Freezing replacement blending instrument

A technology of mixers and components, which is applied in the field of freezer substitution system equipment, can solve the problems of affecting experimental efficiency, time-consuming and laborious sample preparation, and frostbite of experimenters' fingers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

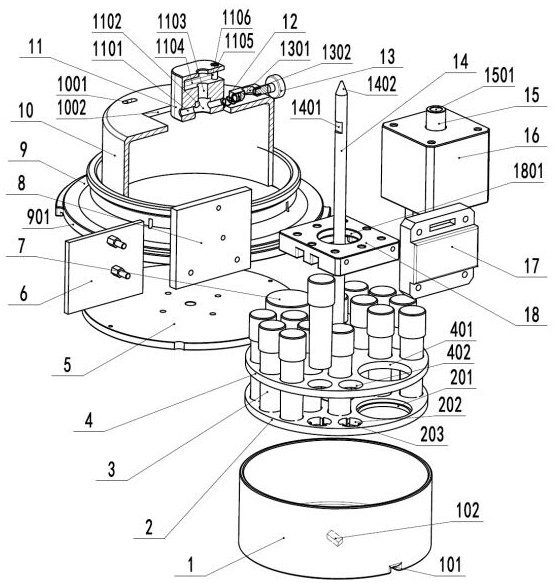

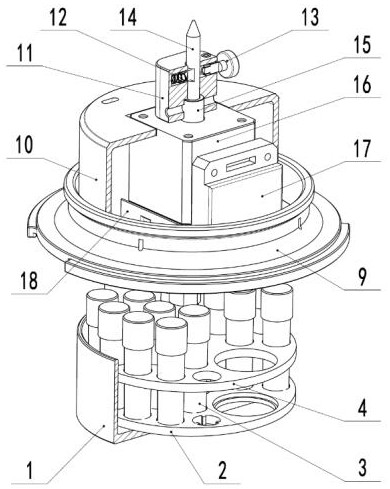

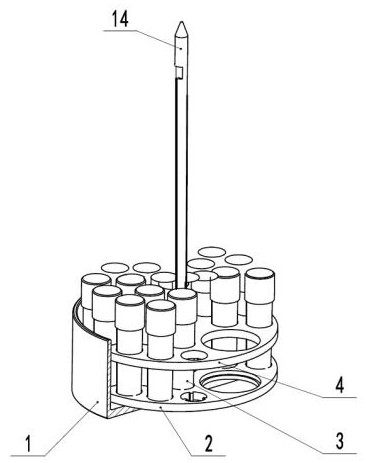

[0026] Freezing Substitution Mixer mainly includes sample installation components, quick release components, rotation components and intelligent control components.

[0027] The sample installation assembly includes a liquid tank 1, a bottom bracket 2, a holder 4, and a fixed shaft 14; the liquid tank 1 is set in the low-temperature tank of the refrigeration substitution equipment, and the bottom bracket 2 and the holder 4 are arranged in parallel, and fixed The shaft 14 is connected as a whole and cooperates with the liquid tank 1, that is, the whole can freely rotate around the liquid tank 1 or move axially, which is convenient for sample preparation and disassembly; the bottom of the liquid tank 1 is provided with a first groove 101, The second groove 102, the liquid tank 1 is detachably arranged in the low temperature tank of the refrigeration substitution equipment through the first groove 101, preventing it from rotating around the low temperature tank. When the sample m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com