Injection molding device based on mobile automatic rapid cooling and capable of avoiding excessive pressure intensity

A rapid cooling and pressure technology, applied in the field of plastic molding, can solve problems such as easy deformation of plastic models, and achieve the effect of avoiding easy deformation and avoiding excessive air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

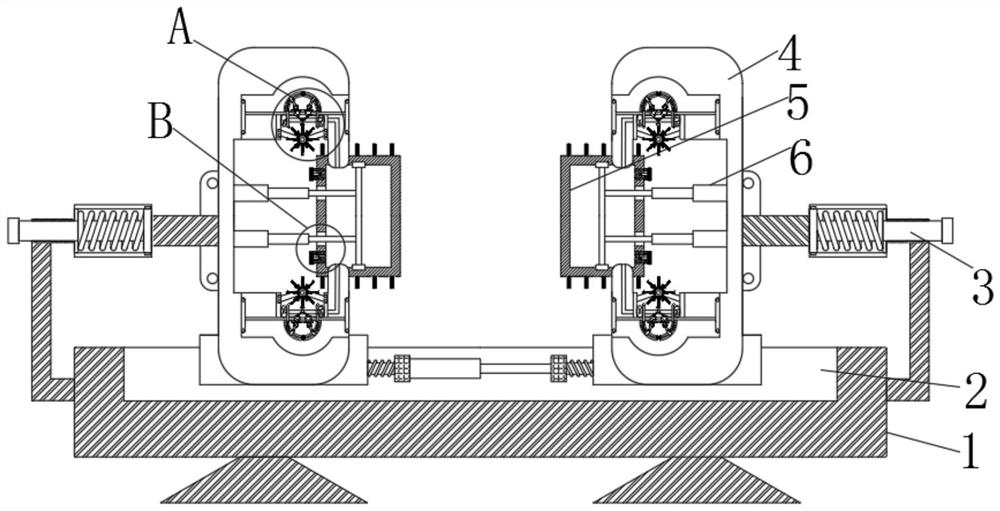

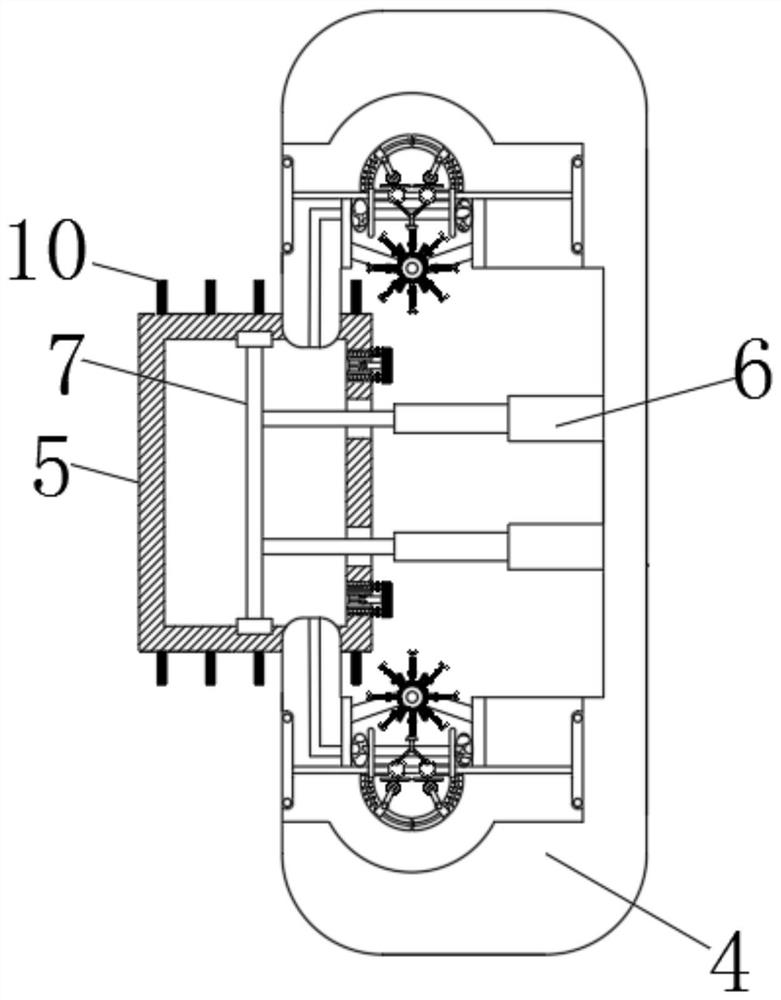

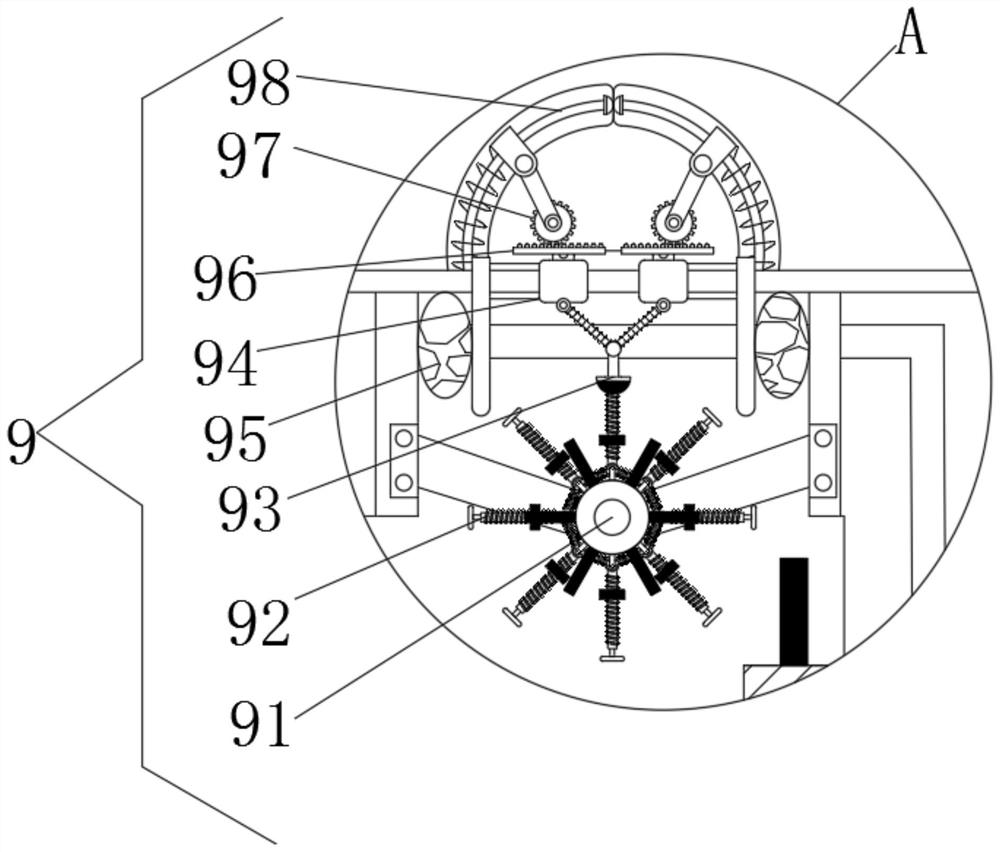

[0025] see Figure 1-3 , an injection molding device based on mobile automatic rapid cooling and avoiding excessive pressure, including a machine tool 1, a slide rail 2 is fixedly installed on the top of the machine tool 1, cushioning rods 3 are fixedly installed on the left and right sides of the machine tool 1, and the top of the slide rail 2 The left and right sides of the frame body 4 are slidably connected with a frame body 4, and the center of the frame body 4 is slidably installed with an injection cavity 5, and the side of the frame body 4 far away from the injection cavity 5 is fixedly installed with a telescopic rod 6, and the inside of the injection cavity 5 is slidably connected with a Injection molding plate 7, decompression device 8 is elastically installed on the outside of injection molding cavity 5, cooling device 9 is fixedly installed on the upper and lower sides inside frame body 4, cooling device 9 includes turntable 91, spring rod 92, compression rod 93, s...

Embodiment 2

[0027] see figure 1 , 2 and 4, an injection molding device based on mobile automatic rapid cooling and avoiding excessive pressure, including a machine tool 1, a slide rail 2 is fixedly installed on the top of the machine tool 1, and cushioning rods 3 are fixedly installed on the left and right sides of the machine tool 1, and the slide rails The left and right sides above 2 are slidably connected with the frame body 4, the center of the frame body 4 is slidably installed with the injection molding cavity 5, the side of the frame body 4 far away from the injection molding cavity 5 is fixedly installed with a telescopic rod 6, and the inside of the injection molding cavity 5 is slid An injection molding plate 7 is connected, and a decompression device 8 is installed elastically on the outside of the injection cavity 5. The decompression device 8 includes a magnetic block 81, a blocking block 82, an air valve 83, and an electromagnet 84. A blocking block is fixedly installed in ...

Embodiment 3

[0029] see Figure 1-4 , an injection molding device based on mobile automatic rapid cooling and avoiding excessive pressure, including a machine tool 1, a slide rail 2 is fixedly installed on the top of the machine tool 1, cushioning rods 3 are fixedly installed on the left and right sides of the machine tool 1, and the top of the slide rail 2 The left and right sides of the frame body 4 are slidably connected with a frame body 4, and the center of the frame body 4 is slidably installed with an injection cavity 5, and the side of the frame body 4 far away from the injection cavity 5 is fixedly installed with a telescopic rod 6, and the inside of the injection cavity 5 is slidably connected with a Injection molding plate 7, the outside of injection molding cavity 5 is elastically equipped with decompression device 8, and decompression device 8 comprises magnetic block 81, blocking block 82, air valve 83, electromagnet 84, and the center of magnetic block 81 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com