Gear transmission case

A gearbox and gear technology, applied in the direction of belts/chains/gears, components with teeth, fluid transmission devices, etc., can solve the problems of frequent gear shifting, multiple gear positions, complex structure, etc., and achieve good fastening effect, The effect of large transmission torque and uniform transmission force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

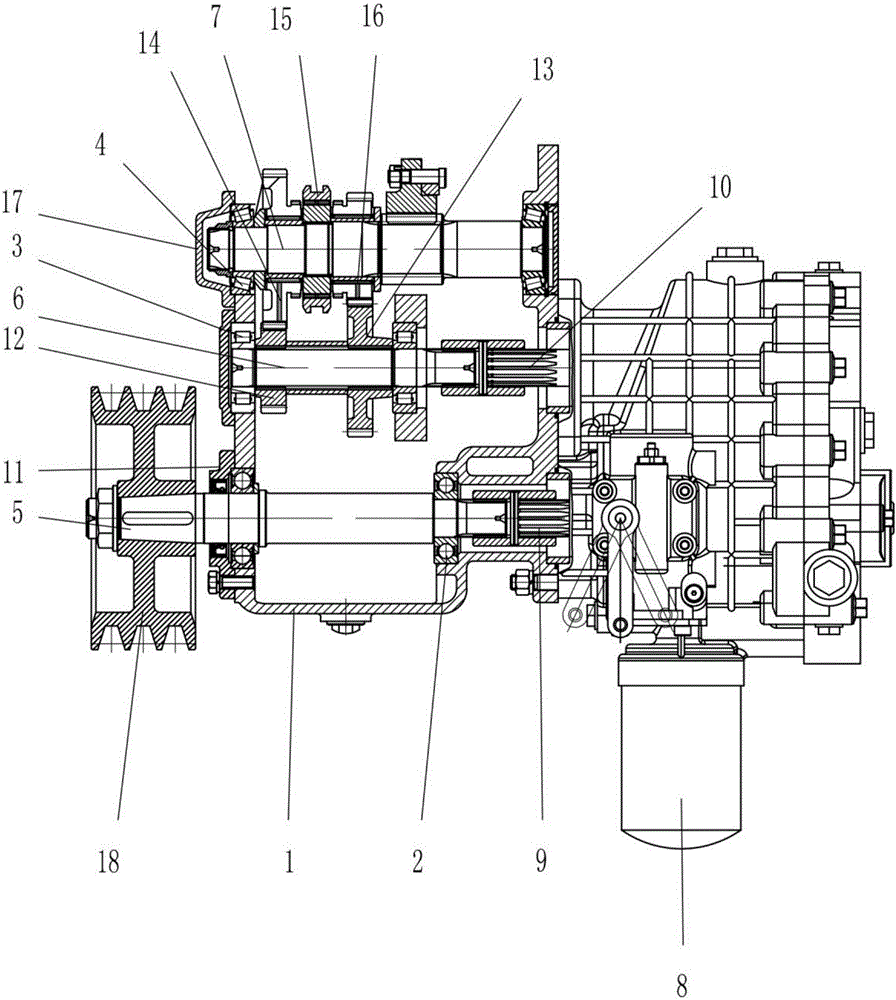

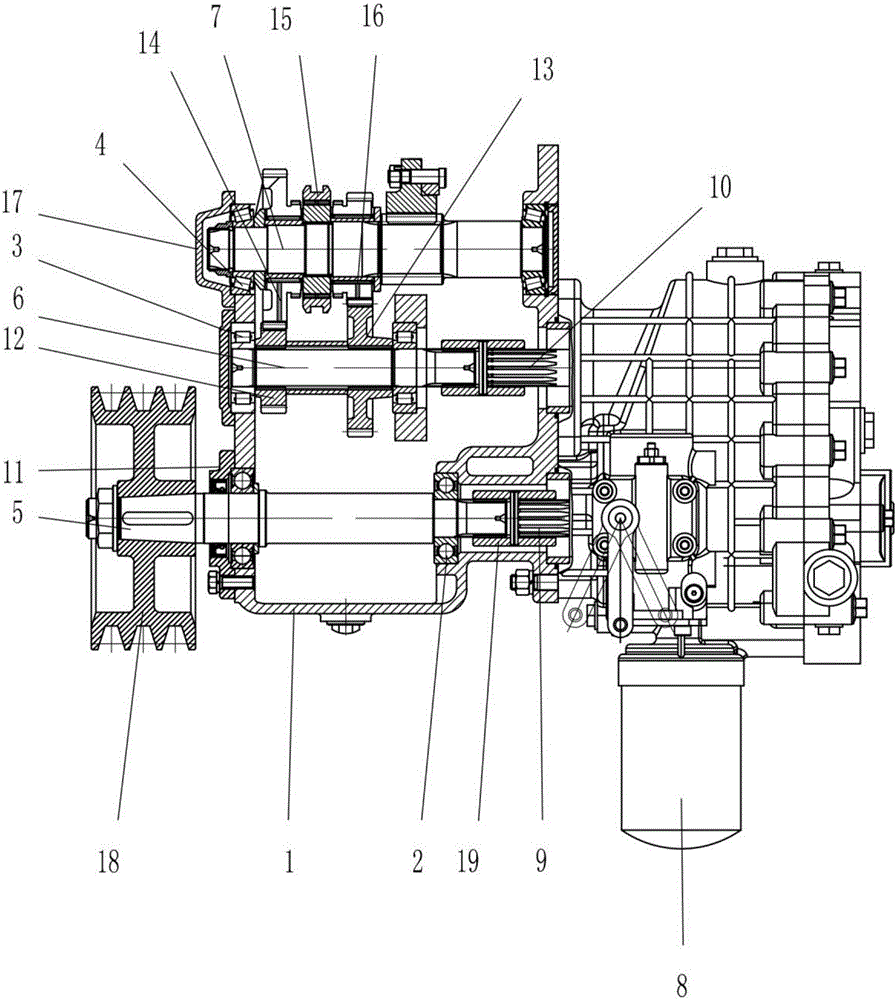

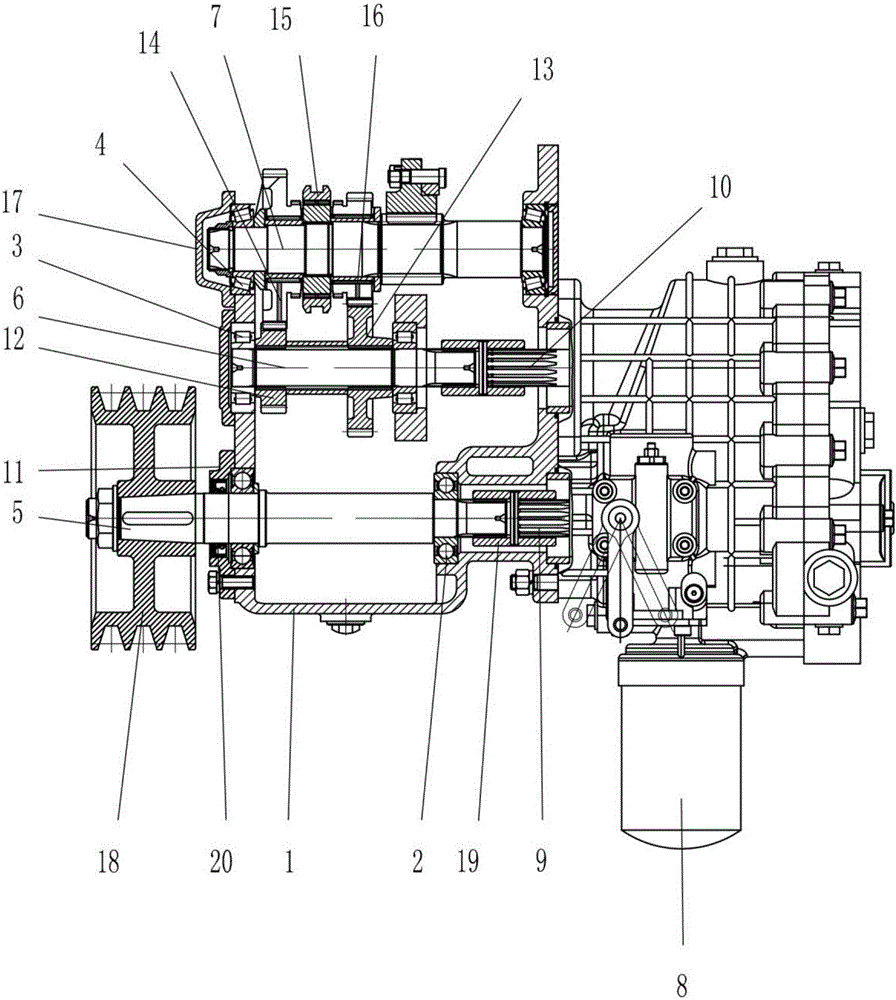

[0032] A gear transmission such as Figure 1-6 As shown, it includes main box 1, first bearing 2, second bearing 3, third bearing 4, first rotating shaft 5, second rotating shaft 6, third rotating shaft 7, HST hydraulic stepless transmission device 8, first HST output Shaft 9, second HST output shaft 10, gland 11, high-grade driving gear 12, low-grade driving gear 13, high-grade driven gear 14, gear hub sleeve 15, low-grade driven gear 16, rear cover 17, input pulley 18, main box 1 The first bearing 2, the second bearing 3 and the third bearing 4 are arranged inside, the first rotating shaft 5 is installed on the first bearing 2, the second rotating shaft 6 is installed on the second bearing 3, and the second rotating shaft 6 is installed on the third bearing 4 Three rotating shafts 7, HST hydraulic continuously variable transmission device 8 is provided on the side of main box 1, HST hydraulic continuously variable transmission device 8 is provided with a first HST output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com