Connecting structure at joint of wall aluminum formwork and wood formwork and construction method of connecting structure

A technology for connecting structure and wood formwork, applied in the connection of formwork/formwork/work frame, formwork/formwork/work frame, building structure, etc., can solve the problem of poor strength of wood formwork, low work efficiency and easy occurrence Crack and other problems, to achieve the effect of quick connection and fixation, firm fixation, and prevention of rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

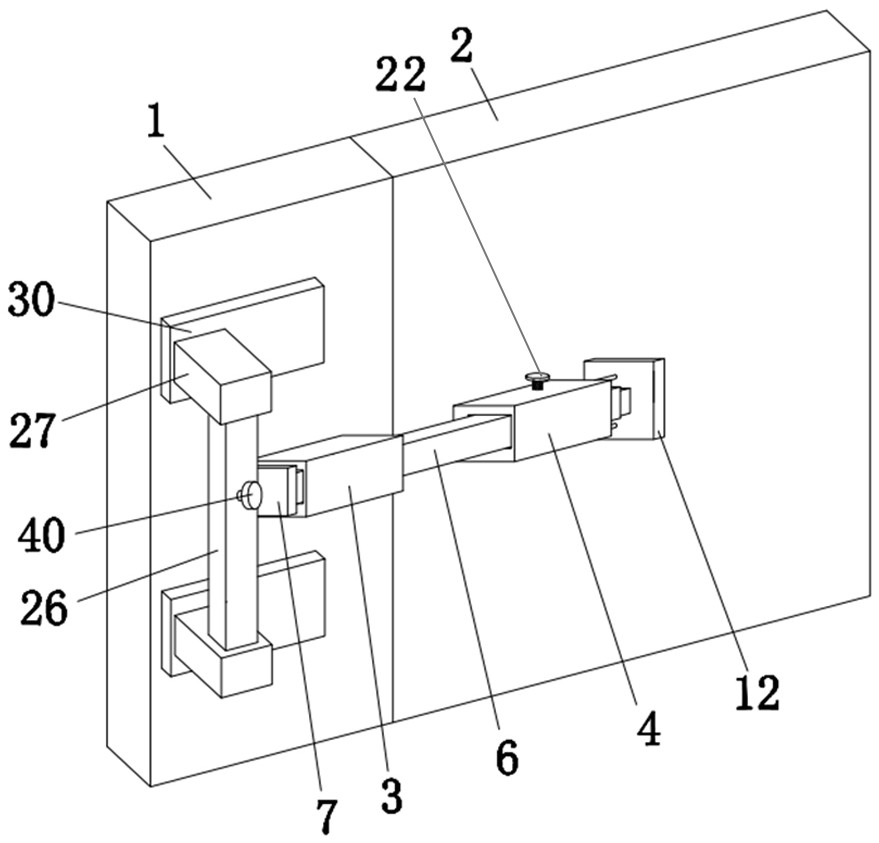

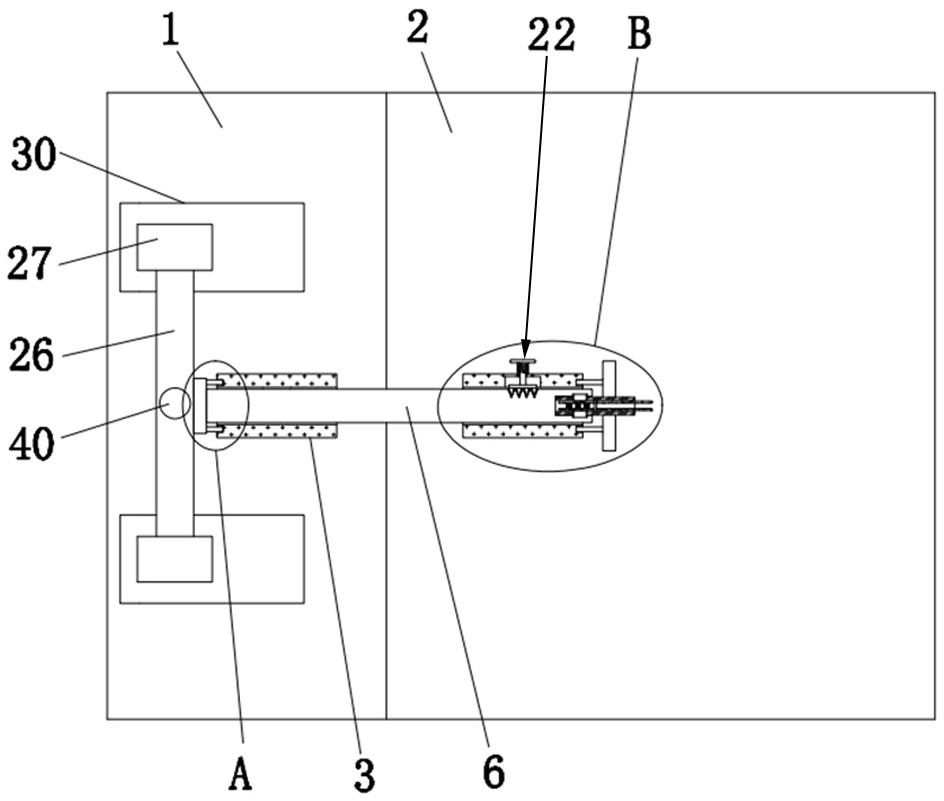

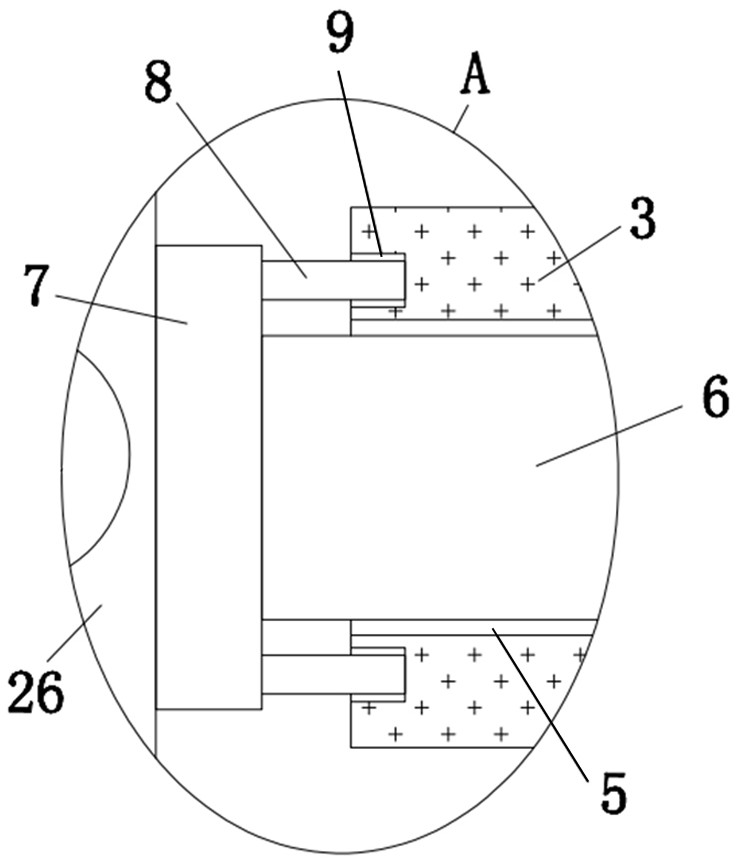

[0037] Such as Figure 1-6 As shown, the connection structure of the joint between the aluminum formwork and the wood formwork of the wall is used to fix the wood formwork 1 and the aluminum formwork 2; A connection plate 7, a second connection plate 12, a locking member 22, a support mechanism and a clamping assembly; the first connection block 3 is fixedly connected to the wooden formwork 1, and the first connection block 3 is provided with a horizontal second A hole 5, on the end face of the first connection block 3 away from the side of the aluminum formwork 2, first positioning grooves 9 are respectively arranged on the upper and lower sides of the first hole 5; the second connection block 4 is fixedly connected to the aluminum formwork 2, and the second connecting block 4 is provided with a transverse second channel 23, on the end face of the second connecting block 4 away from the wood formwork 1, on the upper and lower sides of the second channel 23 are respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com