Braking method of high-rotating-speed handle, and controller

A high-speed, controller technology, used in motor control, AC motor control, AC motor acceleration/deceleration control, etc., can solve problems such as inability to brake quickly, and achieve the purpose of avoiding secondary damage, widely using value, and protecting safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of a high-speed handle braking method and controller according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. The method and its effect are described in detail below.

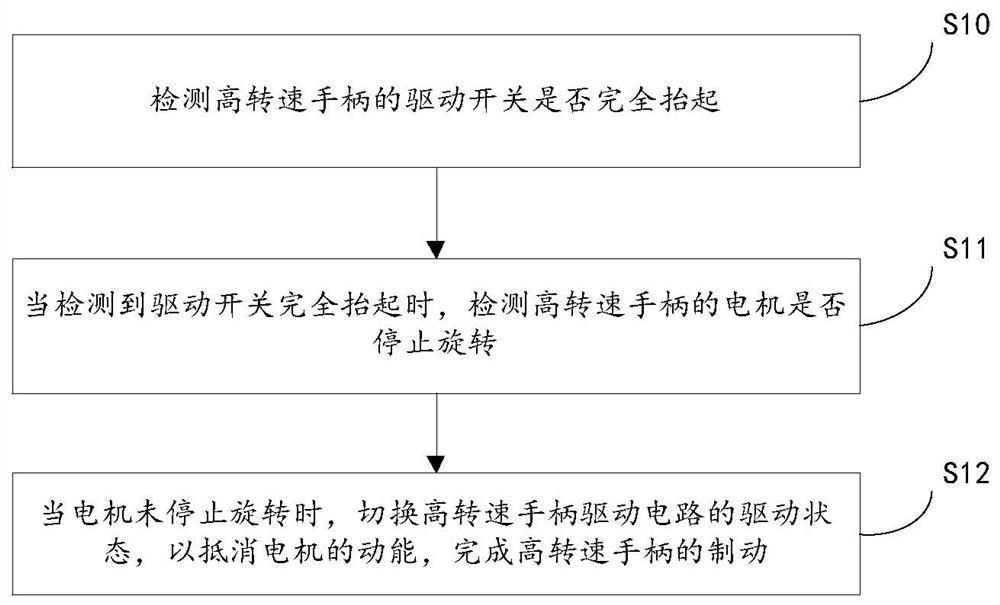

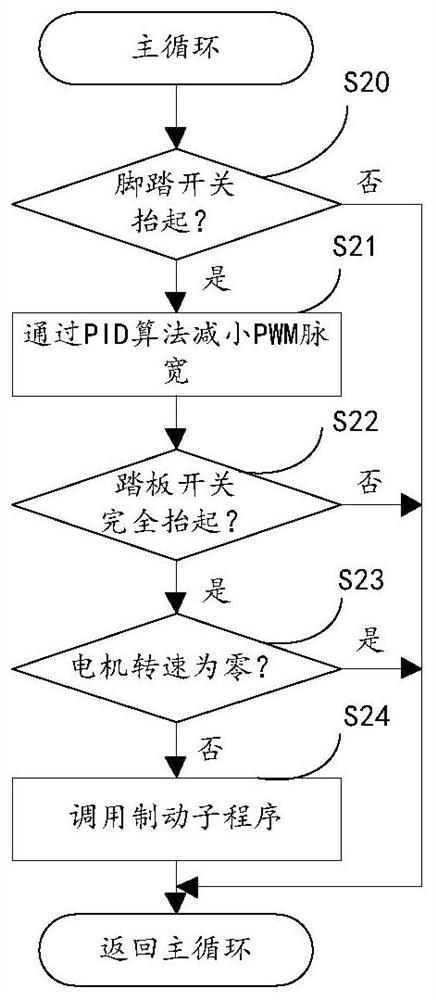

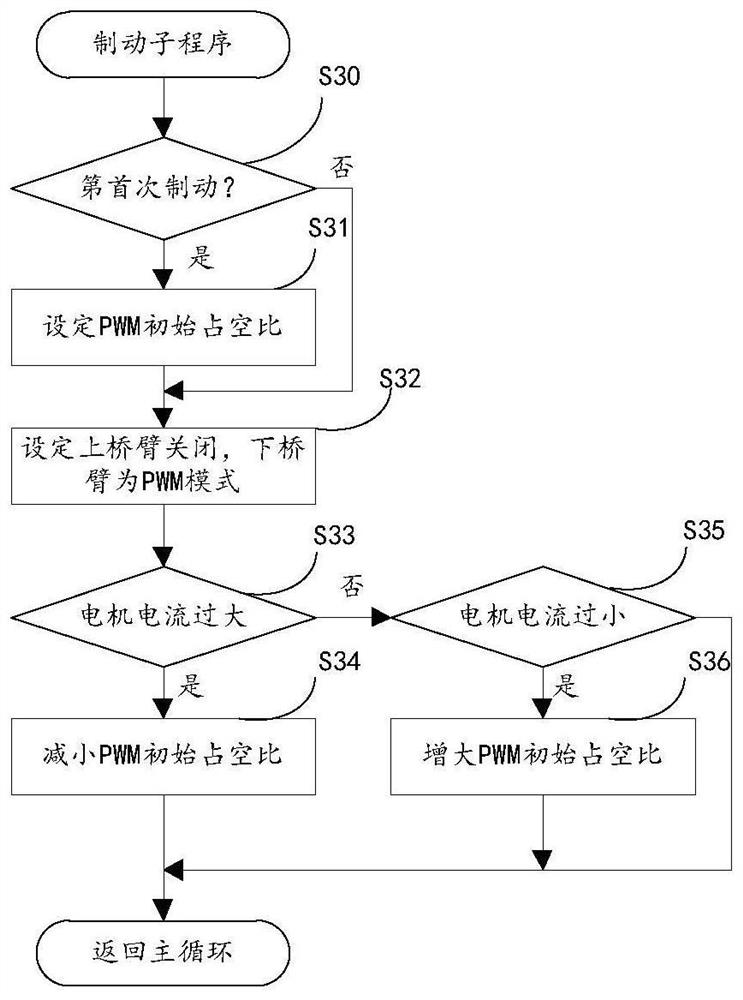

[0044] An embodiment of the present invention provides a braking method based on a high-speed handle, such as figure 1 shown, including:

[0045] Step S10, detecting whether the drive switch of the high-speed handle is fully lifted.

[0046] During the use of the high-speed handle, the opening, closing and speed regulation of the high-speed handle are usually controlled by a foot switch. When the foot switch is depressed, the high-speed handle is turned on; when the foot switch is fully lifted, the operation of the high-speed handle is turned off. Of course, the switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com