On-load double-shaft multi-stage neutral-gear-free transmission with engaged gear first and disengaged gear later

A technology with load and transmission, applied to components with teeth, instruments, belts/chains/gears, etc., can solve problems such as difficult operation, difficult shifting, and tooth collision, and achieves compact structure, easy shifting, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

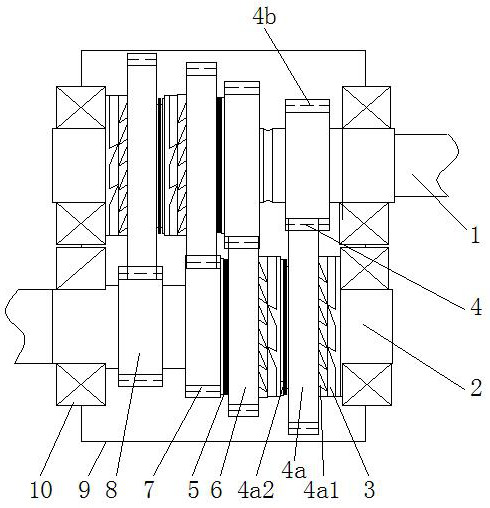

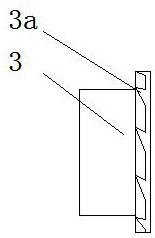

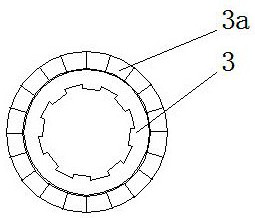

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 ,, Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , a dual-shaft multi-stage non-neutral transmission with load advanced gear and then off-gear, the lower box body 9 and the upper box body 11 form the box body of the transmission, and parallel input shafts 1 and output shafts 2 are arranged in the box body, Between the input shaft 1 and the output shaft 2, there are 2-10 constant meshing gears with different speed ratios. The constant meshing gears are composed of a fixed gear 4b and an end clutch gear 4a, and the end clutch gear 4a moves Cooperate with the sleeve of the end face clutch pawl sleeve 3, the clutch pawl sleeve 3 is connected to the shaft by a spline, the end face clutch gear 4a can slide along the axial direction of the end face clutch pawl sleeve 3; the fixed gear 4b is fixed On one shaft, the clutch pawl sleeve 3 is fixed on the other shaft; o...

Embodiment 2

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 ,, Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , a dual-shaft multi-stage non-neutral transmission with load advanced gear and then off-gear, the lower box body 9 and the upper box body 11 form the box body of the transmission, and parallel input shafts 1 and output shafts 2 are arranged in the box body, Between the input shaft 1 and the output shaft 2, there are 2-10 constant meshing gears with different speed ratios. The constant meshing gears are composed of a fixed gear 4b and an end clutch gear 4a, and the end clutch gear 4a moves Cooperate with the sleeve of the end face clutch pawl sleeve 3, the clutch pawl sleeve 3 is connected to the shaft by a spline, the end face clutch gear 4a can slide along the axial direction of the end face clutch pawl sleeve 3; the fixed gear 4b is fixed On one shaft, the clutch pawl sleeve 3 is fixed on the other shaft; o...

Embodiment 3

[0035] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 ,, Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , a dual-shaft multi-stage non-neutral transmission with load advanced gear and then off-gear, the lower box body 9 and the upper box body 11 form the box body of the transmission, and parallel input shafts 1 and output shafts 2 are arranged in the box body, Between the input shaft 1 and the output shaft 2, there are 2-10 constant meshing gears with different speed ratios. The constant meshing gears are composed of a fixed gear 4b and an end clutch gear 4a, and the end clutch gear 4a moves Cooperate with the sleeve of the end face clutch pawl sleeve 3, the clutch pawl sleeve 3 is connected to the shaft by a spline, the end face clutch gear 4a can slide along the axial direction of the end face clutch pawl sleeve 3; the fixed gear 4b is fixed On one shaft, the clutch pawl sleeve 3 is fixed on the other shaft; o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com