Sausage food demolding device

A technology for film removal and food, which is applied in food science, sausage making, uncoated sausage making machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides an enema food stripping device.

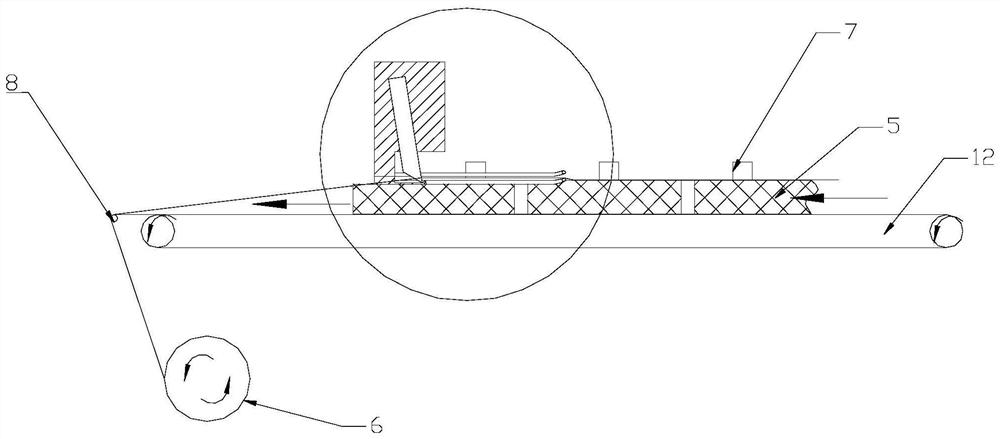

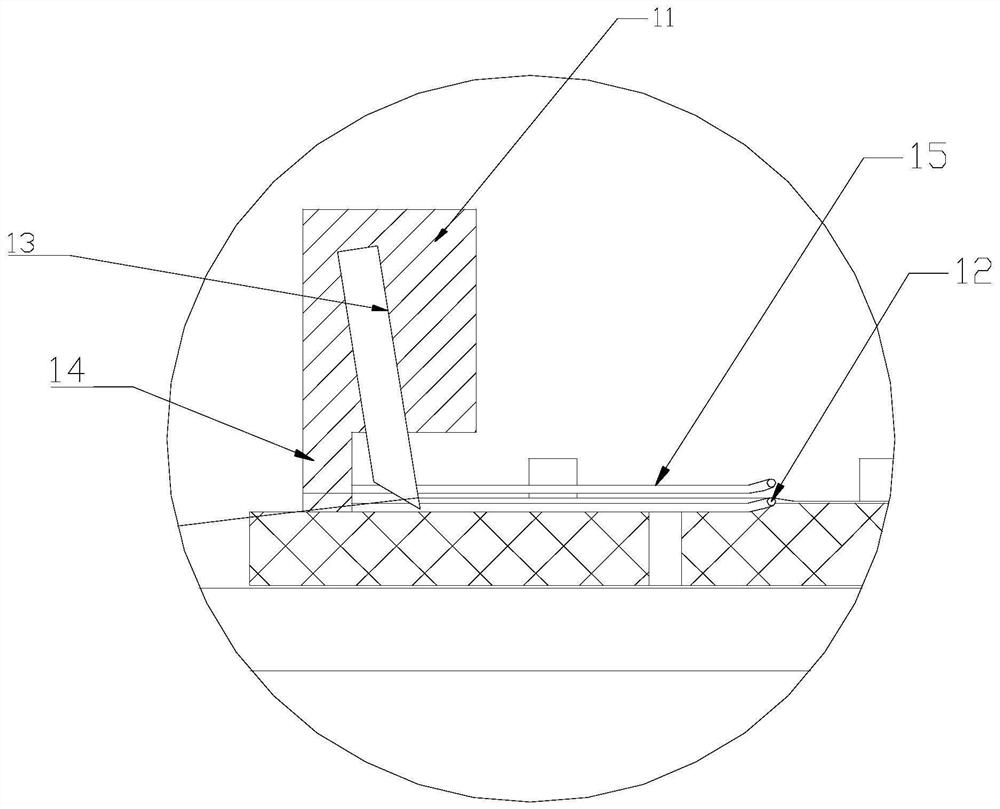

[0028] Such as Figure 1-4 As shown, an enema food stripping device includes a fixed support 10 and a stripping mechanism disposed on the fixed support 10, wherein the stripping mechanism is fixed on the fixed support 10 through a support frame.

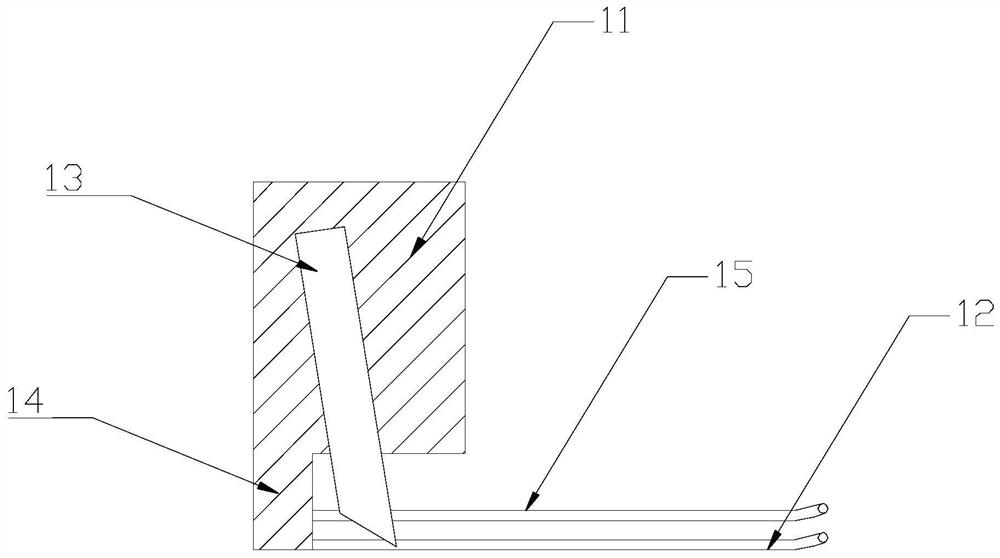

[0029] Further, the stripping mechanism 10 includes a fixed plate 11, an inner guide rod 12, a stripping blade 13, a protruding block 14, and an outer guide rod 15, wherein the protruding block 14 is an extension block at the left end of the fixed plate 11 bottom; The inner guide rod 12 is fixed on the bottom of the protruding block 14; the outer guide rod 15 is fixed on the protruding block 14 and is positioned above the inner guide rod 12; the stripping blade 13 is fixedly arranged on the fixed plate 12, specifically, the fixed plate 11 Be fixed above the fixed support 10 by a support frame; the inner guide rod 12 and the outer guide rod 15 are U-shaped guide rods, an...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that a slide rail is also provided on the fixed support 10, and the stripping mechanism is slidably arranged on the slide rail, so that the stripping mechanism can slide on the slide rail through the stripping mechanism. When the enema does not move, remove the enema.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com