Quick-release folding rocker arm

A technology of the first handle and handle, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of increased transportation costs, low assembly rate, and loss of rocker arms, and achieves improved locking stability, reduced assembly difficulty, and reduced packaging effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

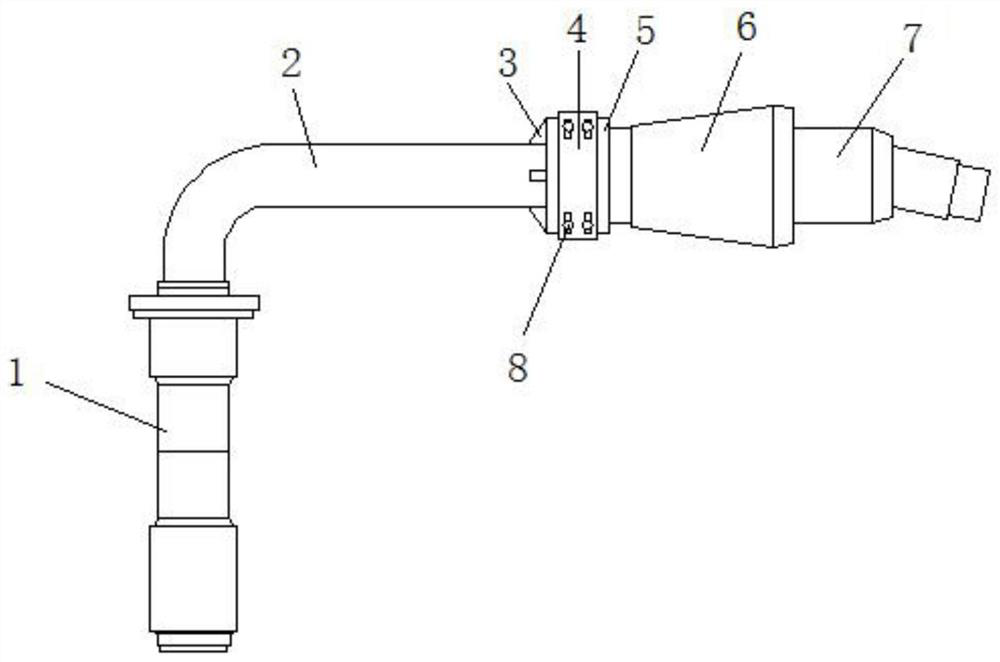

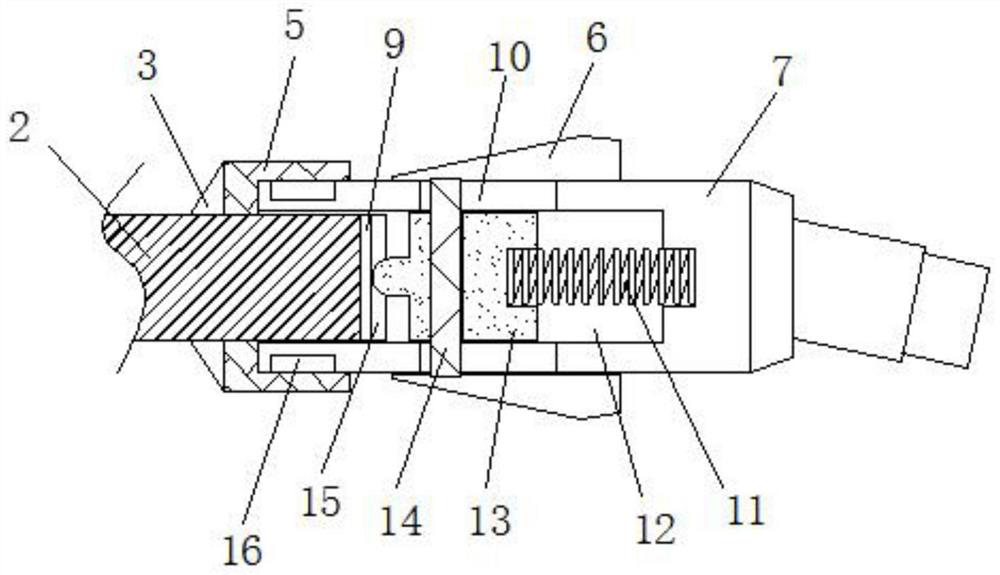

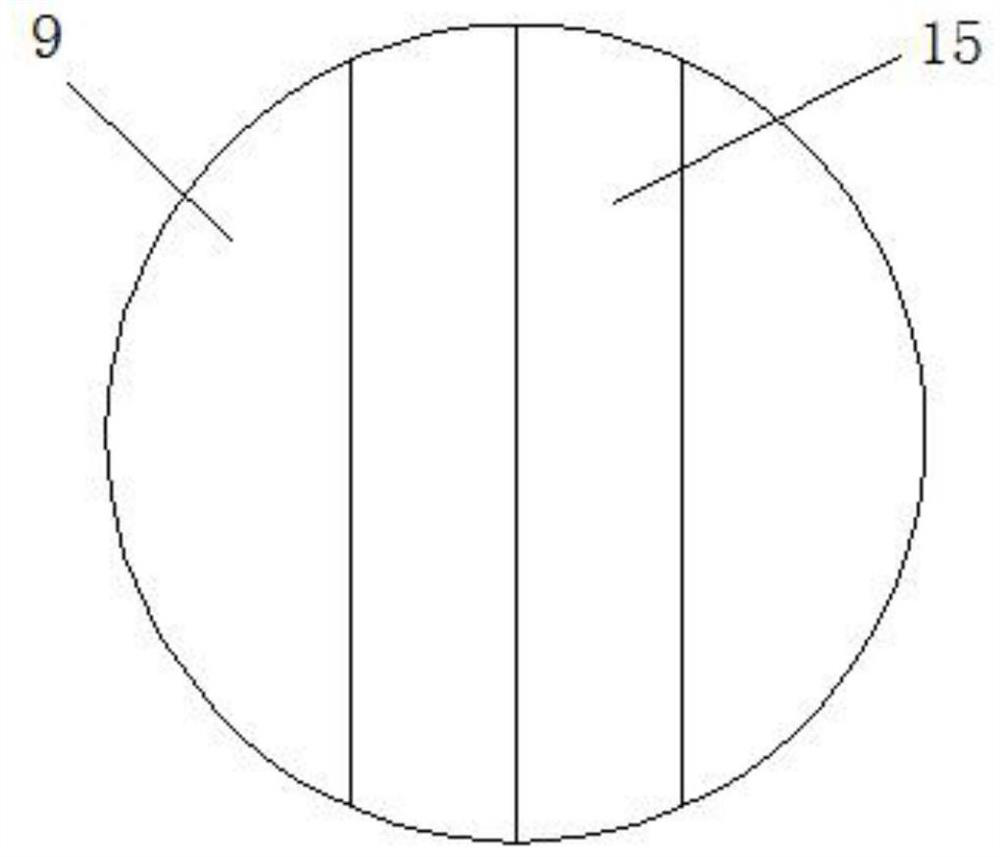

[0023] see Figure 1 to Figure 4 , the present invention provides a technical solution: a quick-release folding rocker arm, including a first handle 2 and a second handle 7, one end of the second handle 7 is provided with a mounting groove 12, and one end of the first handle 2 is placed in the mounting groove 12, the inside of the installation groove 12 is provided with a slider 13, and the two sides of the outer wall of the second handle 7 are symmetrically provided with strip holes 10, and one end of the slider 13 is provided with a jack, and the inside of the jack is penetrated by a pin rod 14 , through the designed pin rod 14, the sliding and pulling adjustment of the slider 13 is realized. Both ends of the pin rod 14 pass through the bar-shaped hole 10. Axial sliding on the top of the handle will not cause rotation, and at the same time, the sliding distance is limited. One end surface of the first handle 2 is fixed with a neck block 9, and the surface of the neck block 9...

Embodiment 2

[0028] see Figure 1 to Figure 4, the present invention provides a technical solution: a quick-release folding rocker arm, including a first handle 2 and a second handle 7, one end of the second handle 7 is provided with a mounting groove 12, and one end of the first handle 2 is placed in the mounting groove 12, the inside of the installation groove 12 is provided with a slider 13, and the two sides of the outer wall of the second handle 7 are symmetrically provided with strip holes 10, and one end of the slider 13 is provided with a jack, and the inside of the jack is penetrated by a pin rod 14 , through the designed pin rod 14, the sliding and pulling adjustment of the slider 13 is realized. Both ends of the pin rod 14 pass through the bar-shaped hole 10. Axial sliding on the top of the handle will not cause rotation, and at the same time, the sliding distance is limited. One end surface of the first handle 2 is fixed with a neck block 9, and the surface of the neck block 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com