Load-sensitive control hydraulic system

A technology of load sensitive control and hydraulic system, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of increasing energy consumption, increasing installation space, and increasing costs, so as to save costs and improve Effects of Space Utilization and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

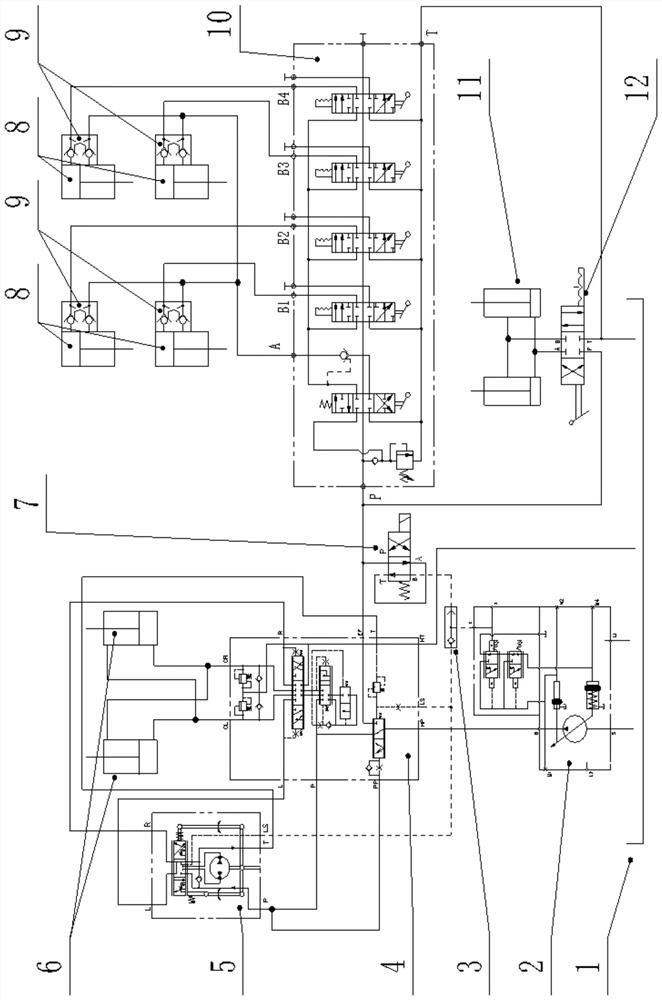

[0018] like figure 1 As shown, a load-sensitive control hydraulic system of the present invention includes a hydraulic oil tank 1, a load-sensitive pump 2, a shuttle valve 3, a flow amplifier 4, a steering gear 5, two steering cylinders 6 and a solenoid valve 7, and a load-sensitive pump 2 The S port is fed from the hydraulic oil tank 1, and the B port of the load-sensing pump 2 is connected to the HP port of the flow amplifier 4. The flow amplifier 4 and the steering gear 5 have correspondingly connected P port, T port, R port, L port and Ls port , the flow amplifier 4 is also provided with a CL port and a CR port which are inversely paralleled with the two steering cylinders 6, the EF port of the flow amplifier 4 is connected to the P port of the solenoid valve 7, and the flow amplifier 4 is also provided with a return oil to the hydraulic oil tank 1 The HT port of the shuttle valve 3 is connected to the Ls port of the flow amplifier 4 and the B port of the solenoid valve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com