Welding tool for depressed center flat car center sill assembly

A technology of welding tooling and flat car, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can improve reliability and efficiency, avoid large space, and do not affect the welding operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

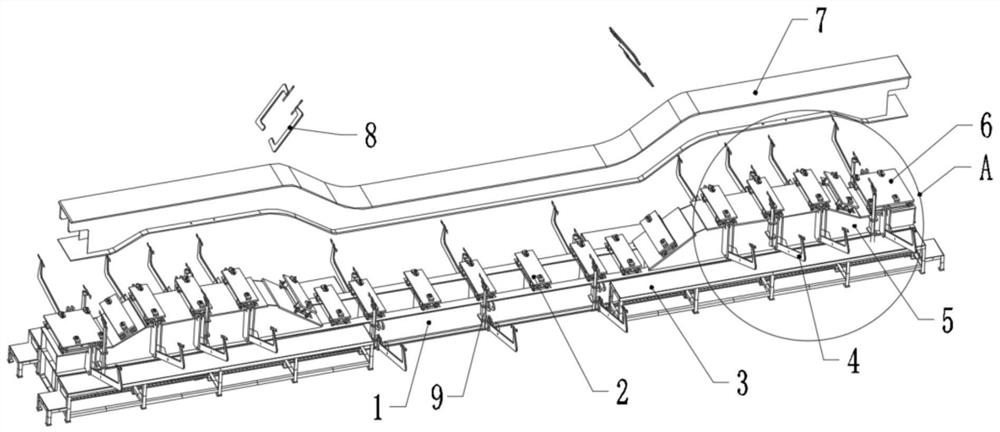

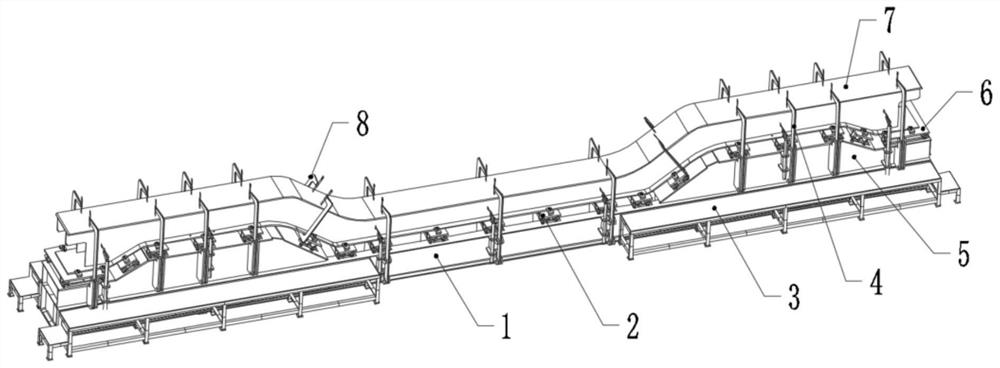

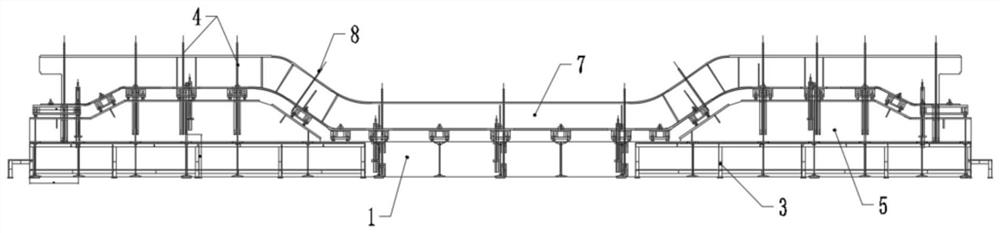

[0028] A welding tool composed of the middle beam of a flat car with a concave bottom, such as Figure 1-3 As shown, it includes an I-beam underframe 1, a box body 5 is fixedly connected above the two ends of the I-beam underframe 1, and several first adjustable Positioning platform 2, the top of one end of the box body 5 is fixedly connected with a second adjustable positioning platform 6; the top of the first adjustable positioning platform 2 and the second adjustable positioning platform 6 is fixed with a concave bottom flat car to be welded The center beam 7, the two ends of the center beam 7 of the concave-bottom flat car are matched with the boxes 5 at the two ends of the I-beam chassis 1, and the concave bottom position of the center beam 7 of the concave-bottom flat car is connected with the two boxes 5 The I-beam underframe 1 between them is compatible. The sides of the two ends of the I-beam underframe 1 are fixed with pedal platforms 3, and the number of the pedal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com