Corn husk stripping equipment for agriculture

A technology for stripping equipment and corn, applied in agricultural machinery and equipment, agriculture, threshing equipment, etc., can solve the problems of time-consuming and laborious, and achieve the effect of improving work efficiency and facilitating collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

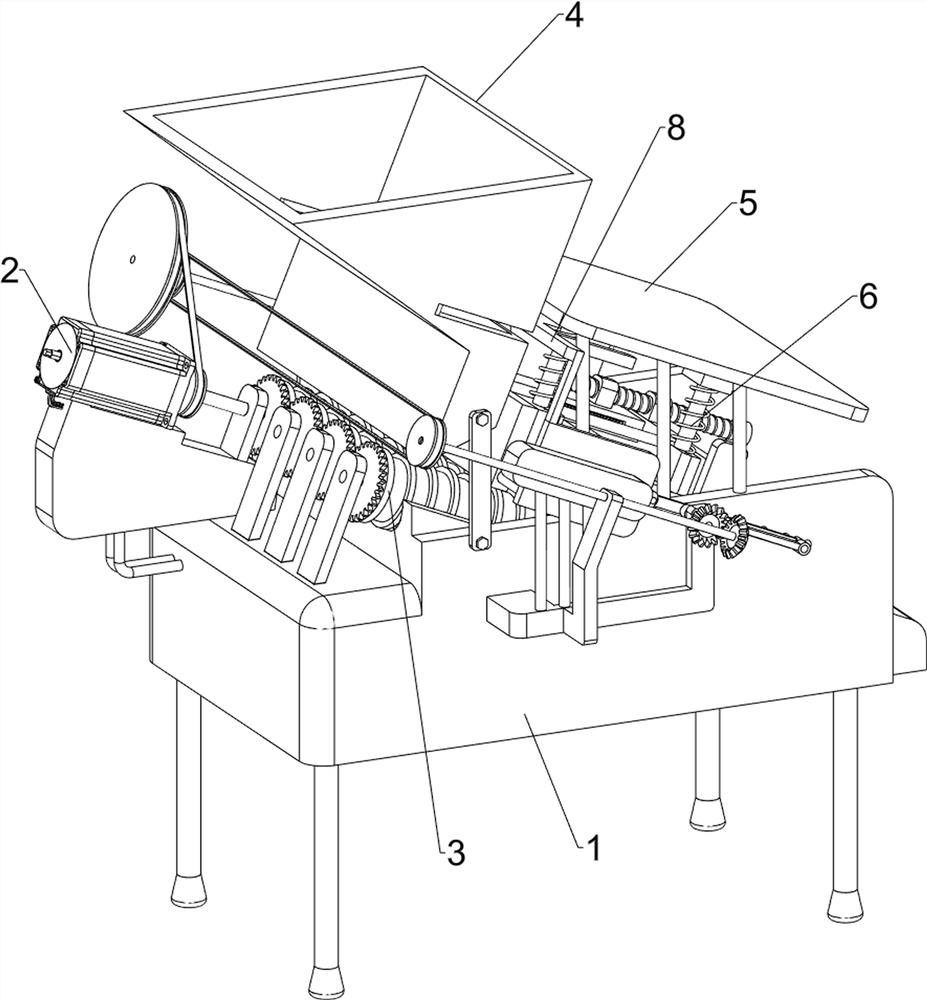

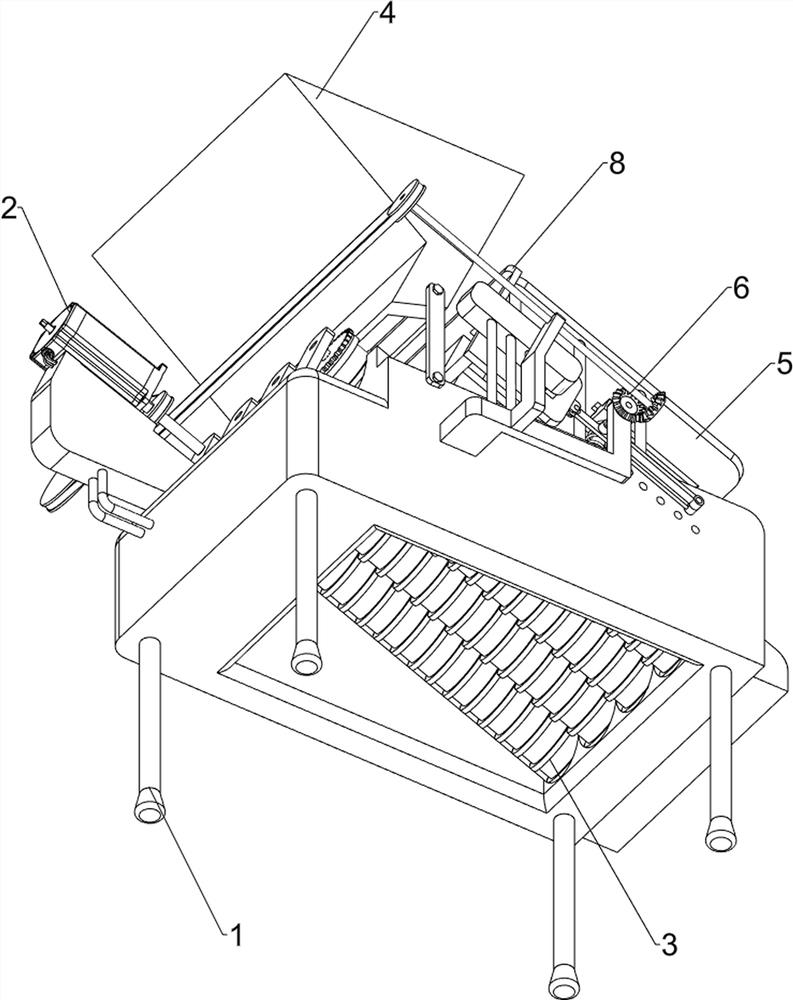

[0049] A kind of agricultural corn peeling equipment, such as Figure 1-3 As shown, it includes a material holding box 1, a servo motor 2, a peeling mechanism 3, a material lowering box 4, a first mounting plate 5 and an intermittent feeding mechanism 6, the left side of the material holding box 1 is provided with a servo motor 2, and the servo motor 2 A peeling mechanism 3 is connected between the output shaft and the material box 1, a lower material box 4 is connected between the front and rear sides of the left part of the material box 1, a first mounting plate 5 is connected to the top of the right side of the material box 1, and the peeling mechanism 3 and the material box 1 are connected with an intermittent feeding mechanism 6 .

[0050] When people need to peel the corn, the corn is first placed in the feeding box 4, the corn falls into the peeling mechanism 3, people start the servo motor 2, and the output shaft of the servo motor 2 rotates to drive the intermittent f...

Embodiment 2

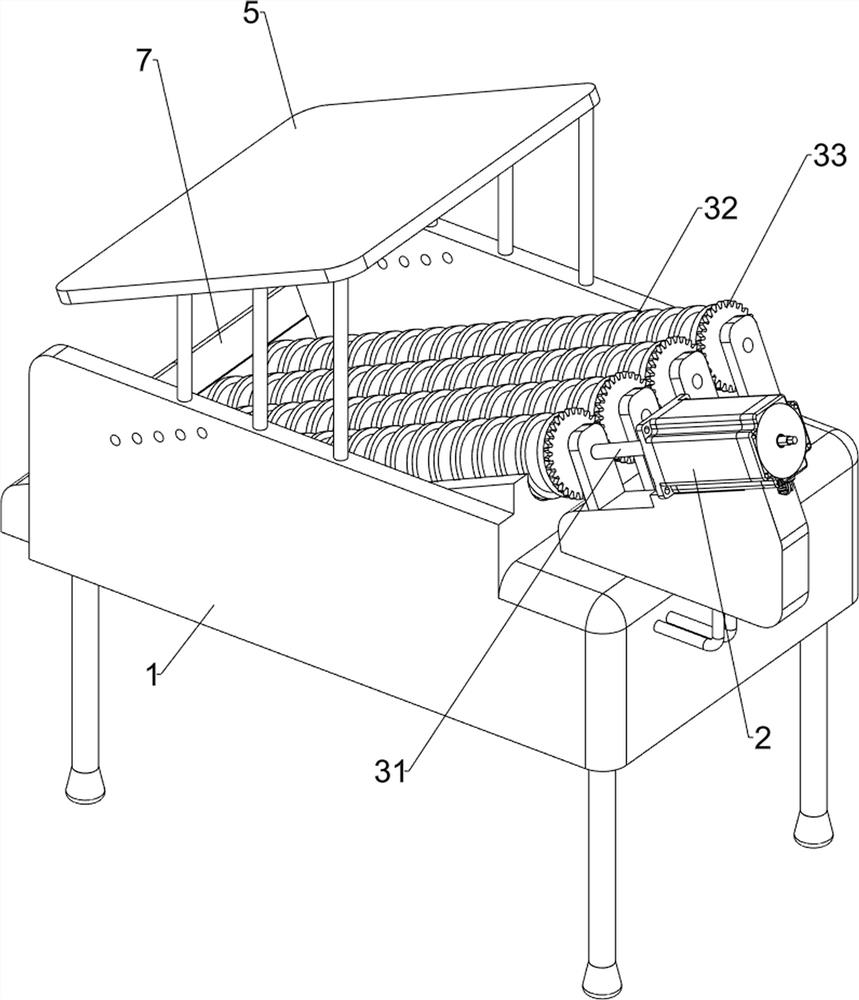

[0052] On the basis of Example 1, such as Figure 4-5 As shown, the stripping mechanism 3 includes a first rotating shaft 31, a cylinder 32 and a spur gear 33, the output shaft of the servo motor 2 is connected with the first rotating shaft 31, and the first rotating shaft 31 passes through the material box 1, and the left and right sides of the material box 1 Evenly rotating between the sides is connected with a cylinder 32, the left part of the cylinder 32 on the rear side is connected with the first rotating shaft 31, and the left side of the cylinder 32 is connected with a spur gear 33, and the spur gears 33 are meshed with each other.

[0053] When the corn falls on the drum 32, the servo motor 2 is started, and the output shaft of the servo motor 2 rotates to drive the first rotating shaft 31, the spur gear 33 and the drum 32 to continuously rotate, and the drum 32 is matched with the corn under the cooperation of the intermittent feeding mechanism 6. Carry out peeling, ...

Embodiment 3

[0055] On the basis of Example 2, such as Figure 4-6As shown, the intermittent feeding mechanism 6 includes a second shaft 61, a first transmission assembly 62, a second transmission assembly 63, a third shaft 64, a bevel gear set 65, a first connecting rod 66, a second connecting rod 67, a second Two mounting plates 68, first long plate 69, cover plate 610, second long plate 611, bearing seat 612, movable seat 613, screw mandrel 614, first elastic member 615, second elastic member 616, third elastic member 617 And the third mounting plate 618, the middle of the front and rear sides of the material box 1 is rotationally connected with the second rotating shaft 61, and the left side of the second rotating shaft 61 on the rear side is connected with the first transmission assembly 62 between the output shaft of the servo motor 2. A second transmission assembly 63 is connected between the left sides of the two rotating shafts 61, and a third rotating shaft 64 is rotatably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com