Buffer base coaxiality assembling and adjusting test tool, assembling and adjusting test method as well as verification and testing method

A technology for testing tooling and coaxiality, which is applied to measuring devices, mechanical measuring devices, and mechanical devices, etc. It can solve the problems of large jumping error of display table data, many changes of coaxiality, and heavy workload of operators. , to achieve the effect of saving adjustment man-hours, improving production efficiency, and avoiding repeated adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than limiting.

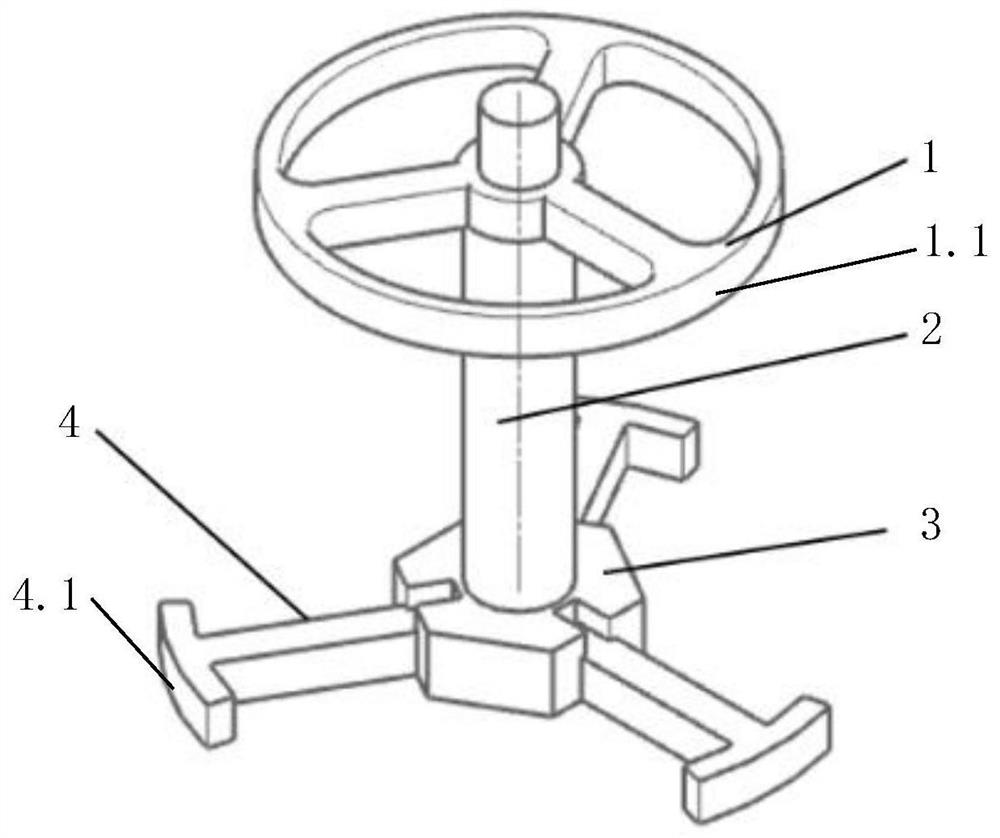

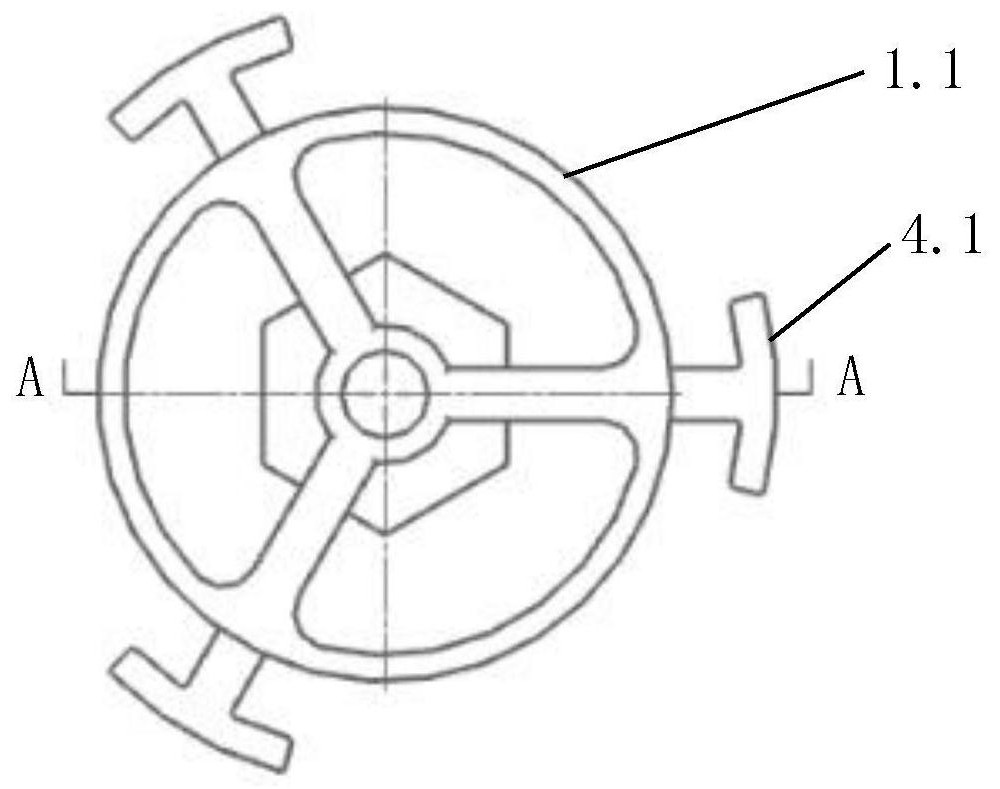

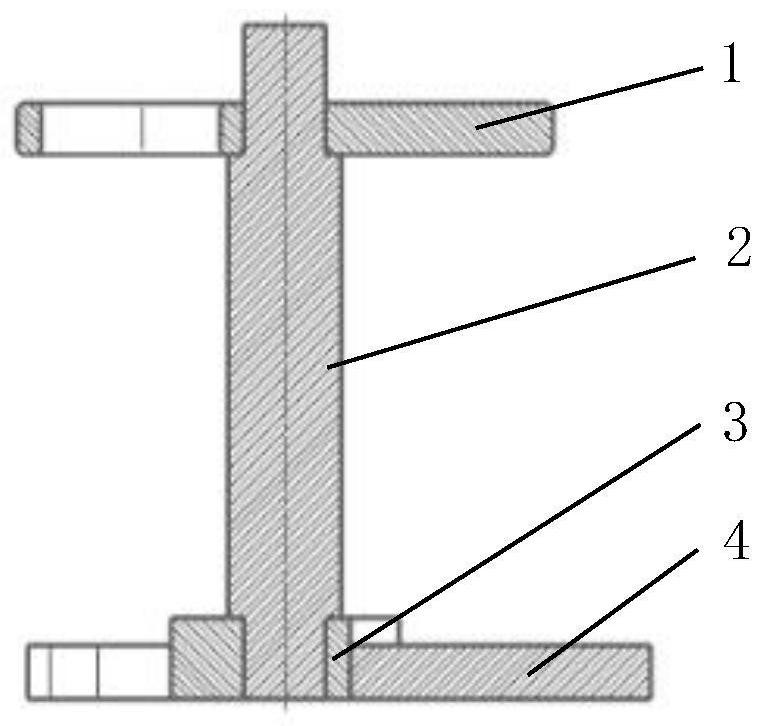

[0034] A buffer base coaxiality adjustment test tool, please refer to Figure 1-5 , mainly including: base coaxial bottom bracket 3, base coaxial positioning part 4, upper mounting plate coaxial positioning part 1, coaxial guide rod 2;

[0035] The specific structures and functions of the above components are as follows:

[0036] 1. Base coaxial bottom bracket: fix the position of the coaxial positioning part of the base and support the positioning of the coaxial guide rod. Its shape is a flat column, which can be a flat cylinder, a positive multi-deformation flat cylinder, etc. A central positioning hole is vertically arranged on the coaxial bottom bracket of the base, and the outer part of the coaxial positioning part of the base is formed by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com