Stock solution oil tea production device and production process capable of automatically blending materials

A production device and technology of camellia oleifera, which is applied in tea, tea extraction, tea treatment before extraction, etc., can solve the problems of inconvenient and fast slag discharge, low production efficiency, limited production capacity, etc., achieve good beating effect, improve processing effect, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

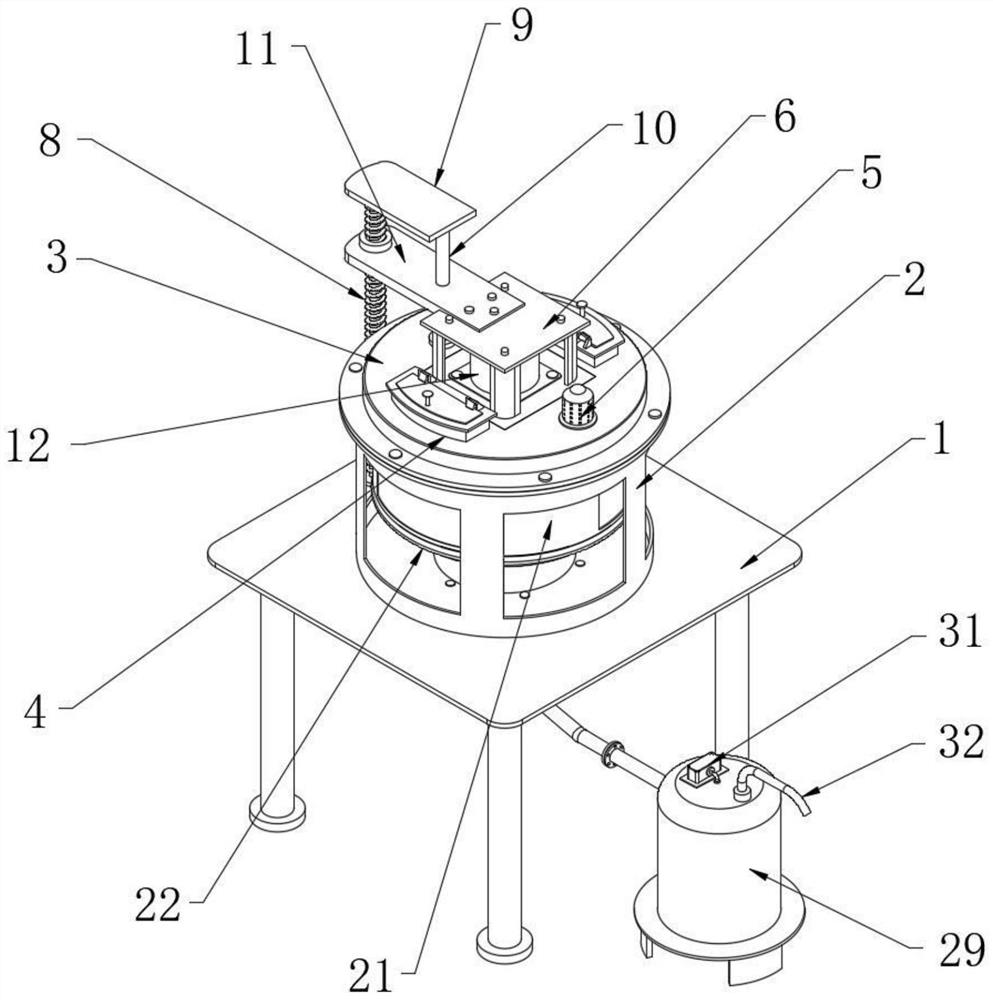

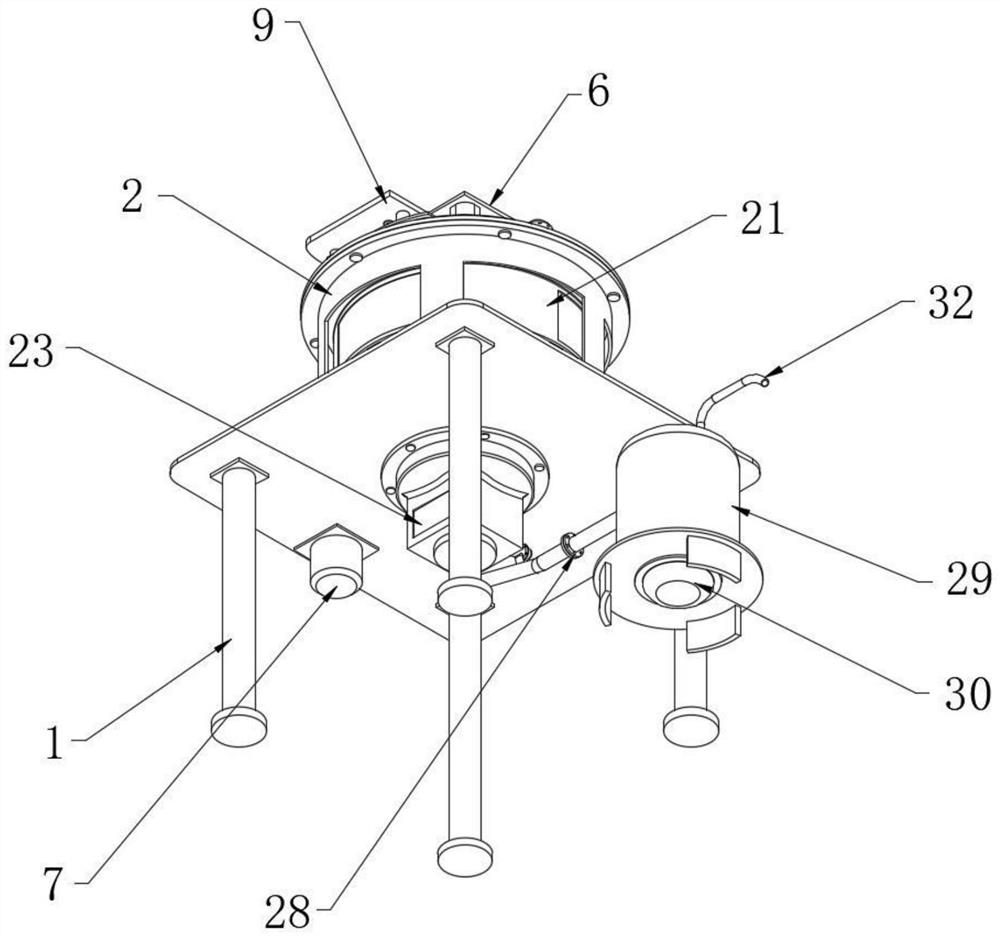

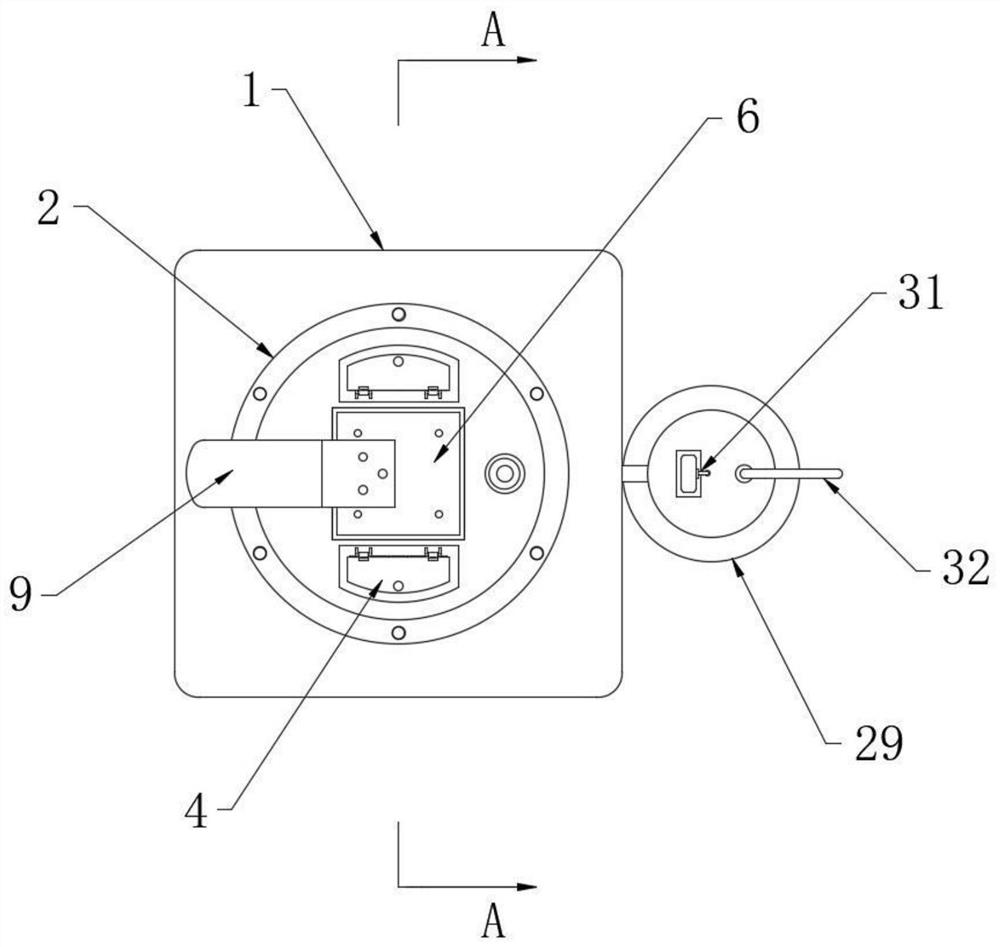

[0036] Please refer to Figure 1 to Figure 7 Shown, it has shown the specific structure of the preferred embodiment of the present invention, a kind of stock solution camellia oleifera production device that automatically mixes ingredients, comprises base 1 and liquid storage tank 29, and the top of described base 1 is equipped with top shell 2 , and the top shell 2 is a hollow structure; the top of the top shell 2 is equipped with a top cover 3, and the bottom of the top cover 3 is installed with an inner shell 21, and is located inside the top shell 2; the top cover 3 The top is provided with feed inlet 4, and feed inlet 4 is symmetrically arranged with two about the axis line of top cover 3, and the top side of top cover 3 is installed simultaneously; The top of described top cover 3 is installed with The movable frame 6, and the bottom of the movable frame 6 is connected with the top of the top cover 3 in an inlaid connection; the bottom side of the base 1 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com