Concrete cast-in-place pile bottom sediment thickness detection device and method

A sediment thickness and detection device technology, applied in the direction of measuring device, mechanical thickness measurement, mechanical measuring device, etc., can solve the problems of inconvenient shaft fixing, affecting detection, and single function, so as to save driving energy, improve cleaning effect, and function Variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

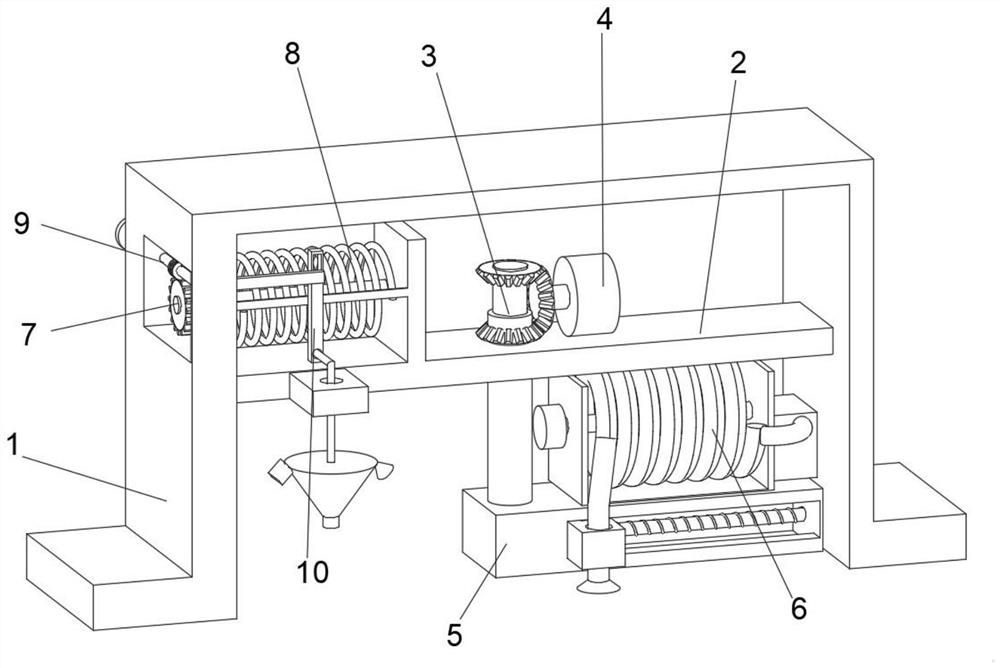

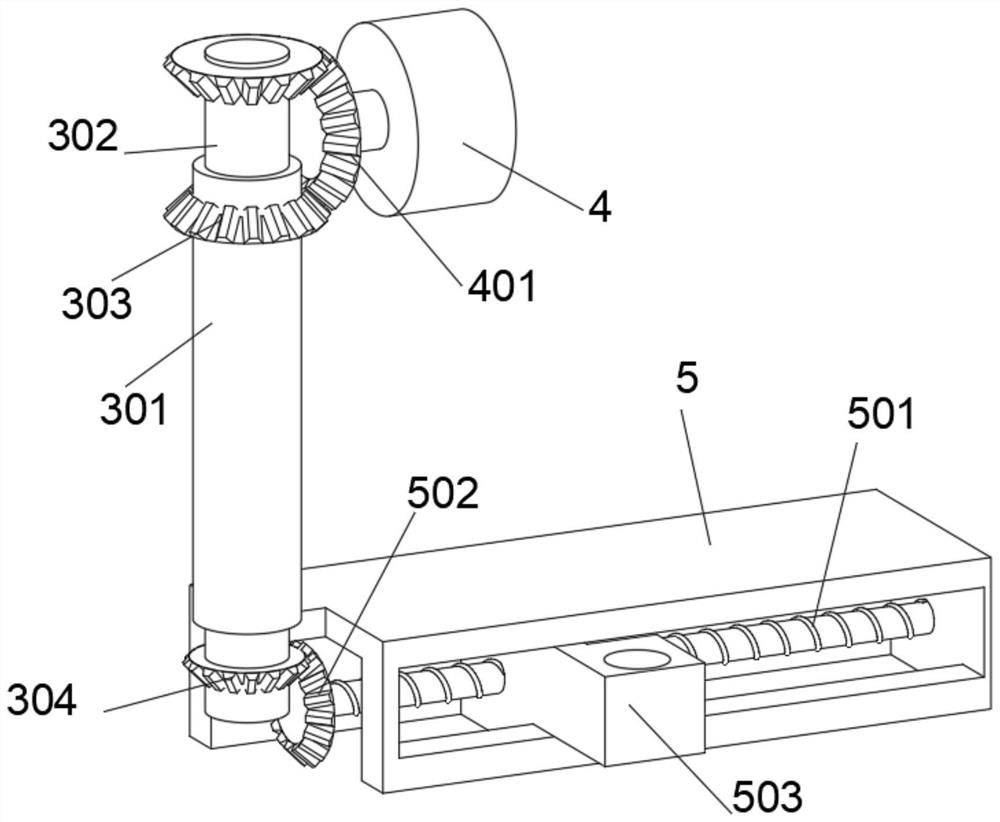

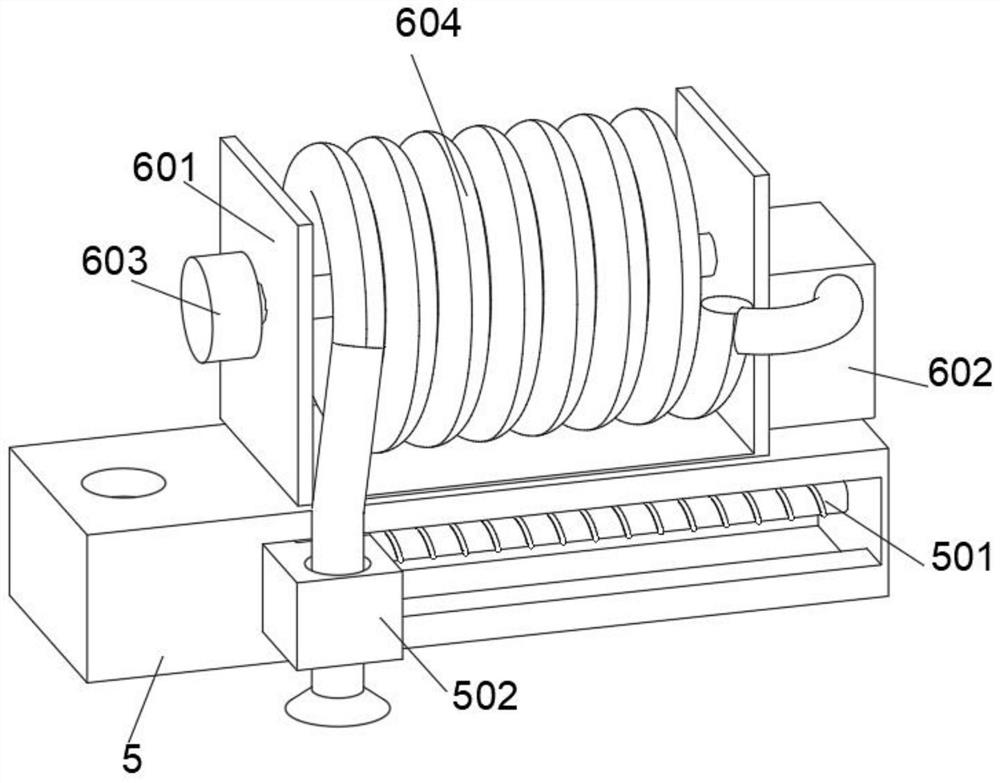

[0028] Please refer to Fig. 1-4, the present invention provides a kind of technical scheme:

[0029] A device for detecting the thickness of sediment at the bottom of a concrete pouring pile, comprising a fixed frame 1, a fixed plate 2 is connected to the inner wall of the middle part of the fixed frame 1, and a transmission assembly 3 is connected to the top surface of the middle part of the fixed plate 2 through rotation, and the transmission assembly 3 3 includes a sleeve 301, the lower end of which passes through the top surface of the fixed plate 2 and extends to the lower part and is connected and fixed with the top surface of the rotating plate 5. The upper end of the 302 and the outer wall of the upper end of the casing 301 are both sleeved with a bevel gear B303, the bevel gear B303 is engaged with the bevel gear A401 sleeved on the outer wall of the output end of the motor A4, and the outer wall of the lower end of the sleeve rod 302 passes through the top of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com