Camera module and assembling method

The technology of a camera module and assembly method, which is applied in the field of optics, can solve the problems that the resolution cannot be guaranteed, and the glue thickness of the camera module is different.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

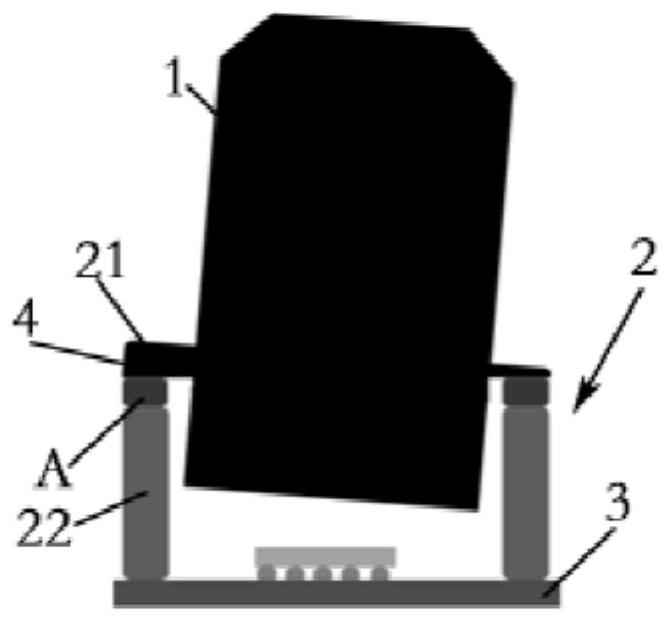

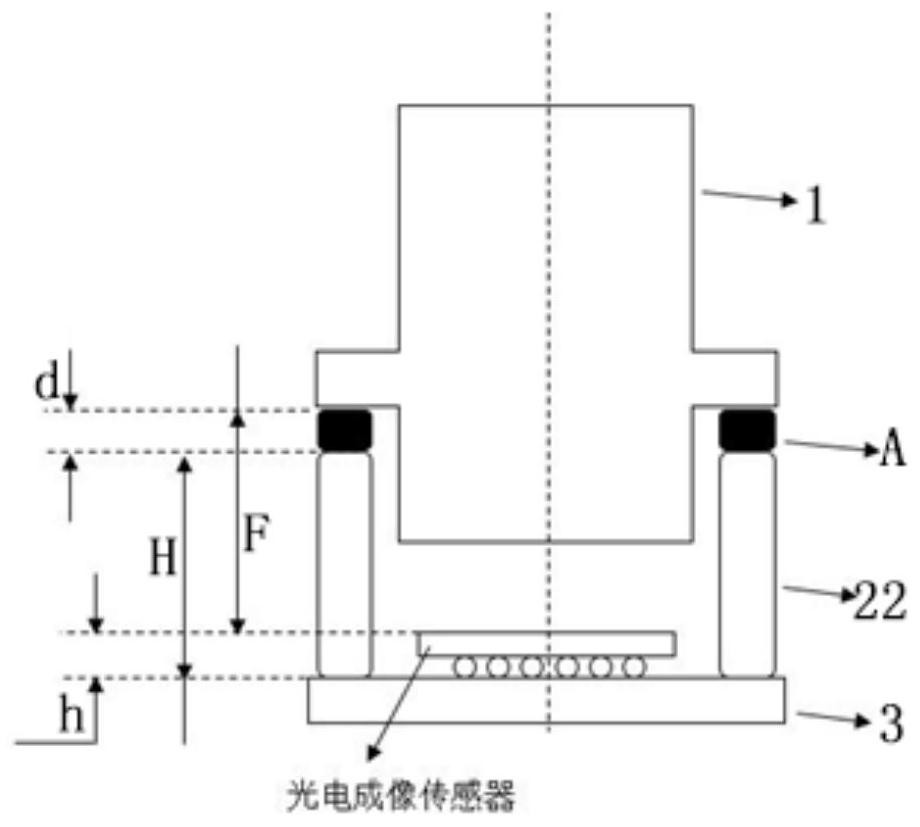

[0058] combine Figure 1-Figure 5 As shown, according to the first embodiment of the present invention, both the first connecting portion 21 and the second connecting portion 22 of the connecting piece 2 are separate components. In this embodiment, the first connecting portion 21 is a connecting flange, the first connecting portion 21 is fixedly connected to the lens 1 , and the second connecting portion 22 is a mirror base. Such as figure 2 As shown, in an ideal state, the base is assembled with the circuit board 3, and then the lens 1 is AA-assembled with the base and the circuit board 3. After finding the best imaging position of the lens, fill the glue (connecting glue layer) to the first The connection part 21 is fixedly connected to the second connection part 22 .

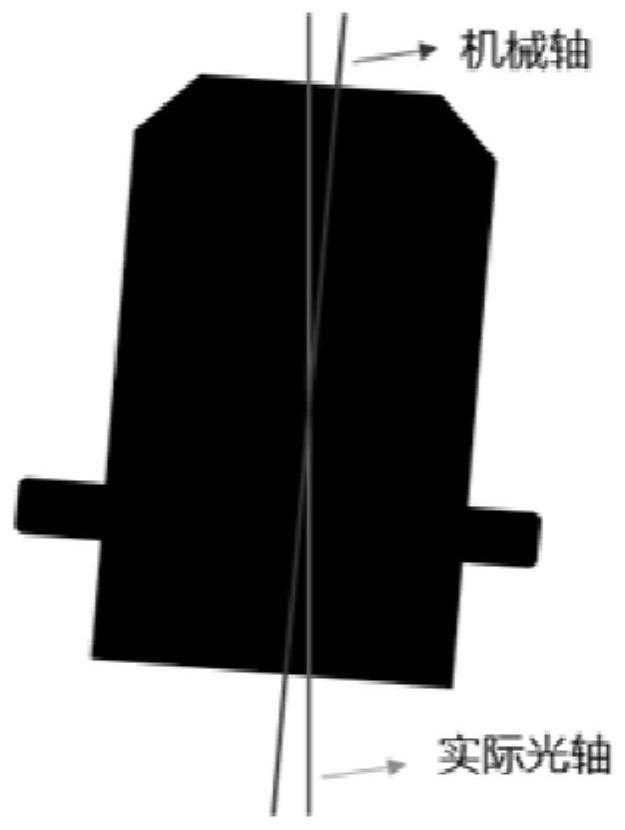

[0059] combine image 3 and Figure 4 As shown, however, in the actual assembly process of the camera module, there is a certain angle deviation between the mechanical axis of the lens 1 and the actual o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com