Display panel, manufacturing method thereof and display device

A technology for display panels and manufacturing methods, applied in the fields of nonlinear optics, instruments, optics, etc., can solve problems affecting display panel display effects, short circuits, test traces with electrification, etc., so as to improve display effects and avoid contact short circuits , the effect of reducing the possibility of short-circuit problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

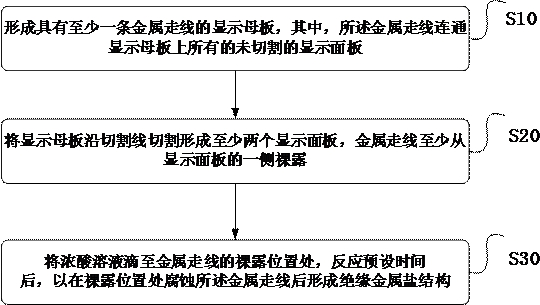

[0050] like figure 1 As shown, as the first embodiment of the present application, a method for manufacturing a display panel is disclosed, including steps:

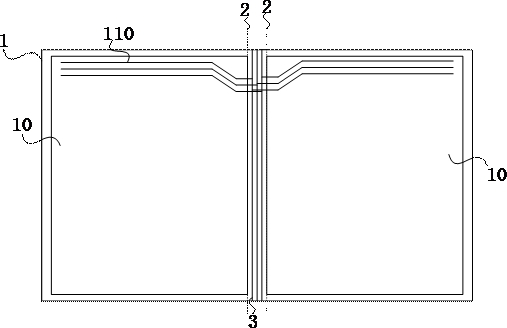

[0051] S10: forming a display motherboard with at least one metal trace, wherein the metal trace communicates with all uncut display panels on the display motherboard;

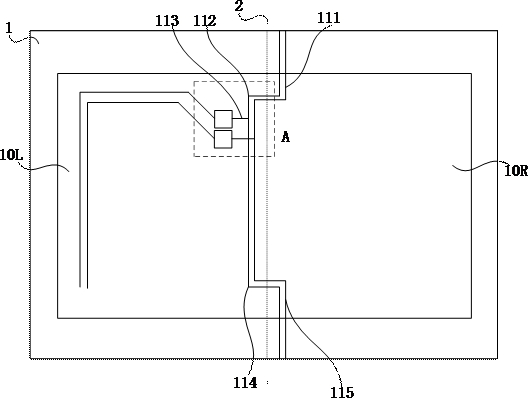

[0052] S20: cutting the display motherboard along the cutting line to form at least two display panels, and the metal traces are exposed on at least one side of the display panels;

[0053] S30: drop the concentrated acid solution onto the bare position of the metal trace, and react for a preset time, so as to form an insulating metal salt structure after corroding the metal trace at the bare position.

[0054] In this application, the concentrated acid solution and the bare position of the metal wiring are subjected to oxidation-reduction reaction to generate the corresponding insulating metal salt structure, that is, the metal wiring of the insulating...

Embodiment 2

[0087] Specifically, there are many options for the location of corrosion: such as Figure 8 As shown, as the second embodiment of the present application, another method for manufacturing a display panel is disclosed, including steps:

[0088] S10: forming a display motherboard with at least one metal trace, wherein the metal trace communicates with all uncut display panels on the display motherboard;

[0089] S20: cutting the display motherboard along the cutting line to form at least two display panels, and the metal traces are exposed on at least one side of the display panels;

[0090] S32: directly dripping the concentrated acid solution to the exposed area corresponding to the metal wiring on the side of the display panel;

[0091] S40: Perform a cleaning step after a preset time.

[0092] Corresponding to this embodiment, a display panel is disclosed. The display panel includes: a first substrate, at least one metal wiring and an insulating layer, the metal wiring is...

Embodiment 3

[0095] like Figure 9 As shown, as the third embodiment of the present application, the present application also discloses a display device, the display device 400 includes a conductive tape 420, a circuit board 410 and the above-mentioned display panel 10, and the conductive tape 420 corresponds to the display panel 10, the circuit board 410 is bound on the display panel. The conductive tape in this embodiment can be directly attached to the side of the display panel, and the exposed positions corresponding to the metal traces can be directly in contact with the metal traces without short circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com