High-precision medium-thickness plate width measuring method based on machine vision

A width measurement and machine vision technology, applied in measurement devices, instruments, genetic models, etc., can solve the problems of not taking into account the small angle deviation of the camera, unable to adapt to steel plate width detection, limited camera accuracy, etc., to achieve extended accuracy and detection range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0036] The invention provides a machine vision-based method for measuring the width of a medium-thick plate with high precision.

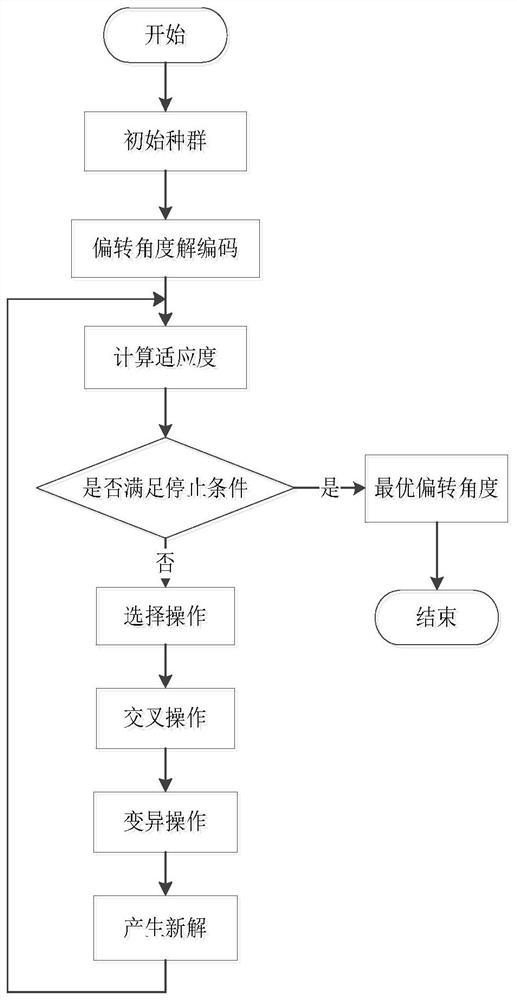

[0037] like figure 1 As shown, the method includes the following steps:

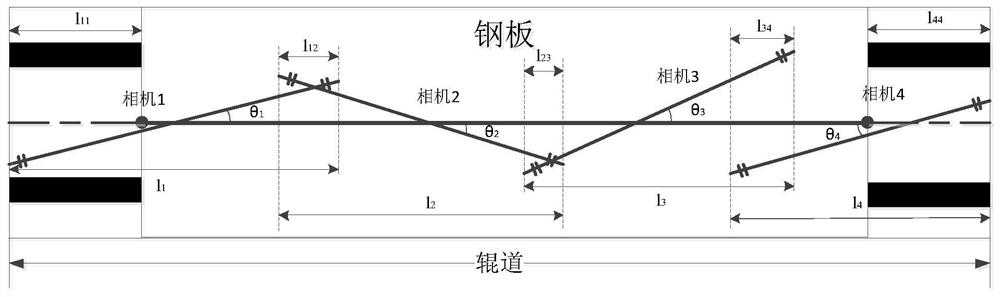

[0038] (1) Multiple line array cameras are distributed along the width direction of the steel plate on the same horizontal line to collect images of the lower surface of the steel plate, and the shooting range of each camera overlaps to a certain extent;

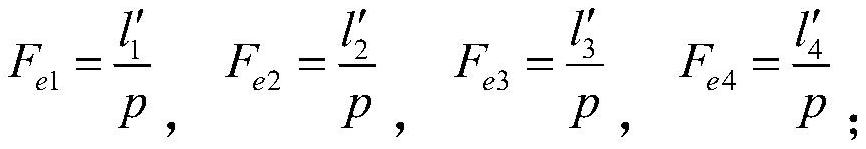

[0039] (2) According to the data calibrated by the cameras, remove the overlapping pixels of the shooting areas between the cameras;

[0040] (3) Segment the pixels representing the steel plate in each camera image, and combine the actual resolution of the camera to obtain the actual steel plate range...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap