PVC glove production device

A technology for producing devices and gloves, which is applied to household components, household appliances, and other household appliances, etc., can solve problems such as box door hot accidents, floor mopping and wear, affecting the quality of PVC gloves, etc., and achieves the effect of avoiding hot hand accidents and avoiding wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

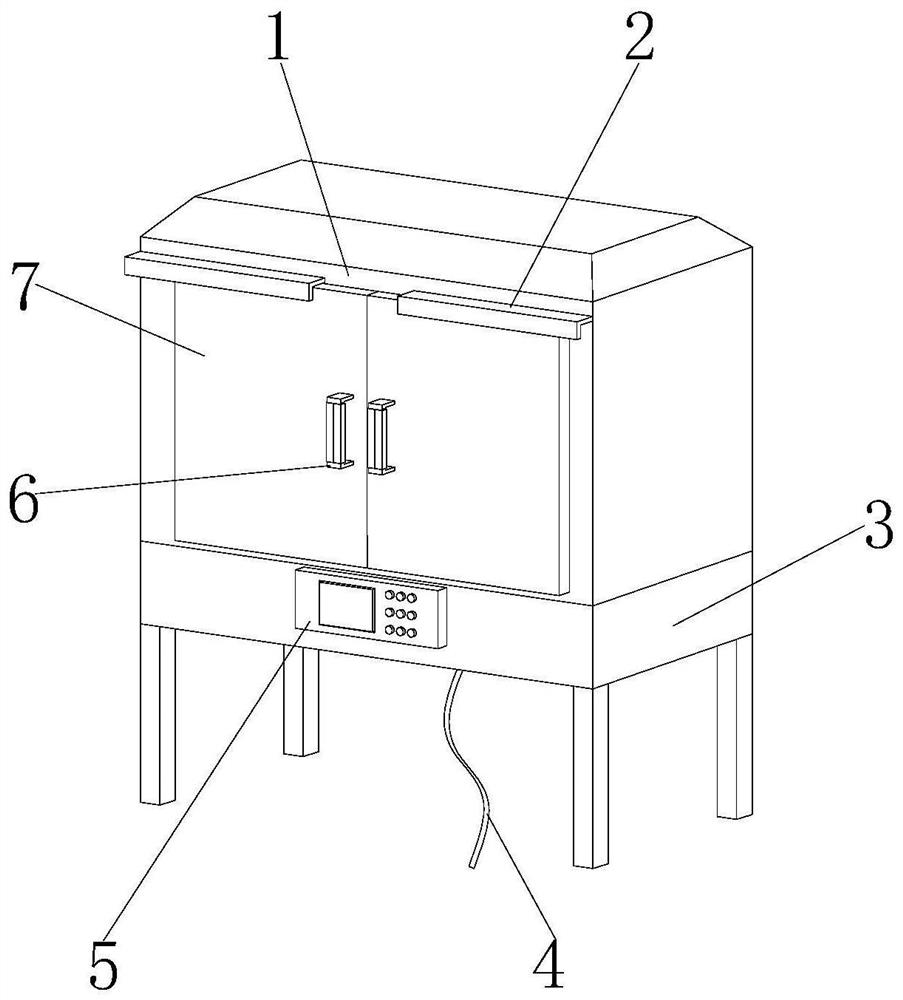

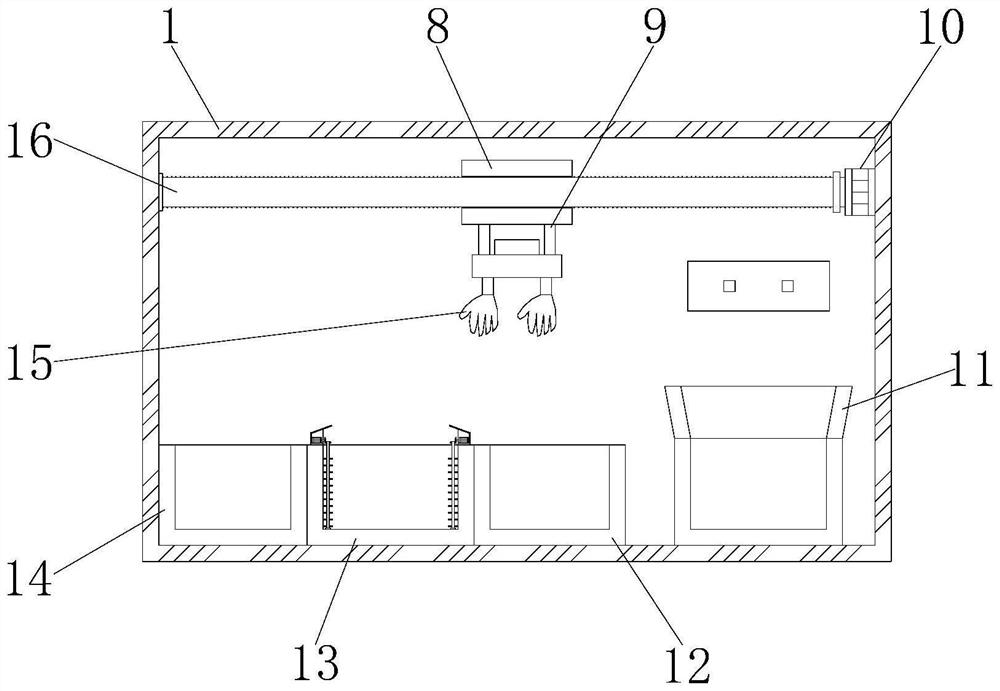

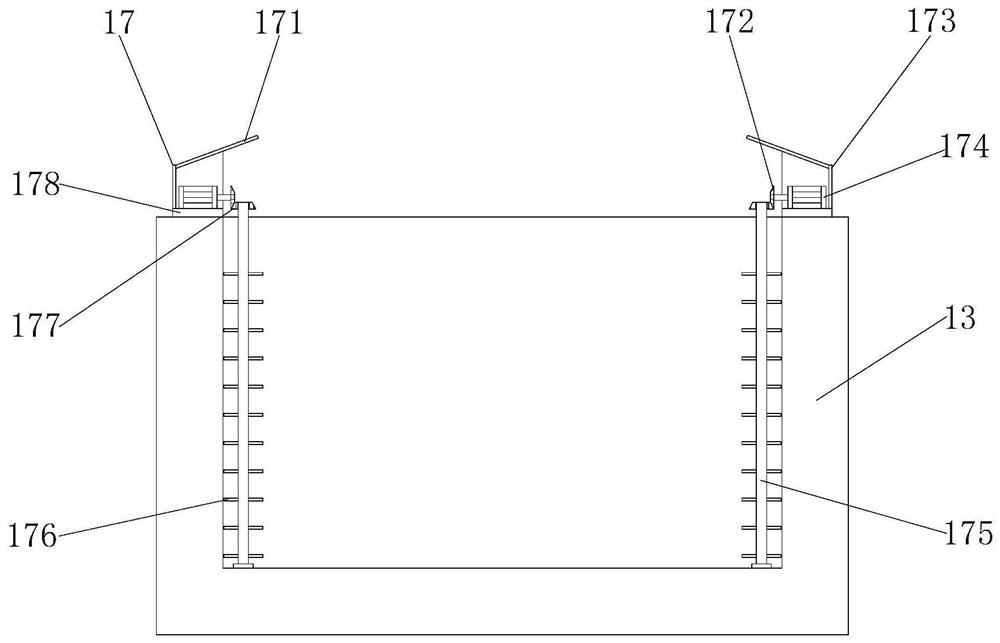

[0030] see Figure 1-9 , the present invention provides the following technical solutions: a PVC glove production device, including a base 3, a control panel 5 is connected to one side of the base 3, a power cord 4 is connected to the other side of the base 3, and a production host is arranged above the base 3 1. A slide rail 2 is arranged on the top of the production host 1, and a box door 7 is arranged inside the slide rail 2. A handle 6 is connected to the side wall of the box door 7. A motor 10 is connected to the inner wall of the production host 1. The motor 10 A threaded rod 16 is connected to the output end of the threaded rod 16. A threaded block 8 is arranged on the periphery of the threaded rod 16. The threaded block 8 is attached to the inner wall of the production host 1. A telescopic rod 9 is arranged under the threaded block 8. The telescopic rod 9 is far away from the threaded block. One end of 8 is connected with a hand mold 15, a fresh water tank 14 is provid...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that an anti-scald assembly 18 is provided on the periphery of the handle 6, and the anti-scald assembly 18 includes a heat insulation frame 183. The thermal frames 183 are bonded by glue,

[0037] Further in the present invention, the anti-scalding component 18 also includes heat-absorbing cotton 181 and a fixed sleeve 182, the periphery of the heat insulation frame 183 is provided with a fixed sleeve 182, and the side of the fixed sleeve 182 close to the heat-insulation frame 183 is connected with a heat-absorbing cotton 181 ,

[0038] By adopting the above technical solution, heat transfer to the fixing sleeve 182 is avoided.

[0039] Further in the present invention, the anti-scald component 18 also includes a groove 184, a connecting strip 185, a child Velcro 186 and a female Velcro 187, one end of the fixing sleeve 182 is provided with a groove 184, and the other end of the fixing sleeve 182 is connected ...

Embodiment 3

[0043] This embodiment differs from Embodiment 1 in that: specifically, a winding assembly 19 is provided on the side wall of the base 3 and above the power cord 4, and the winding assembly 19 includes an L-shaped rod 191, a fixing screw 192, a threaded The hole 193 and the fixed cylinder 194, the side wall of the base 3 and the top of the power cord 4 are connected with an L-shaped rod 191, the periphery of the L-shaped rod 191 is provided with a fixed cylinder 194, and both the L-shaped rod 191 and the fixed cylinder 194 are provided with There are threaded holes 193, and a fixed screw rod 192 is threadedly connected between the two threaded holes 193,

[0044] Further in the present invention, rubber pads are connected on the inner side wall of the fixed cylinder 194 and the outer side wall of the L-shaped rod 191, and the fixed cylinder 194 and the L-shaped rod 191 are bonded to the rubber pad by glue.

[0045] By adopting the above technical solution, friction between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com