Double-shifting-fork gear shifting structure, gearbox and vehicle

A technology of shift fork shaft and shift fork, applied in the field of gearbox, can solve the problems of unfriendly ergonomics, out-of-gear, shift fork wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

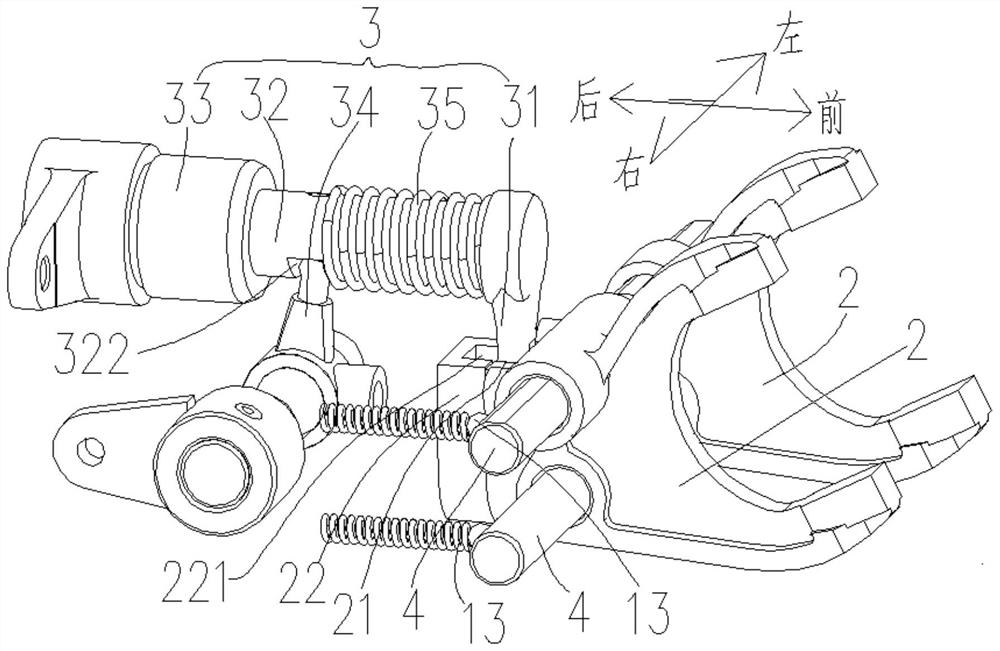

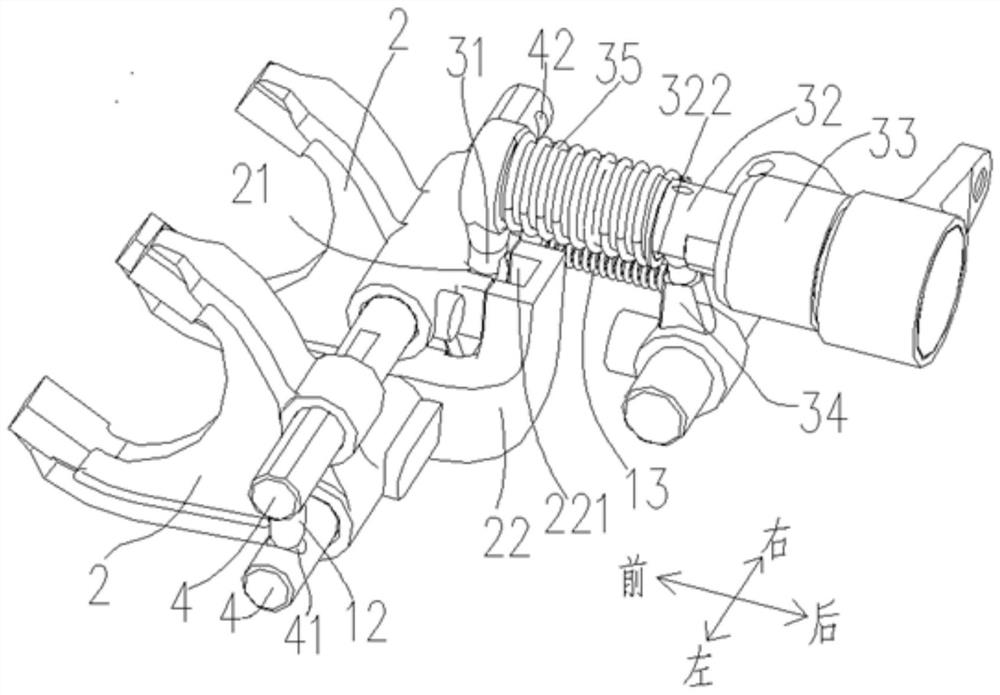

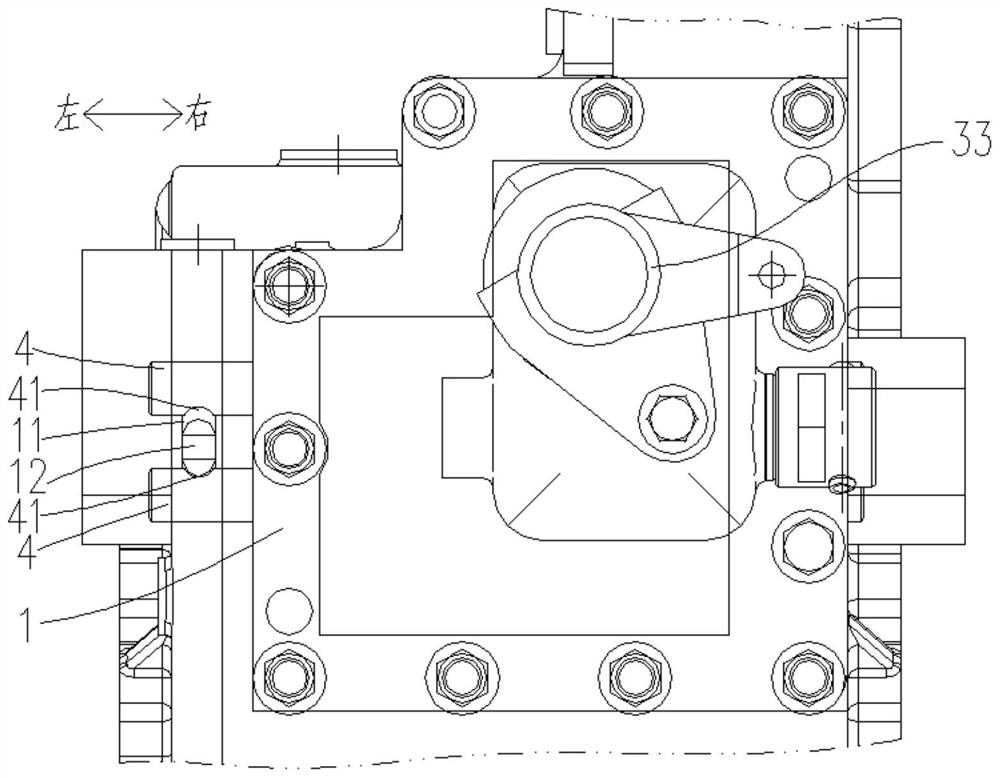

[0035] Such as Figure 1-Figure 7 As shown, this embodiment provides a double-fork shift structure, including a housing 1, two shift forks 2, a drive assembly 3 and two fork shafts 4 installed on the housing 1 ;

[0036] The two shift forks 2 are arranged vertically, and are distributed at intervals along the left and right directions, and the fork openings of the two shift forks 2 are all facing forward;

[0037] The two shift fork shafts 4 are arranged horizontally along the left and right directions and are slidably connected with the housing 1, and are distributed at intervals along the up and down directions, and the two shift fork shafts 4 are connected to the two shift forks 2 one by one. Correspondingly, each said shift fork shaft 4 is connected and fixed with the corresponding said shift fork 2, and is slidably connected with another said shift fork 2, and any one of said shift fork shafts 4 can be relative to said shift fork. The housing 1 slides left and right and...

Embodiment 2

[0049] This embodiment provides a gearbox, including the double shift fork shift structure as described in Embodiment 1 (the two shift forks of the double shift fork shift structure act on the two shift forks on the same transmission shaft on the gearbox. a clutch sleeve).

Embodiment 3

[0051] This embodiment provides a kind of vehicle, comprises gearbox as described in embodiment 2, and this vehicle can be engineering vehicle also can be agricultural vehicle (especially suitable for crawler type engineering vehicle or crawler type agricultural vehicle, as crawler excavator , crawler bulldozers, crawler harvesters, etc.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com