Working face hydraulic support multi-dimensional positioning system and method

A technology of hydraulic support and positioning system, which is applied in the direction of mine roof support, earth square drilling, mining equipment, etc., which can solve the problems of many installed equipment, difficult maintenance, poor reliability, etc., and achieve the effect of strengthening the management of the working face and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

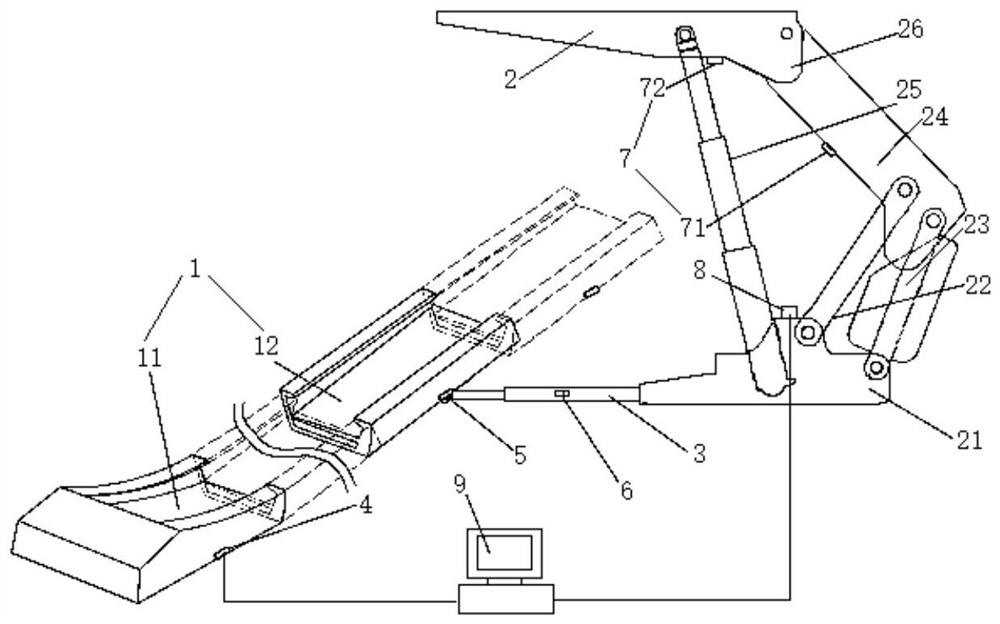

[0030] The working surface involved in this embodiment, such as figure 1 As shown, it includes a scraper conveyor 1 , several hydraulic supports 2 connected to the scraper conveyor 1 , and push rods 3 connecting the scraper conveyor 1 and the hydraulic supports 2 . The scraper conveyor 1 includes a machine head 11 and several chutes 12 connected to the machine head 11 . Each chute 12 corresponds to a hydraulic support 2 . The hydraulic support 2 includes a base 21 , a front connecting rod 22 , a rear connecting rod 23 , a shield beam 24 , a balance jack 25 and a top beam 26 . Balance jack 25, front connecting rod 22, rear connecting rod 23 are connected on the base 21 successively from front to back, and one end of front connecting rod 22, rear connecting rod 23 is fixed on the base 21, and the other end connects an end of cover beam 24, and the cover The other end of the beam 24 is hinged to one end of the top beam 26 . One end of the balance jack 25 is fixed on the base 2...

Embodiment 2

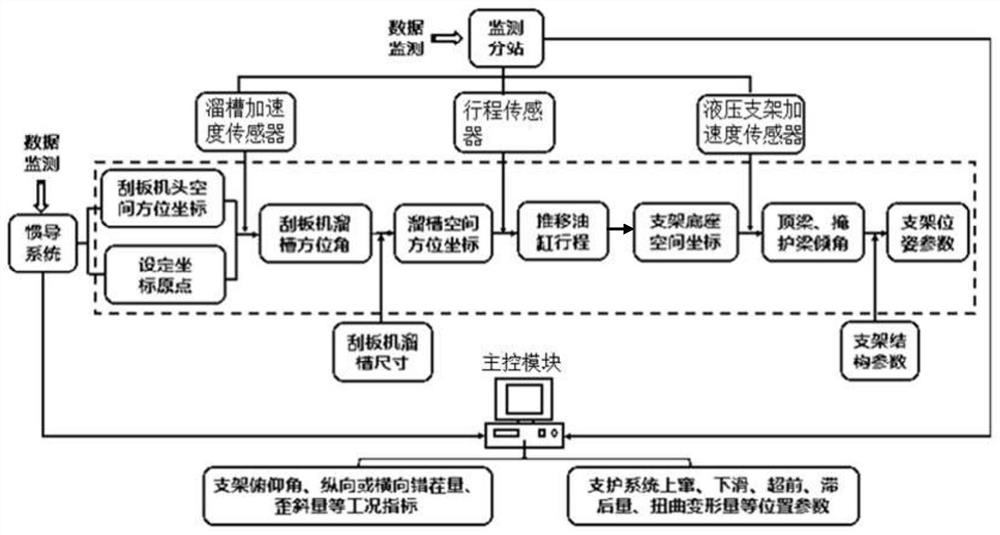

[0044] Based on the same inventive concept, this embodiment discloses a multi-dimensional positioning method for a working face hydraulic support, using any one of the above-mentioned multi-dimensional positioning systems for a working face hydraulic support, such as figure 2 shown, including the following steps:

[0045] S1. Establish the coordinate system of the head 11 of the scraper conveyor 1 through the inertial navigation module 4 .

[0046] Install the inertial navigation module 4 at the center position of the head 11 of the scraper conveyor 1, set the center position as the coordinate origin O, the direction passing through the origin O pointing to the tail is the positive direction of the X-axis, and passing the origin O points to the fully mechanized mining work The direction of surface advancement is the positive direction of the Y axis, and the direction passing through the origin O and vertically upward to the coal seam roof is the positive direction of the Z ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com