Chain-transmission positioning device

A positioning device and positioning pin technology, which is applied in the direction of transmission devices, portable lifting devices, hoisting devices, etc., can solve the problems of large pitch error of chain teeth, uneven force of chain transmission, and unstable transmission, etc. Uniform, not easy to loosen or deform the chain tooth structure, and the effect of firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

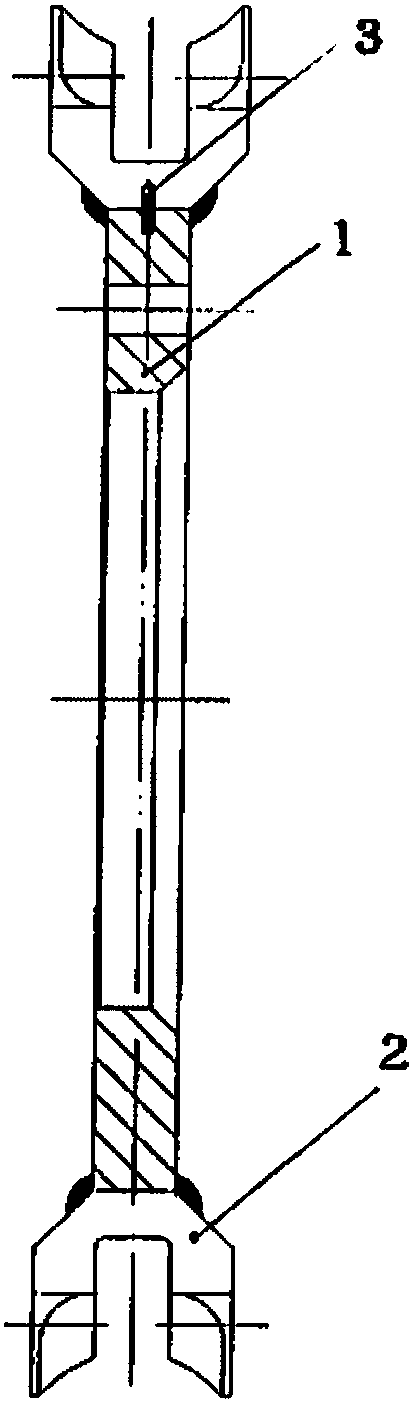

[0008] see figure 1 , the present invention includes a sprocket body 1, on the sprocket body 1 uniformly distributed and fixed sprocket teeth 2 in the shape of concave teeth, positioning pins 3 for positioning the sprocket teeth on the sprocket body.

[0009] The invention adopts the concave tooth type, which has large bearing capacity, high strength and high precision. The biggest feature is to improve the meshing performance of the chain and the dragging sprocket, and it has a strong adaptability to the large deviation of the chain manufacturing. The chain forms a deflection between the dragging sprockets, which can automatically tension the running slag extractor, so there is no need to frequently tension and shorten the chain. The chain runs in the tooth groove of the dragging sprocket, which has good guiding performance and is not easy to drop the chain. Even if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com