Peanut cleaning machine

A washing machine and peanut technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of peanut breakage and low efficiency of manual cleaning, and achieve the effect of preventing clogging, improving efficiency and increasing residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

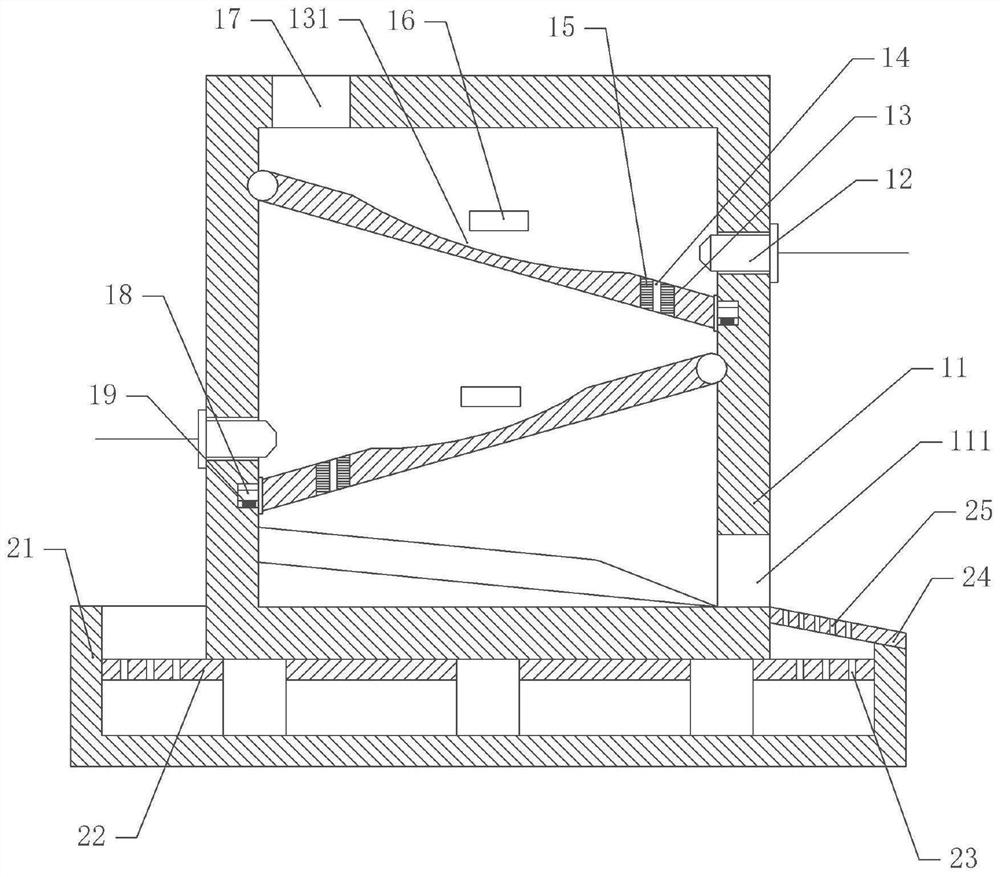

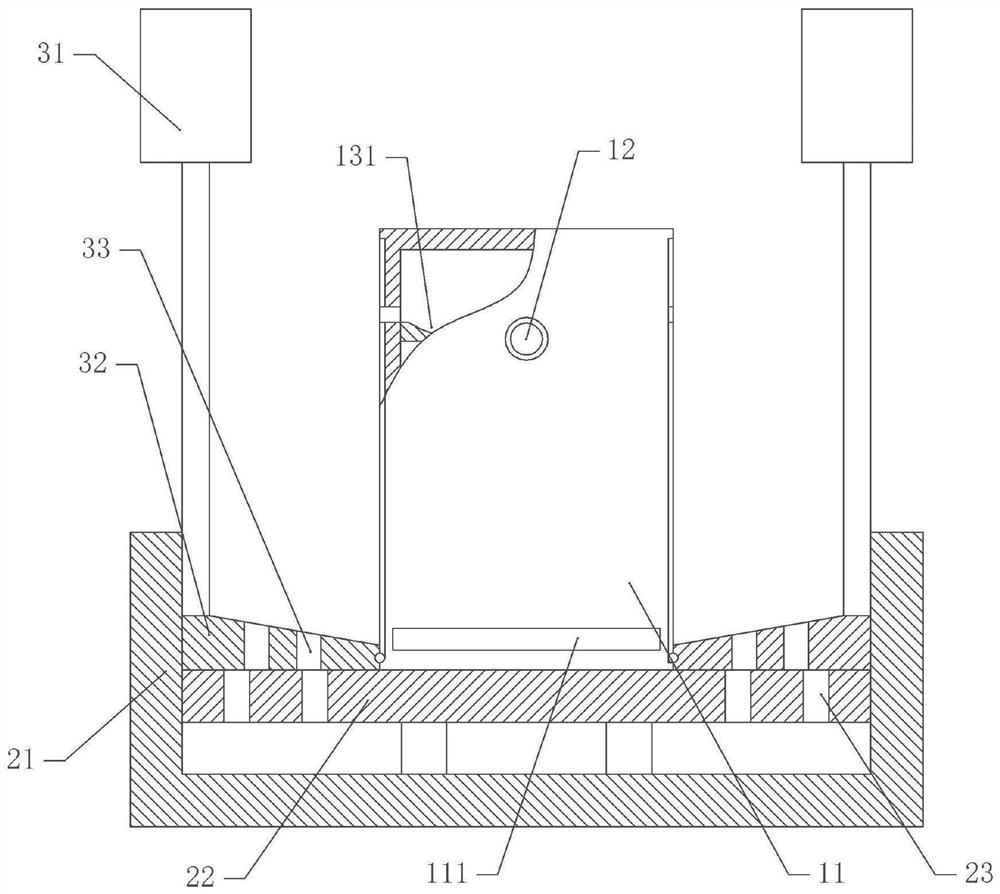

[0038] A peanut cleaning machine, as attached figure 1 And attached figure 2 Shown, comprise recovery pool 21 and the cleaning box 11 that is fixed in recovery pool 21, form recovery cavity between cleaning box 11 and recovery pool 21, the bottom of cleaning box 11 is fixed with sieve plate 22, has several on the sieve plate 22 Sieve hole 23.

[0039] The top of the cleaning box 11 has a feed hole, and the cleaning box 11 is provided with some support plates 13 positioned below the feed port 17. Several support plates 13 are arranged vertically along the cleaning box 11. One end of the support plate 13 is high and supports The other end of the plate 13 is low, and the adjacent supporting plates 13 form a V-shaped structure, and the opening of the V-shaped is facing one side of the cleaning box 11 .

[0040] The high end of the support plate 13 is hinged with the cleaning box 11, and the low end of the support plate 13 is provided with a vibrating mechanism. The vibrating me...

Embodiment 2

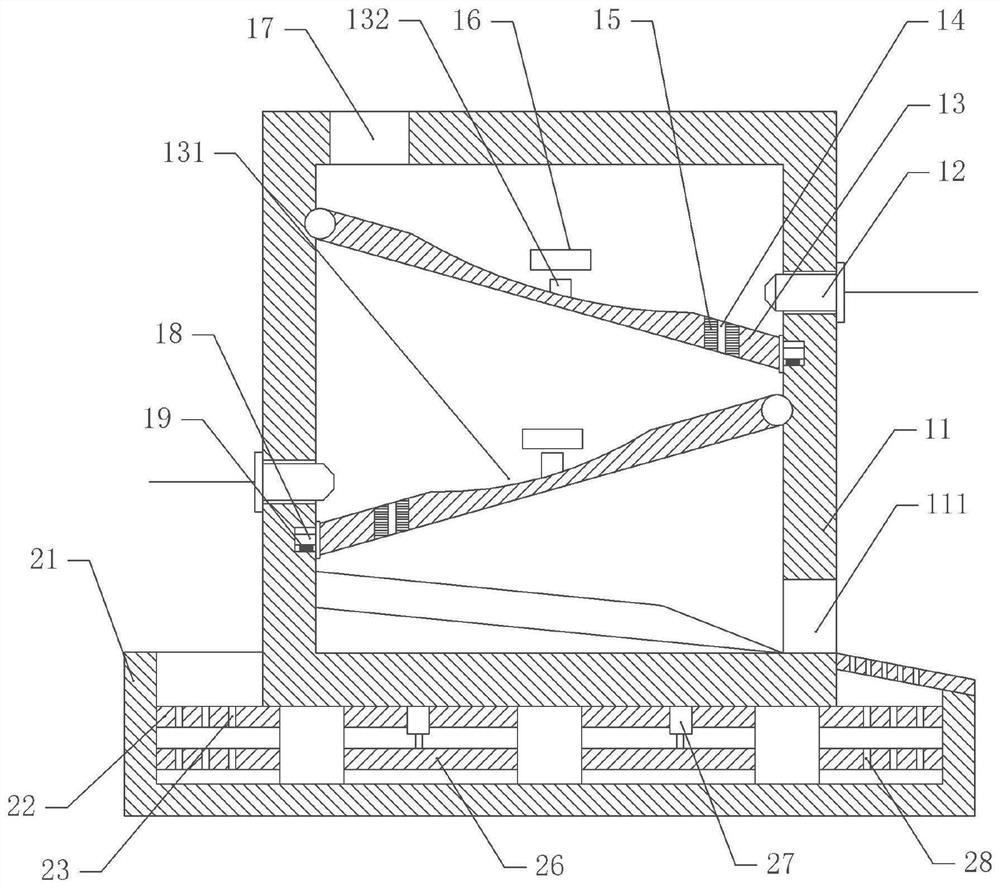

[0050] The difference between embodiment two and embodiment one is that, as attached image 3 As shown, a secondary sieve plate 26 is arranged below the sieve plate 22, a second cylinder 27 is fixed on the cleaning box 11, the output shaft of the second cylinder 27 is fixedly connected with the secondary sieve plate 26, and the secondary sieve plate 26 is opened. There are several secondary screen openings 28 . Both sides of the support plate 13 are fixed with scrapers 132 below the screening opening 16 .

[0051] In this embodiment, if the peanuts dropped onto the sieve plate 22 have a diameter smaller than the sieve hole 23, they will fall onto the secondary sieve plate 26, and if the peanuts with a diameter larger than the sieve hole 23 remain on the sieve plate 22, then, Peanuts are screened multiple times. The second cylinder 27 vertically reciprocates sliding with the secondary sieve plate 26 to adjust the distance between the secondary sieve plate 26 and the sieve pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com