Lifting type tail yarn retaining device and control method

A tail-reserving, lift-type technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of long manual operation time, not suitable for large-scale automated workshops, etc., and reduce the operation time. The effect of difficulty, ease of implementation, and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

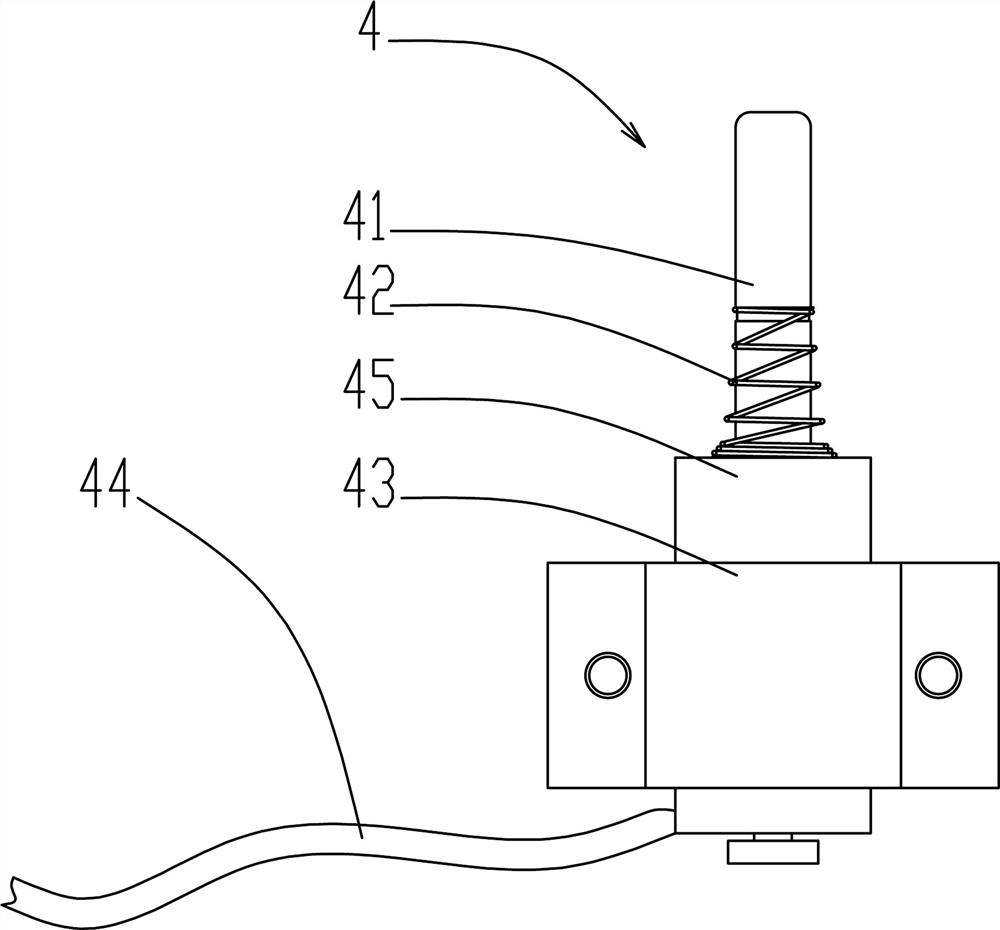

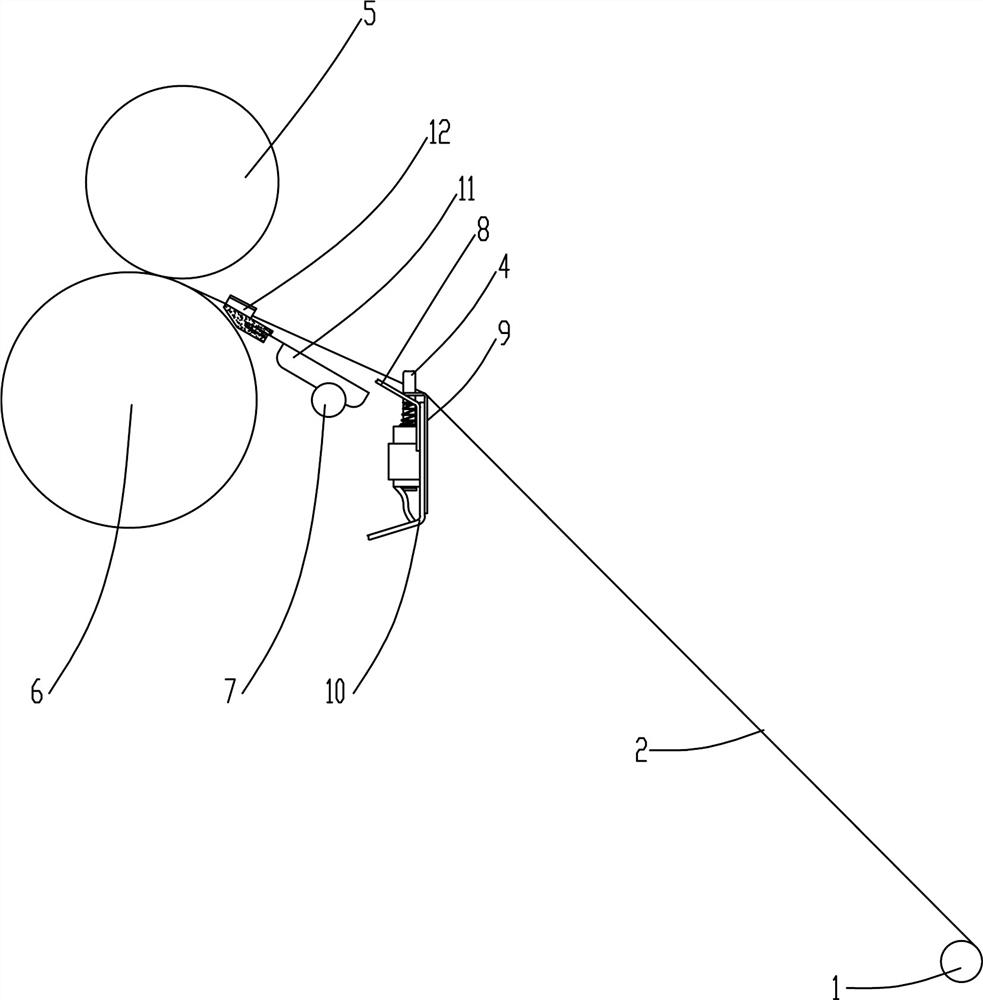

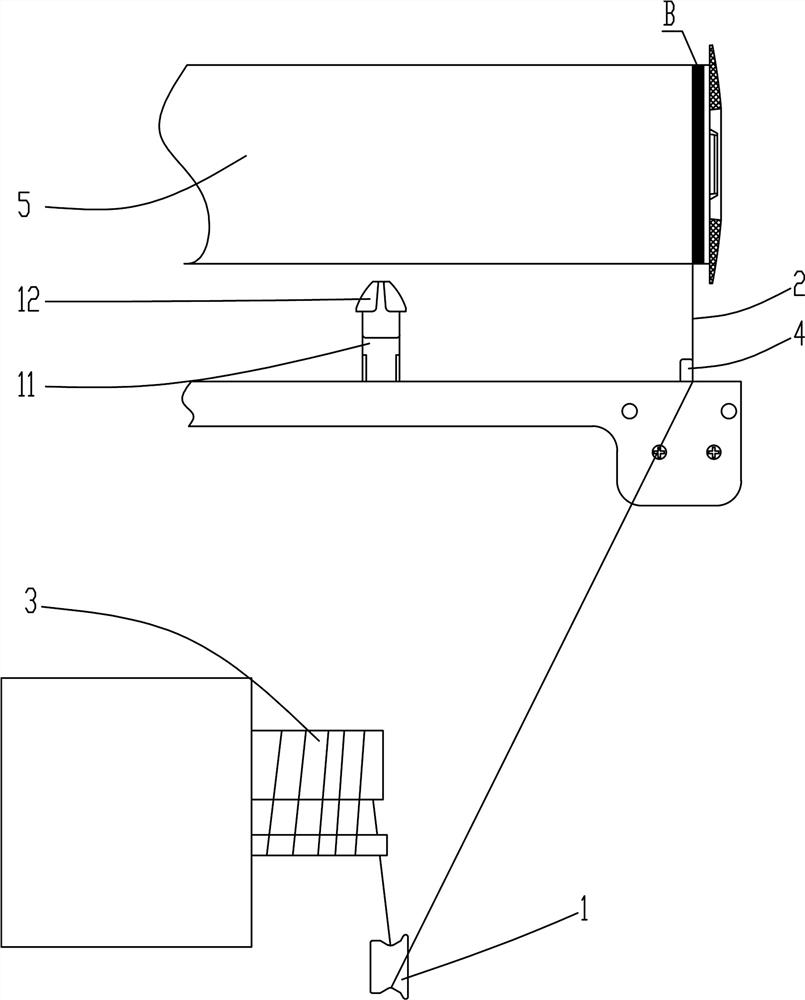

[0030] Such as Figure 2~4 Among them, a lift-type tailing yarn device includes a reel driving roller 6 and a reciprocating yarn guide device, and a tailing yarn device 4 is provided on the upstream side of the reciprocating yarn guide device near the tailing yarn section B at the end of the yarn drum 5 , the tail yarn device 4 is provided with a liftable lift bar 41, and the lift bar 41 is higher than the common tangent between the yarn guide plate 9 and the reel drive roller 6 when it is raised, so as to block the yarn 2 and make the yarn The line cannot move laterally, and the lift bar 41 is lower than the common tangent between the yarn guide plate 9 and the drum drive roller 6 when lowered, so as to release the yarn 2 . With this structure, it is realized to use the tail yarn keeping device 4 to block the yarn 2 after starting to carry out the tail yarn keeping operation, and to release the yarn 2 after completion.

[0031] The preferred solution is as figure 1 Among th...

Embodiment 2

[0040] A control method using the above-mentioned lifting type tail yarn device, comprising the following steps:

[0041] S1, the overfeeding parameter of yarn 2 is set, and the time parameter of leaving tail yarn is set by calculation, that is, the time for lifting and lowering bar 41 to block yarn 2; the time of leaving tail yarn in this example is set to 7s, this The time has determined how much the yarn 2 that stays tail yarn segment B is wound. It is related to the number of winding turns of the yarn 2 on the overfeeding device 3, the overfeeding ratio of the yarn 2, and the winding speed of the mandrel drive roller 6.

[0042] S2, hang the yarn 2 on the side of the lift bar 41 close to the end of the yarn reel 5;

[0043] S3, wind the tail yarn to the end of the yarn reel 5, and press the start button of the overfeeding device 3;

[0044] S4, the yarn 2 is winding the tail yarn, until the end of the set tail yarn time, the lift lever 41 descends to let the horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com