Flour processing feeding device and flour processing equipment

A kind of feeding equipment and feeding technology, which is applied in the field of flour processing, can solve the problems of easy clogging and clogging of the feeding inlet, and achieve the effects of reasonable structure, reduced labor cost, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

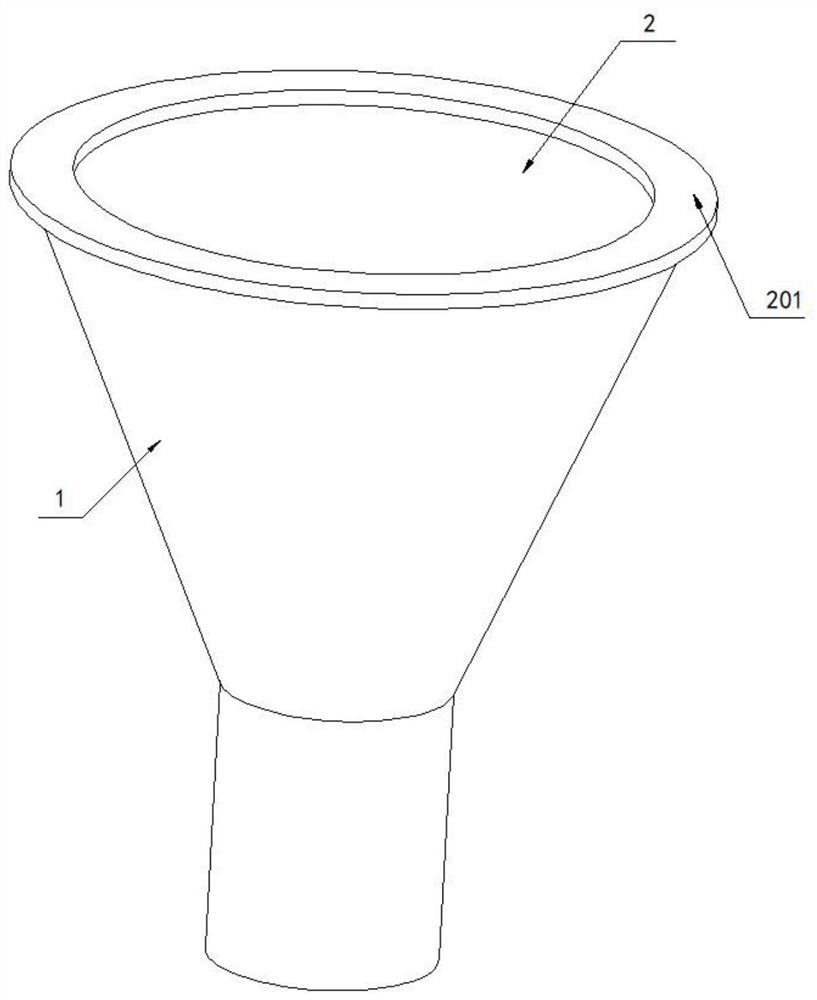

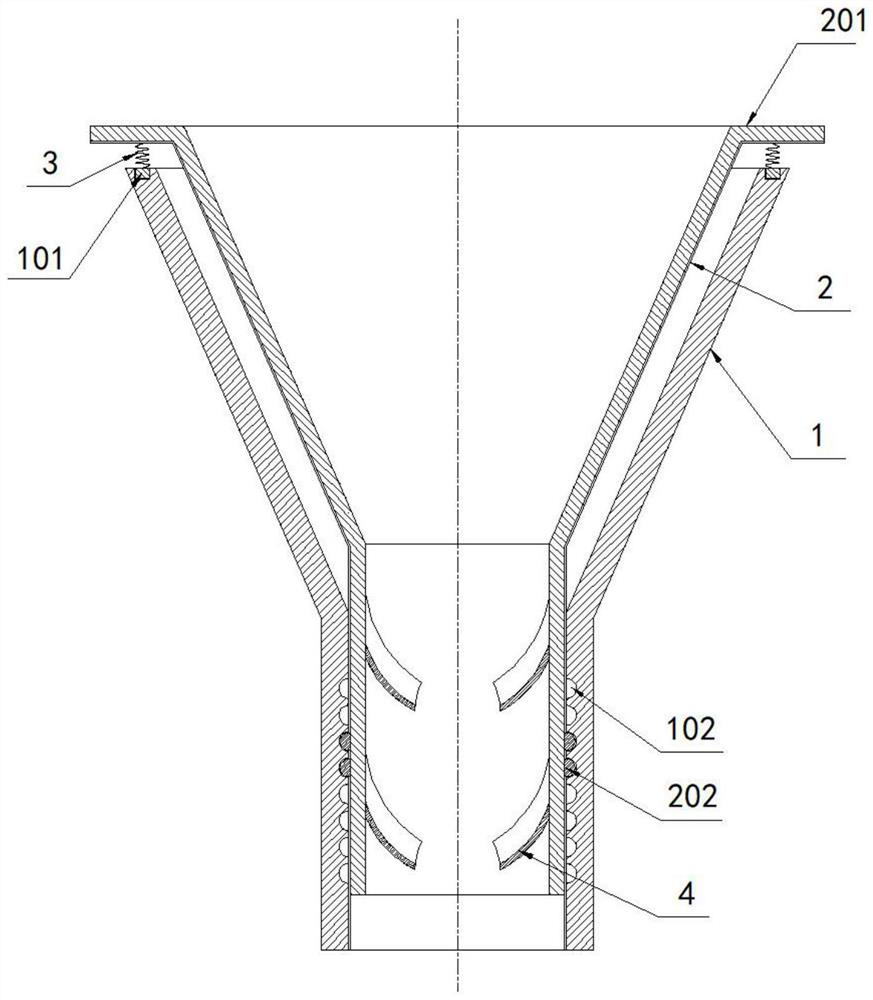

[0037] like Figure 1 - Figure 2 Shown, the present invention provides a proposed feed flour processing apparatus, comprising: an outer feed hopper 1; 2 within the feed hopper, the hopper 2 movably disposed inside the feed hopper 1 outside the feed, the feed hopper and the feed straight outer wall of the feed hopper 2 of the outer inner wall of the straight mating screw drive 1; 3 a spring, the spring 3 is disposed outside the feed hopper and the feed hopper 1 is between 2, the spring 3 for supporting the intake feed hopper 2 the feed hopper 2 and a gap between an outer hopper 1; and the vane 4, the straight on the inner wall of the feed hopper 2 is provided with at least one blade 4.

[0038] As a specific embodiment of the present invention, such as figure 2 , The outer feed hopper 1 is provided on the inner wall of the straight helical groove 102, the straight outer wall of the feed hopper 2 is provided with a helical slider 202, the slider 202 helical coil fitted in the helical...

Embodiment 2

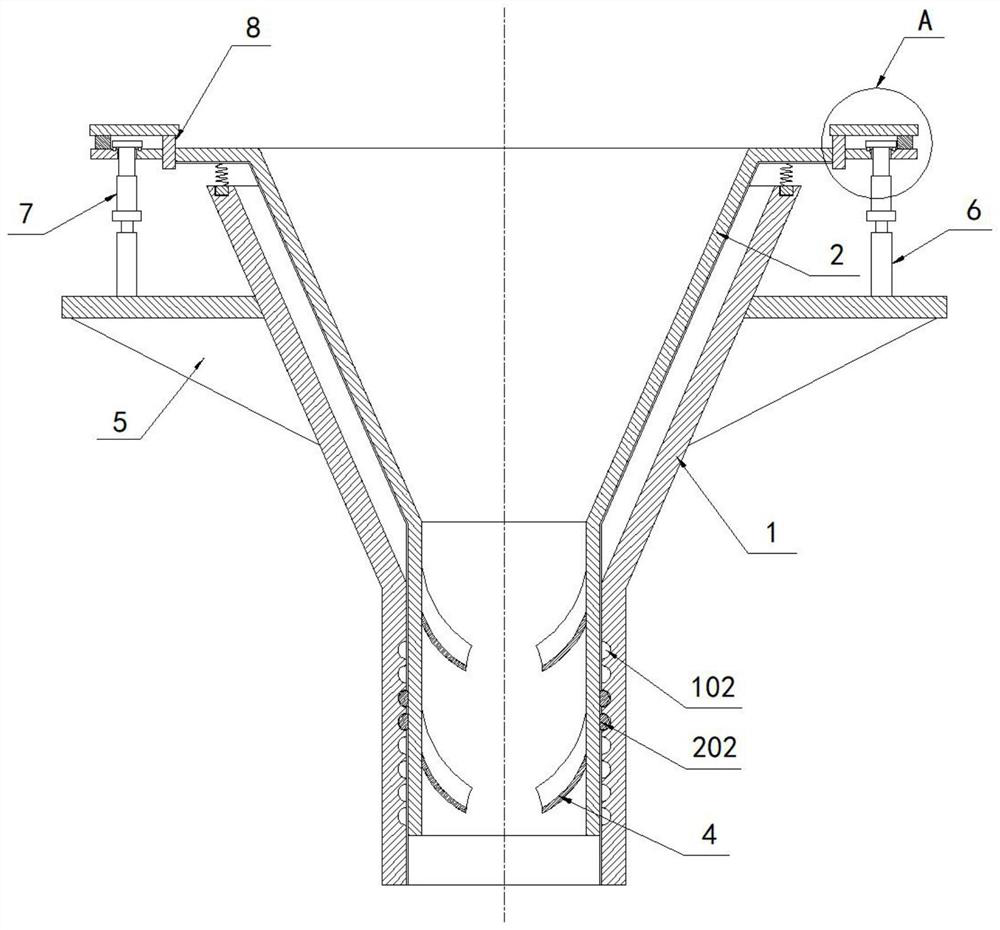

[0044] like Figure 3 - Figure 5 Increases as shown in the following technical solution based on the above embodiment according to the first aspect:

[0045] As a specific embodiment of the present invention, such as Figure 3 - Figure 5 As shown, it also includes:

[0046] An annular slide mechanism, the annular ramp mechanism concentrically fixed to the outer wall of the extension plate 201 of the ring;

[0047] Outside the outer wall 6, telescopic feed hopper mechanism 1 is fixed at least two brackets 5, the top of each bracket 5 are fixed to a telescopic mechanism 6, the piston end of the telescopic mechanism 6 is fixed to the telescopic rod 7, the upper end of extendable rod 7 slidably engaging the annular slide in the annular slide mechanism.

[0048] Telescopic mechanism 6 using telescopic cylinders, telescopic ram or cylinder motor, preferably retractable telescopic cylinder or cylinders.

[0049] As a specific embodiment of the present invention, such as Figure 3 - Figure 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com