Microwave oven with integrated lower surface heating plate

A technology for microwave ovens and heating plates, applied in the field of microwave ovens, can solve the problems of hindering the heating of lower heating elements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

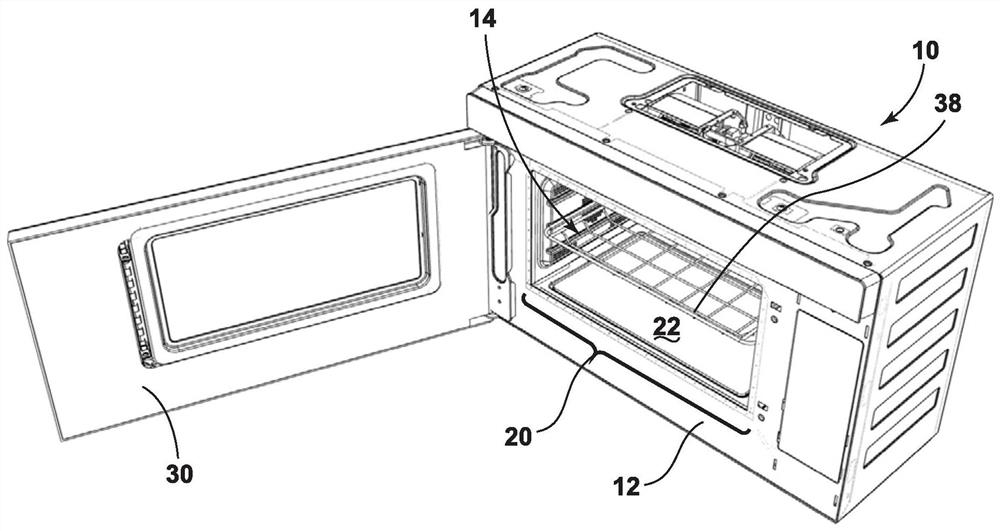

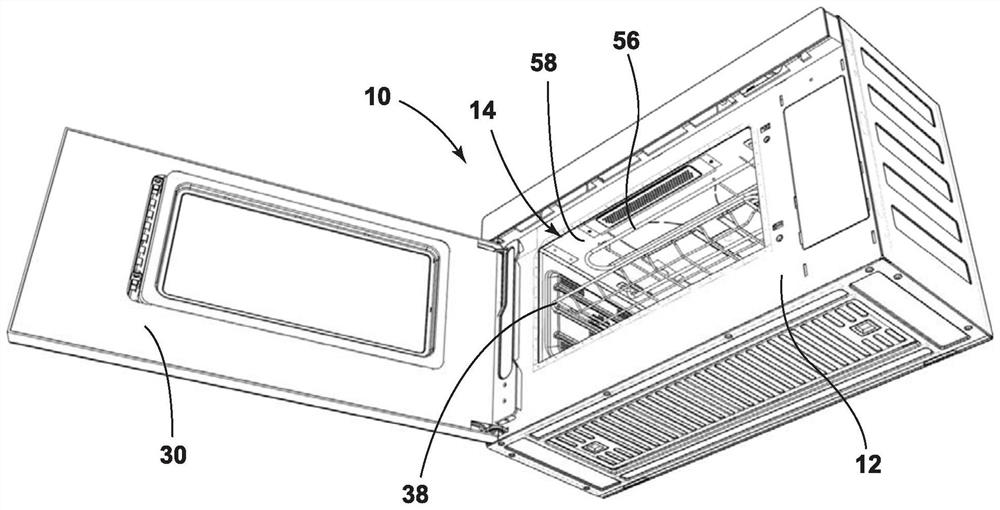

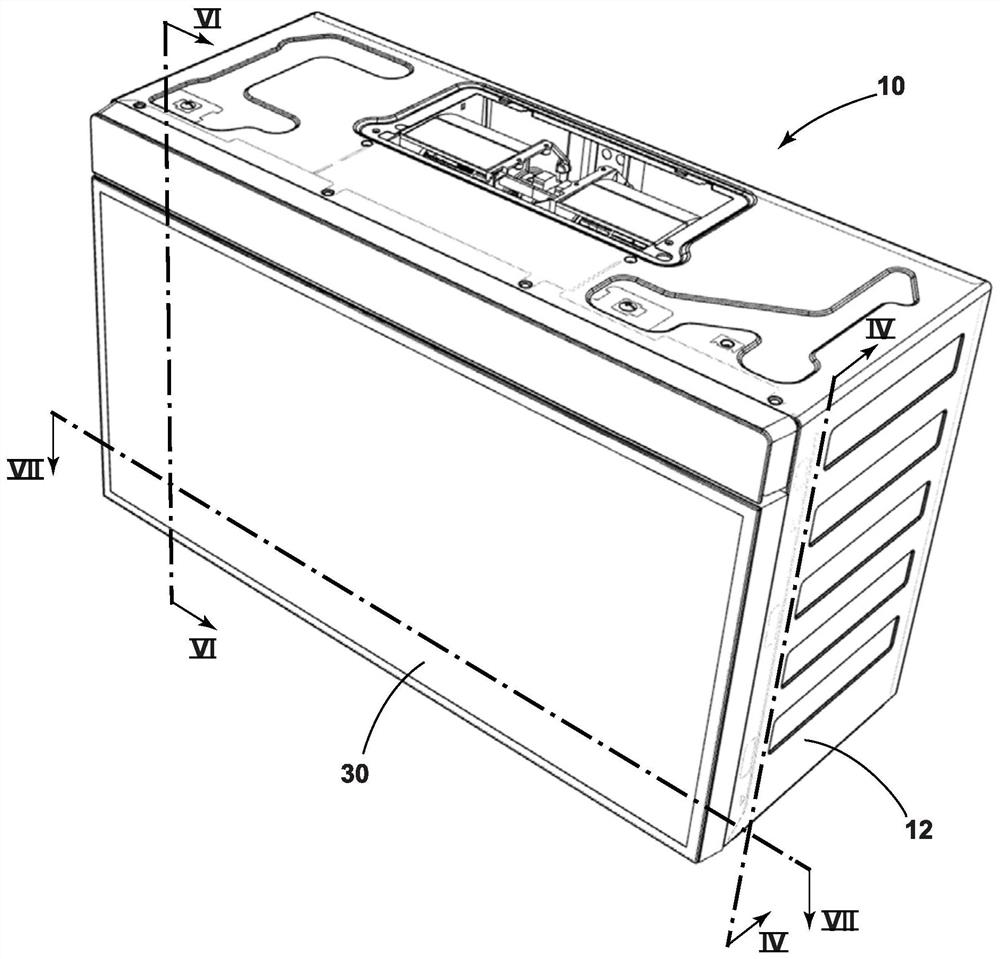

[0017] The presently shown embodiments consist primarily of a combination of equipment components related to a microwave oven. Thus, where appropriate, apparatus components and method steps have been represented by conventional symbols in the drawings, showing only those specific details that are relevant to an understanding of the embodiments of the disclosure, so as to avoid obscuring the disclosure with details, which Details will be apparent to one of ordinary skill in the art having the benefit of the description herein. In addition, the same reference numerals denote the same elements in the specification and drawings.

[0018] For the purposes of this description, the terms "upper", "lower", "right", "left", "rear", "front", "vertical", "horizontal" and their derivatives shall be used as such figure 1 This disclosure is oriented in . Unless otherwise stated, the term "front" shall refer to the surface of the element closer to the intended viewer, and the term "rear" s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com