Method and device for producing a filter for tobacco products

A technology for tobacco products and filter tips, which is applied in the field of manufacturing filter tips for tobacco products, can solve problems such as excessive mass production requirements, and achieve the effect of high insensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

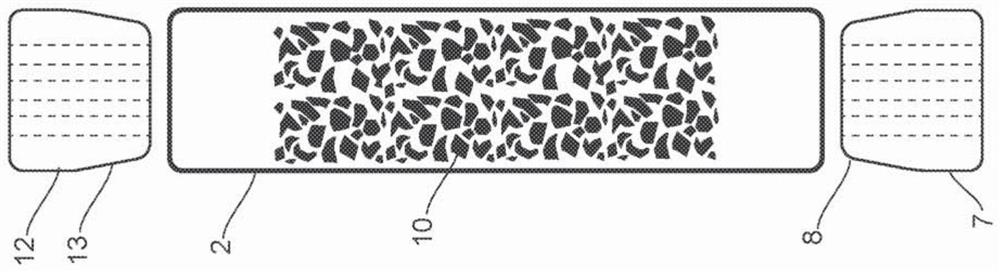

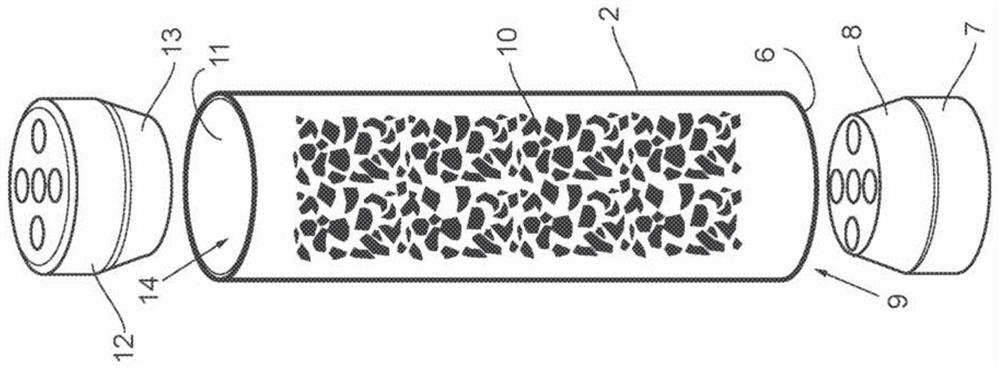

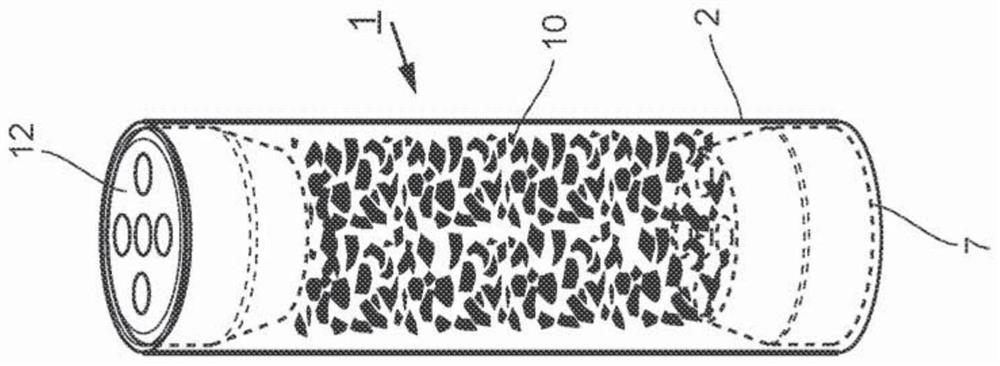

[0029] exist figure 1 The filter 1 for tobacco products is shown as an exploded view in isometric side view. The filter 1 consists of a paper or cardboard tube 2 which is closed at its open ends by a ceramic screen 7 and 12 in each case. In the exploded view, the ceramic screens 7 and 12 having a cork-like structure are shown remote from the paper or cardboard tube 2 . The ceramic sieves 7 and 12 have frustoconical tips 8 and 13 which simplify the insertion of the corresponding ceramic sieves 7 and 12 into the open ends 9 and 1 of the paper or cardboard cylinder 2 with a press fit. 14 in. Granular activated carbon is present in the paper or cardboard tube 2 , which removes undesired smoke by-products from the smoke by adsorption.

[0030] exist figure 2 shown in figure 1 The perspective view of the filter in , wherein the ceramic sieves 7 and 12 are also shown away from the paper tube or cardboard tube according to the exploded view. Ceramic sieves 7 and 12 are inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com