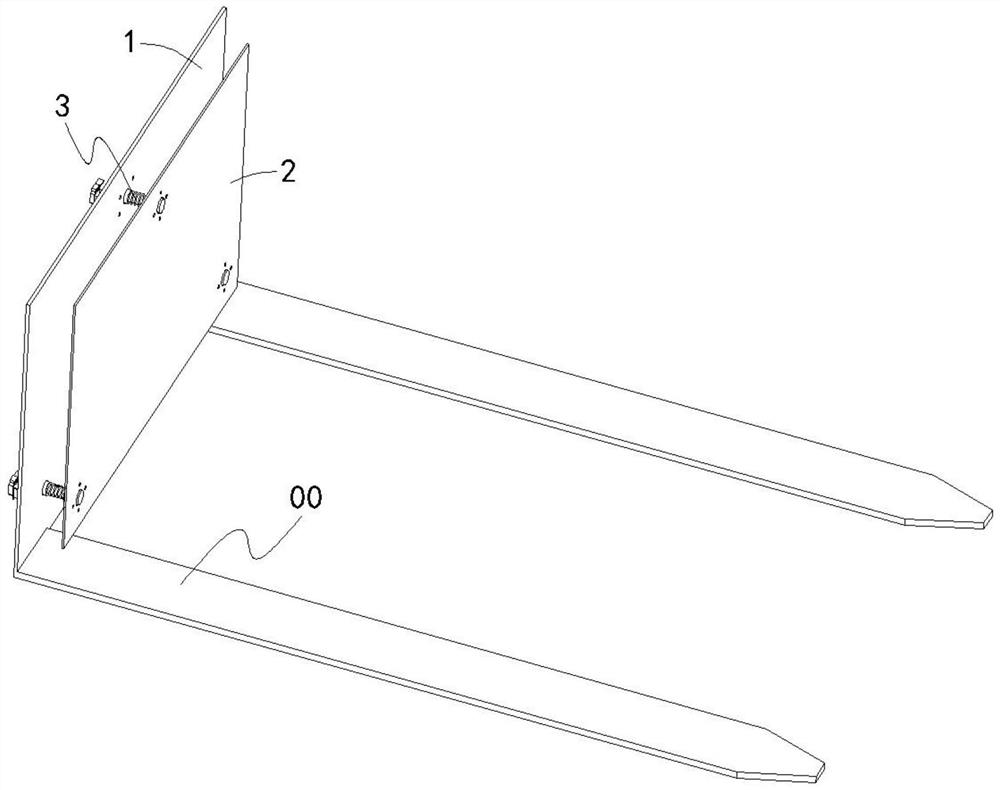

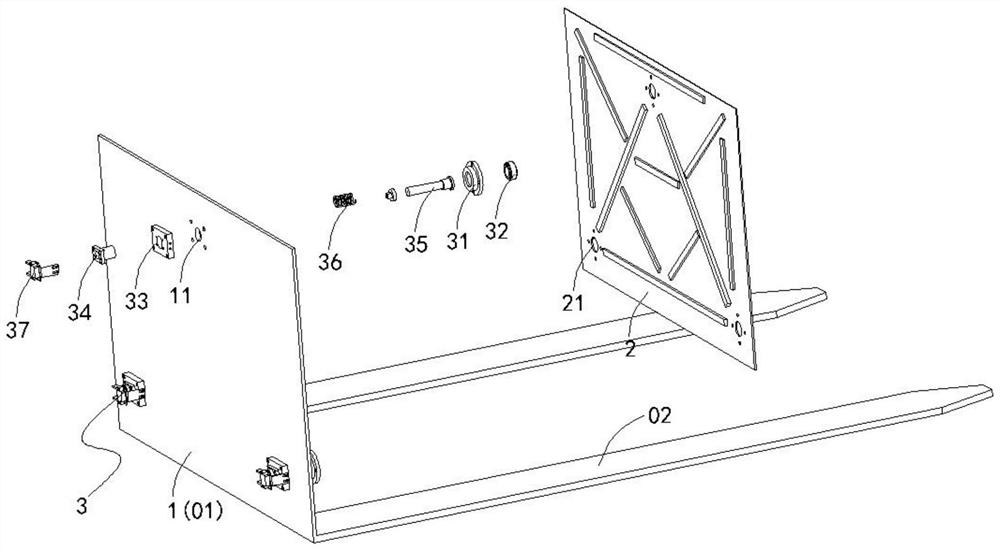

[0027] One kind AGV forklift, see Figure 1 to 4 00, and the detecting means in place, the fork 00 is provided in the truck body active front side of the truck which is provided in place of the body detecting means (not shown), the fork on the fork 00, the detection means for detecting place goods 02 cargo pallets on the fork tines 00 is in place.

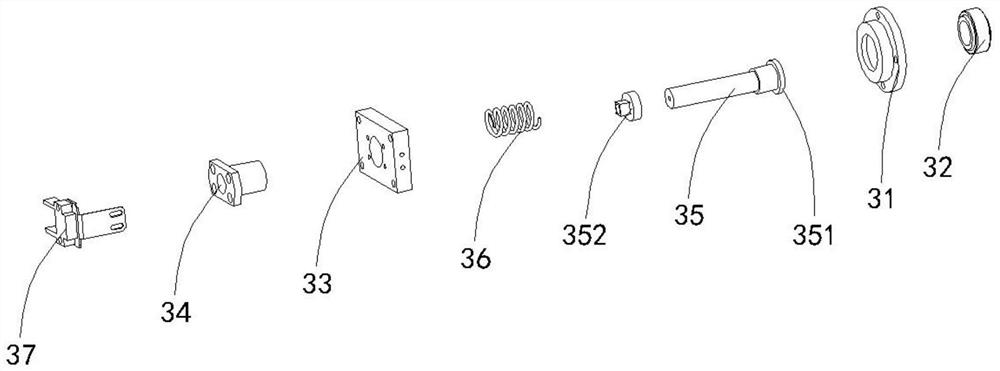

[0028] See Figure 1 to 4 , Detecting means comprises a base 1 in place, the movable plate 2, the joint assembly 3. Wherein, the base 1 is mounted on the fork backplate 0100 is provided on the base 1 with a first mounting hole 11; in the present embodiment, there are three first mounting hole 11 is provided on the base 1, a base integrally formed with the backing plate 01, backing plate 01 that is fork 00 directly as the base-position detection apparatus 1. Moving plate 2 is provided with a buffer space between the front side, the movable plate 2 of the base 1 and the base 1 is provided with a second mounting hole 21 in the moving plate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap