High-speed rail ballastless track bearing platform three-dimensional shape detection method based on digital image

A technology of digital image and three-dimensional shape, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as difficult to meet, long measurement process time, and less information, and achieve high measurement efficiency, short measurement time, and easy The effect of accurate implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

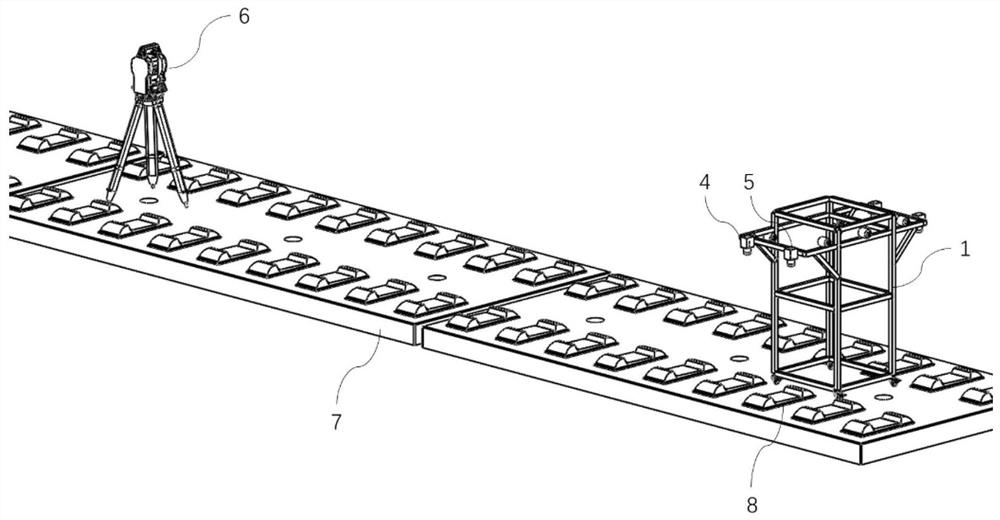

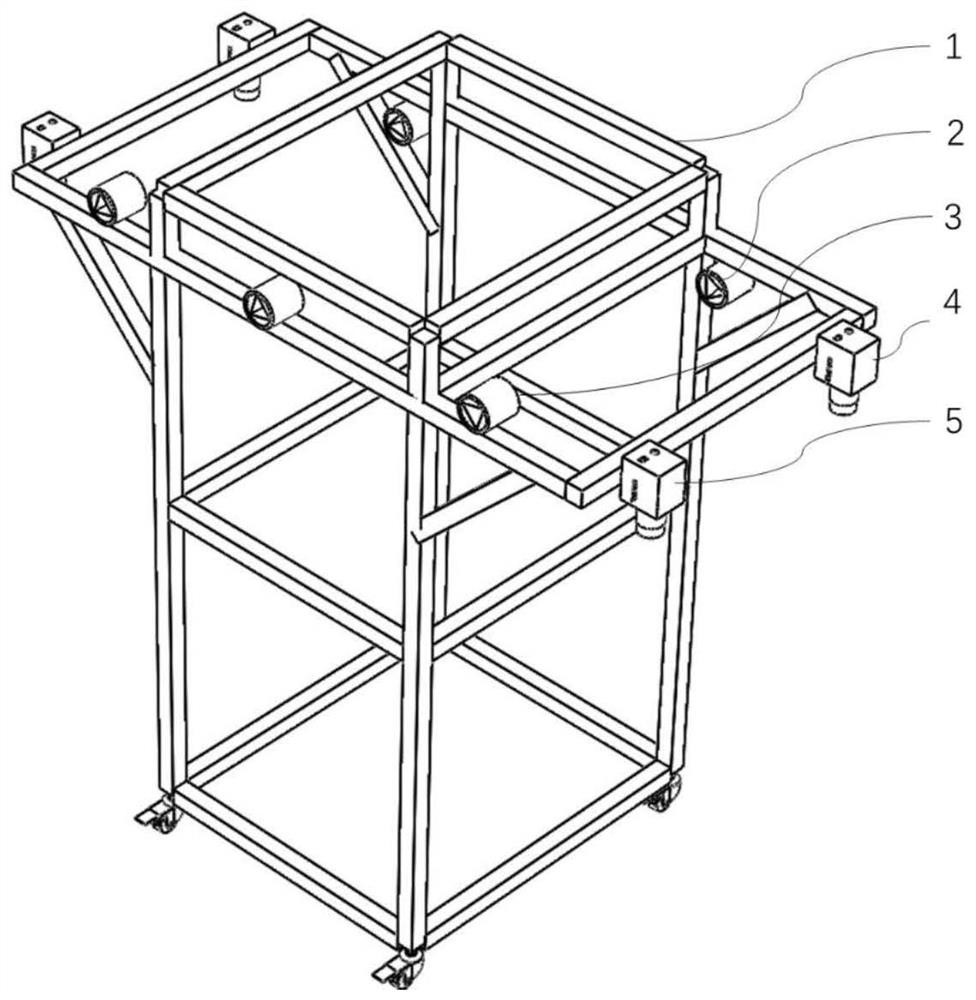

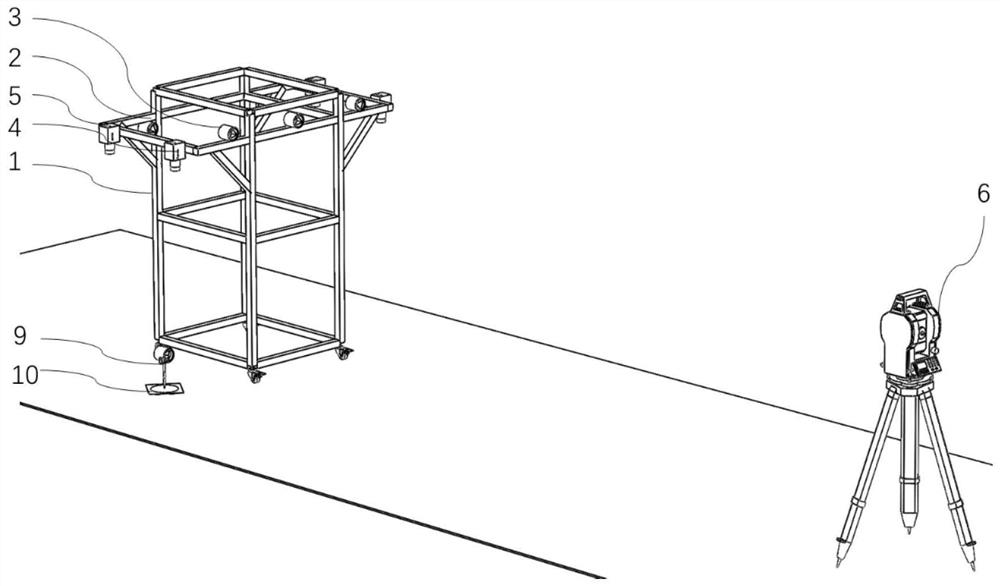

[0044] see figure 1 , figure 2 and image 3 , in order to realize the three-dimensional shape detection of high-speed rail track platform based on digital images, the detection system is set up, including a binocular vision camera and a total station prism measurement unit; among them, the binocular vision camera is composed of two cameras, which are respectively the first A camera 4 and a second camera 5, the two cameras are fixedly installed on the same height position of the detection frame 1, and are respectively located on the left and right sides of the detection frame 1; in specific implementation, the binocular vision camera consists of two industrial Composed of cameras and supporting lenses, the camera model is Hikvision MV-CH089-10UM, with a resolution of 4096×2160 pixels and an aspect ratio of 16:9, which is close to the shape of a single rail platform; the lens matched with the industrial camera is Hikvision Convision MVL-KF2528M-12MP, 25mm fixed-focus lens, ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com