Eccentric vibration type hydraulic pulse generating device

A technology of hydraulic pulse and generating device, which is applied to the driving device for drilling in the borehole, vibration drilling, drilling tools, etc., can solve the problems of high cost and inapplicability to special operations, and achieve low cost, improve drilling effect, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

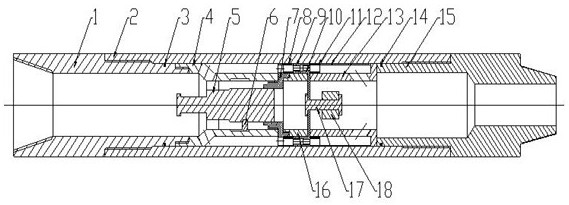

[0029] An eccentric vibration type hydraulic pulse generating device is composed of three parts: an outer cylinder, an inner cylinder and a pulse vibration device, wherein:

[0030] The outer cylinder is mainly composed of an upper joint 1, an outer cylinder body 2, and a lower joint 15 connected in sequence;

[0031] The inner cylinder includes an upper shunt joint 4, an inner cylinder sealing plug 5, a locking block 6, an upper cylinder body 7, a lower cylinder body 13 and a rotor fixing ring 16; wherein, the upper shunt joint 4 is a hollow cylinder with a thick top and a thin bottom. The upper end of the upper shunt joint 4 is connected to the upper joint 1, and the lower end of the upper shunt joint 4 is connected to the upper cylinder 7; the upper cylinder 7 is a hollow cylindrical structure, and the lower end is connected to the rotor The fixed ring 16 is connected, and the outer periphery is provided with a fixed limit block; the lower cylinder 13 is a hollow cylindrica...

Embodiment 2

[0034] On the basis of embodiment 1 further include:

[0035] The turbine stator 9 and the turbine rotor 10 are defined by the upper bearing 8 above the turbine stator 9 and the lower bearing 11 below the turbine rotor 10 on the periphery of a fixed ring 16 .

[0036] A compression ring 12 is arranged between the lower part of the lower bearing 11 and the thick diameter of the lower part of the lower cylindrical body 13 .

[0037] The belonging pressing ring 12 is a thin-walled ring.

[0038] The turbine rotor 10 and the turbine stator 9 have a single-stage turbine structure, and the relative flow areas of the turbine stator 9 and the turbine rotor 10 have periodic changes.

[0039] The upper part of the upper cylinder 7 is an inner convex ring structure, which is inserted into the upper shunt joint 4; the upper part of the inner cylinder sealing plug 5 is provided with a fishing head, and the lower part forms a sealed plug connection with the inner convex ring structure of t...

Embodiment 3

[0042] see figure 1 , 2 , an eccentric vibration type hydraulic pulse generating device consists of three parts: an outer cylinder, an inner cylinder and a pulse vibration device. The outer cylinder includes upper joint 1, outer cylinder body 2, sealing ring 3, and lower joint 15; the inner cylinder includes upper shunt joint 4, inner cylinder sealing plug 5, locking block 6, upper cylinder body 7, upper bearing 8, and lower bearing 9. Compression ring 12, lower cylinder 13, sealing ring 14, rotor fixing ring 16; the pulse vibration device includes turbine stator 9, turbine rotor 10, eccentric shaft 17 and eccentric wheel 18. See figure 1 .

[0043]Among them: the upper joint 1 and the outer cylinder 2 are connected by the upper sealing ring 3 and the thread, the outer cylinder 2 and the lower joint 15 are connected by the lower sealing ring 14, and the upper shunt joint 4 and the inner cylinder sealing plug are arranged inside the outer cylinder 2 5. Locking block 6, uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com