Membrane removing and cutting-off device for crab sticks

A cutting device and film stripping technology, applied in food forming, metal processing, food science and other directions, can solve problems such as low production efficiency and increased labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

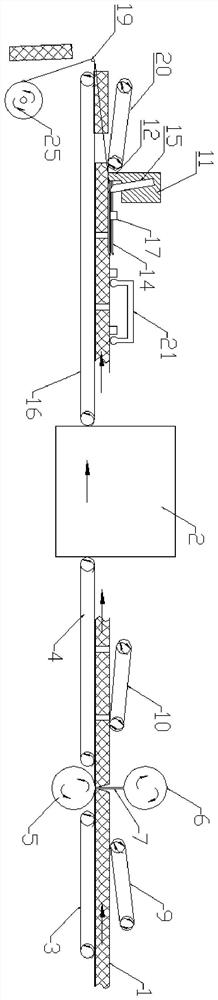

[0035] like figure 1 Shown, a kind of stripping and cutting equipment of crab sticks includes a stripping device and a cutting device arranged from left to right, wherein the cutting device is used to cut off the crab meat of crab sticks without cutting the crab sticks 1 The outer membrane is cut off; the stripping device is used to strip the outer membrane of the crab stick.

[0036] Further, the stripping and cutting equipment also includes a sizing mechanism 2, which is arranged between the cutting device and the stripping device, and the sizing mechanism 2 is used to shape the crab stick 1; making the crab stick more compact ; Specifically, the sizing mechanism 2 includes a steam box, a cooking box, or other sizing mechanisms.

[0037] The structure and principle of the cutting device and the stripping device will be described in detail below;

[0038] cutting device

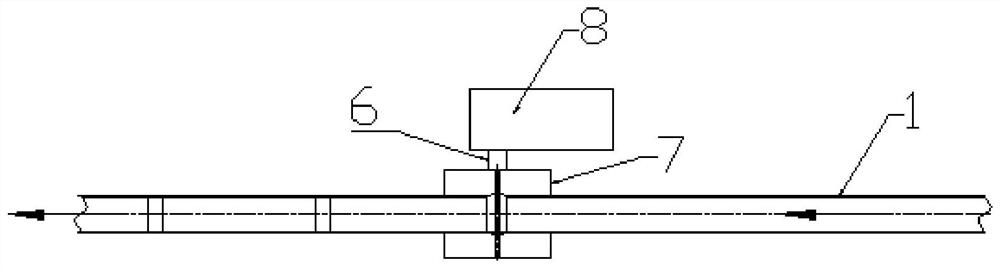

[0039] like Figure 1-3 As shown, the cutting device includes a first conveying mechanism, a crab sti...

Embodiment 2

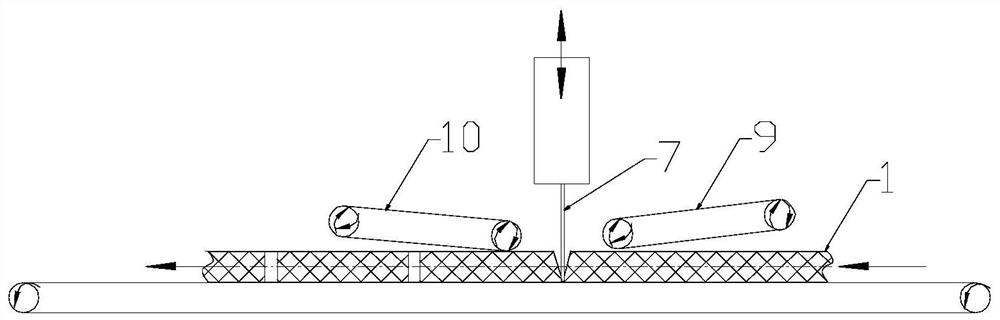

[0061] The difference between this embodiment and embodiment 1 is: as image 3 As shown, the power assembly in this embodiment is an eccentric wheel shaft connecting rod transmission linear motor motion crank mechanism, so that the operation of the eccentric wheel shaft connecting rod transmission linear motor motion crank mechanism can drive the cutting part 7 to move up and down, so that the cutting part 7 can move up and down. The up and down movement can cut off the crab meat of the crab stick 1 on the first conveying mechanism without cutting off the outer membrane of the crab stick 1 .

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that a slide rail is also provided on the second conveying mechanism, and the stripping mechanism is slidably arranged on the slide rail, so that the stripping mechanism slides on the slide rail to make the stripping The membrane mechanism can remove the membrane from the crab stick 1 without moving the crab stick 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com