Punching equipment for metal toothpick box cover

A box cover and toothpick technology, which is applied in metal processing equipment, pushing equipment, grinding/polishing equipment, etc., can solve the problems of reducing work efficiency, requiring a lot of effort, and the surface of the toothpick box cover is hard, so as to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

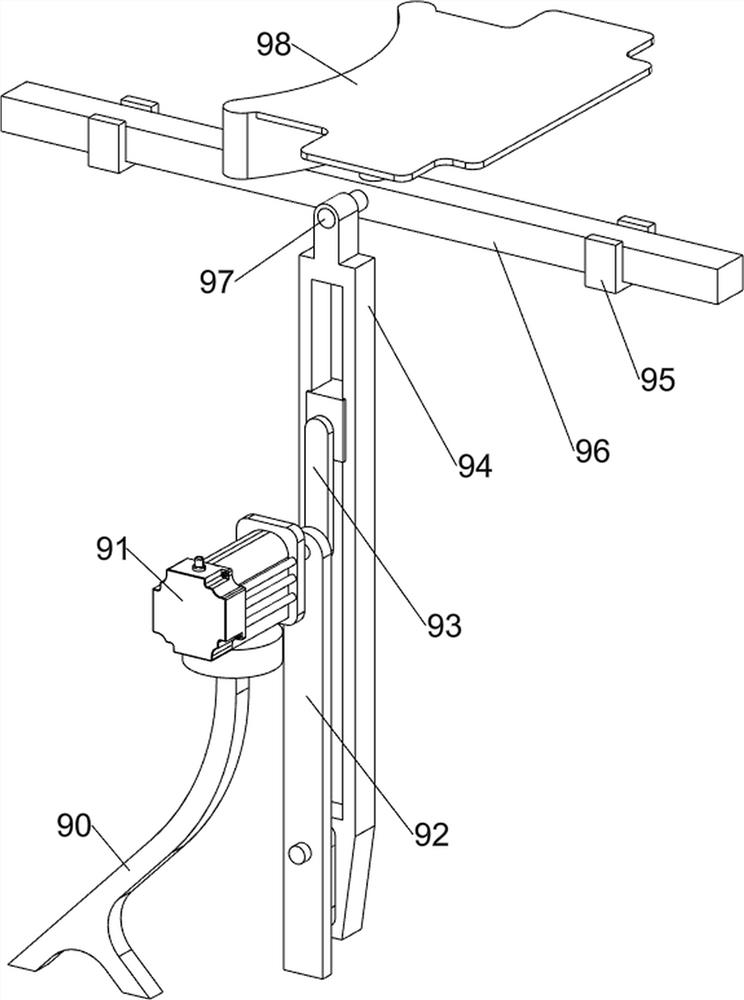

[0026] Toothpick metal punching apparatus for cover, such as Figure 1-3 Shown, comprises a bottom plate 1, frame 2 is placed, the mounting plate 3, the first bracket 4, a cylinder 5, the punch 6, the tool 7, 8 and the waste collection mechanism pusher mechanism 9, the base plate 1 is connected to frame 2 are placed, is placed 2 is connected to the top frame mounting plate 3, a top plate 3 is provided with a first mounting bracket 4, the bracket 4 is provided on the first cylinder 5, the cylinder 5 is provided with a bottom punch 6, a bottom tool 6 is provided with the right punch 7, a base plate, the mounting plate is provided between the waste collection means 78 and the tool 3, the ejector mechanism 9 is provided between a right side plate 3 and the mounting plate.

[0027] Waste collection mechanism 8 comprises a fixed block 80, a first spring 81, the mounting block 82, the slide plate 83 and collection tank 84, the left side of the base plate 1 is provided with the collecting ...

Embodiment 2

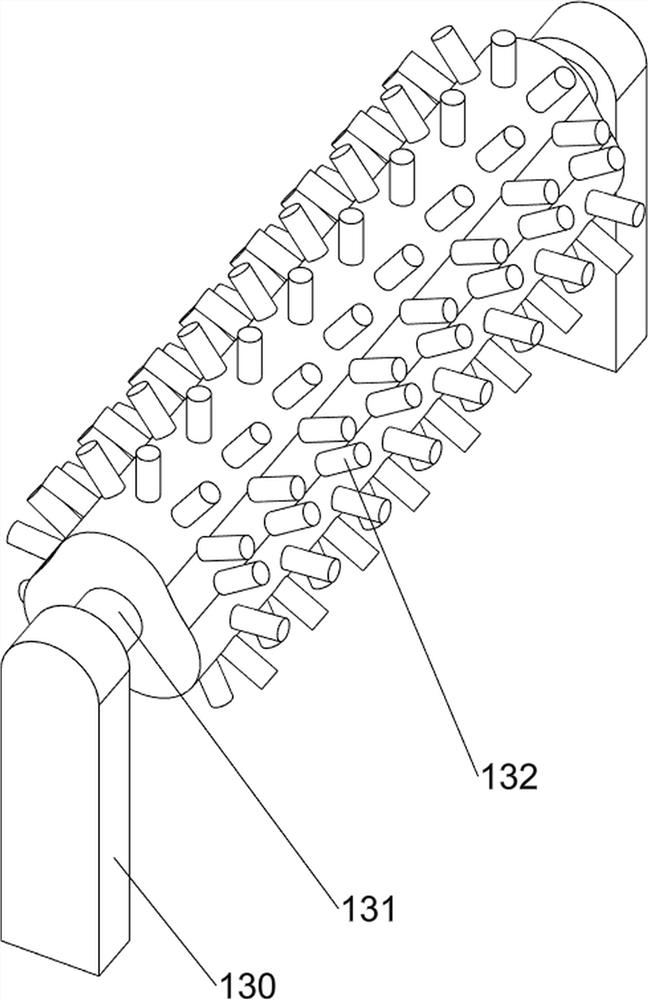

[0031] On the basis of Example 1, such as Figure 4-8 As shown in further comprising feeding mechanism 10, feeding mechanism 10 comprises a guide plate 100, the arcuate plate 101 and the hollowed hollow cylinder 102, the front and rear sides of the top mounting plate 3 are connected with a guide plate 100, the right guide plate 100 is connected between the hollow arcuate plate 101, top plate 101 is provided with an arcuate hollow cylinder 102 hollow.

[0032] When people need feeding, toothpick cover may be placed within the hollow arcuate plate 101, so that the drive interval toothpick cover Ejector 98 is moved left and right to the left, the guide plate 100 acts as a guide.

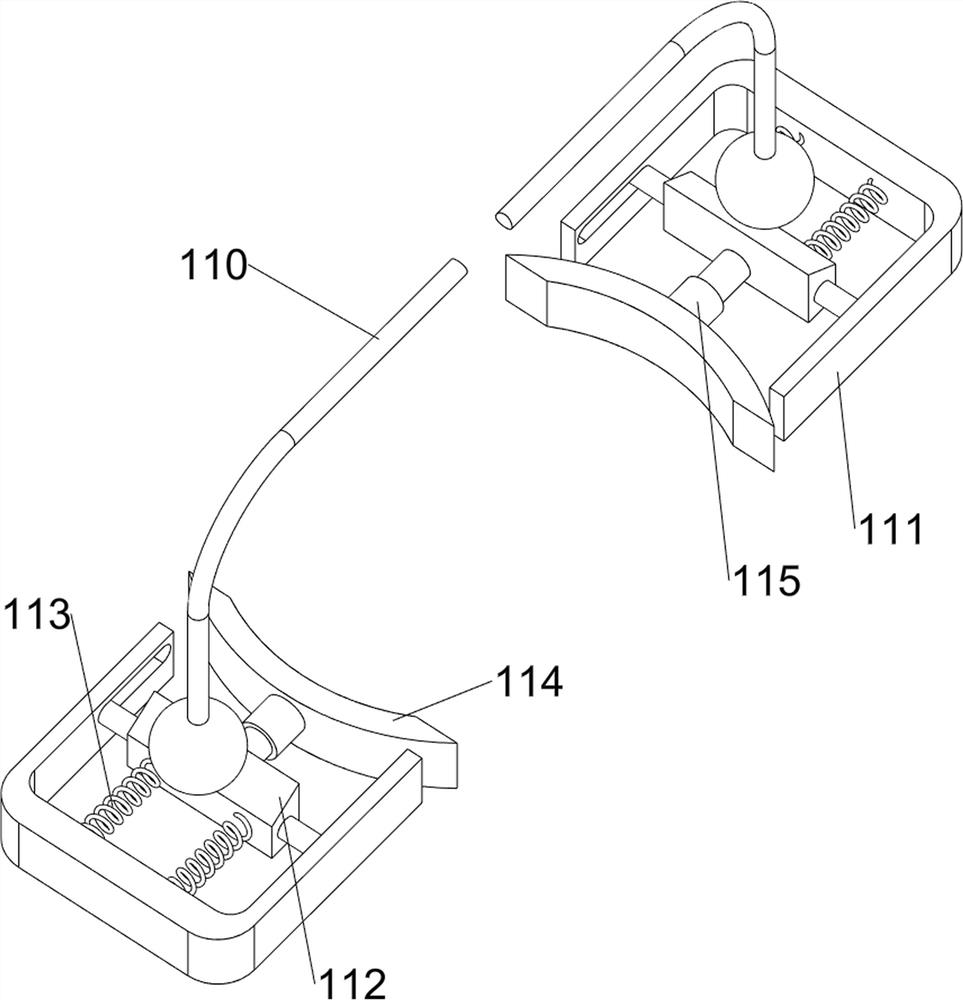

[0033] 3 further comprises a finite bit intermediate mechanism 11, the stopper mechanism 11 comprises a lever 110, a first slide rail 111, wedge 112, a second spring 113, a rubber plate 114, sleeve 115 and a third spring 116, mounting plate top front and top sides are connected with a first slide rail 111 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com