Full-tempered vacuum glass and preparation method thereof

A vacuum glass and tempering technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve problems such as hidden air leakage and reduced sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

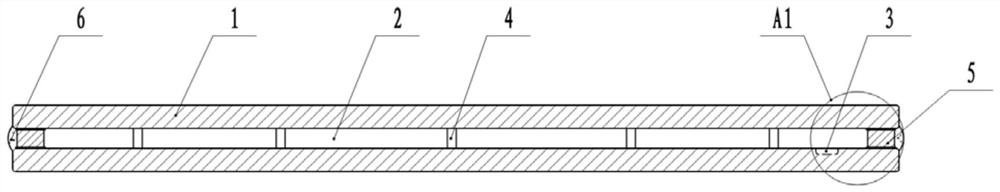

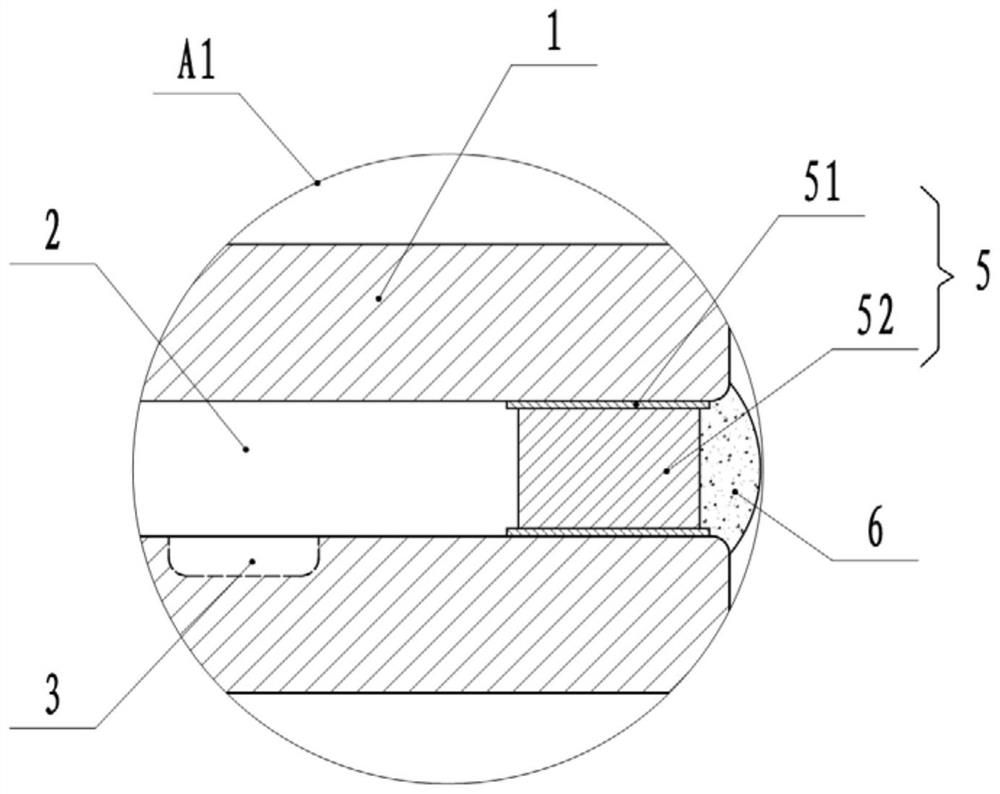

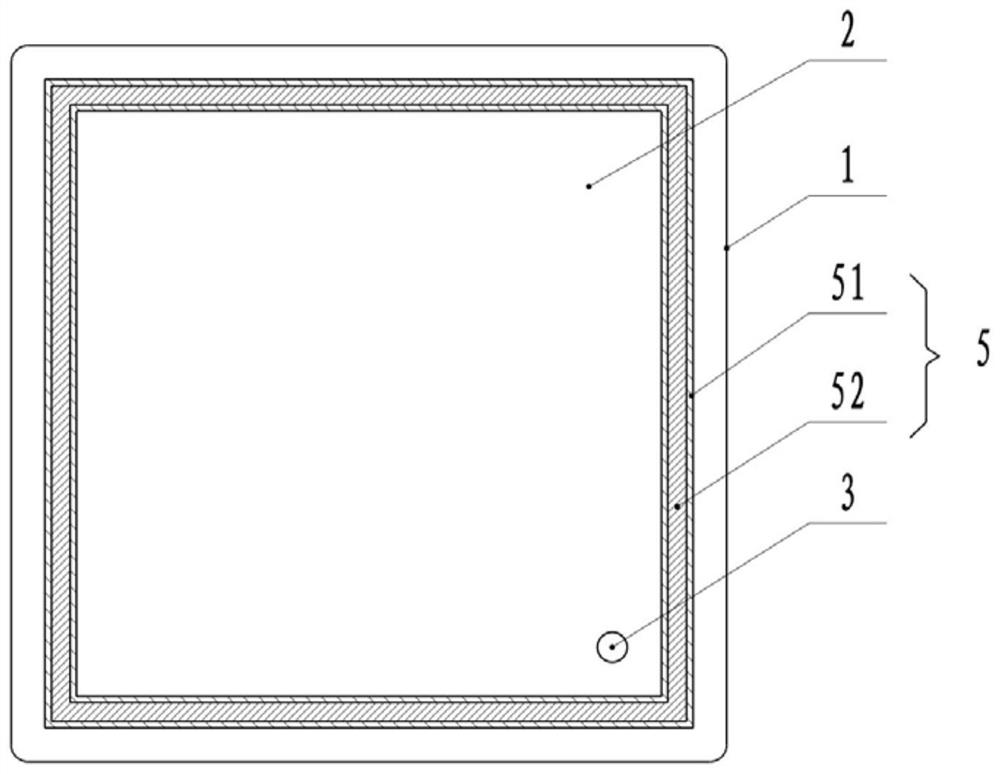

[0049] This embodiment is basically as Figure 1-3 As shown, a fully tempered vacuum glass includes two glass plates 1, a sealing structure is arranged between the two glass plates 1, and a vacuum chamber 2 is formed between the glass plates 1 and the sealing structure.

[0050] A blind hole 3 is arranged on the inner side of one of the glass plates 1, and the blind hole 3 is arranged on the two sides of the glass plate 1 at an equidistant distance of 15-25mm in the region. The diameter of the blind hole 3 is 12mm, and the depth of the blind hole 3 It is 30% of the thickness of the glass plate 1, and a getter (not shown in the figure) is placed in the blind hole 3 . A plurality of support columns 4 are arranged in the vacuum chamber 2 , the distance between adjacent support columns 4 is 50 mm, and the two ends of the support columns 4 are offset against two glass plates 1 respectively.

[0051] The sealing structure is arranged around the two glass plates 1 near the edge area...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 is that in this embodiment, the coating and curing of the metal paste and the coating and curing of the solder paste are carried out on the corresponding surfaces of the glass plates A / B, using two different A slurry of ingredients is made. Thus, the process of distributing solid solder strips on the alloy paste coating area is subtracted.

[0066] Coat the metal paste once in the peripheral area around the glass plate A and glass plate B, and then coat a layer of solder paste in the coating area of the metal paste. The coating width of the solder paste is 8mm, and the solder The coating area of the paste had a glass edge of 3 mm, and the coating thickness of the solder paste was 0.5 mm. After the solder paste coating is completed, it is cured by infrared heating. The remaining steps are the same as in Embodiment 1.

Embodiment 3

[0068] The difference between this embodiment and the first embodiment is that in this embodiment, the sintering temperature is 670°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com