Method for manufacturing black borosilicate glass by vacuum coating

A borosilicate glass and coating equipment technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of lack of mature technology and achieve the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

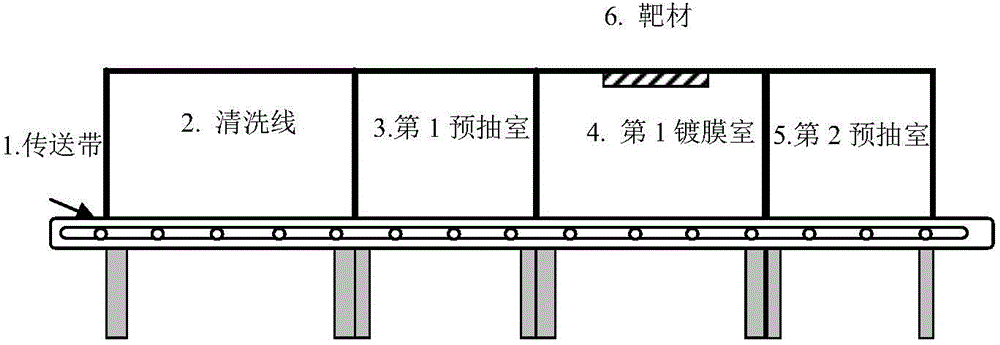

[0028] The invention provides a multi-chamber continuous magnetron sputtering coating equipment, the coating equipment structure is as follows figure 1 As shown, it includes a conveyor belt 1 and three vacuum chambers, and the three vacuum chambers include a first pre-pumping chamber 3 , a first coating chamber 4 and a second pre-pumping chamber 5 . The first pre-pumping chamber 3 is located in front of the first coating chamber 4, the second pre-pumping chamber 6 is located behind the first coating chamber 4, and the conveyor belt circulates in the first pre-pumping chamber, the first coating chamber, and the second pre-pumping chamber Turn to transport borosilicate glass to be coated. In addition, a glass cleaning line 2 is provided for cleaning and air-drying the borosilicate glass to be coated. The glass cleaning line 2 is integrated with the first pre-extraction chamber 3 and the conveyor belt passes through the glass cleaning line 2 at the same time. After the cleaned g...

Embodiment 2

[0048] Embodiment 2 provides a kind of multi-chamber continuous magnetron sputtering coating equipment, described coating equipment except including all structures of embodiment 1, also comprises the second coating chamber, the second coating chamber is located in the first coating chamber 4 And between the second pre-pumping chamber 5.

[0049] Correspondingly, in the method for preparing black borosilicate glass in Example 2, the borosilicate glass to be coated enters the second coating chamber for further coating treatment after the coating treatment in the first coating chamber 4, and then enters the second coating chamber. Pre-pumping chamber 5. In embodiment 2, the metal nitride thin film is deposited in the first coating chamber, and the metal nitride thin film is also deposited in the second coating chamber.

[0050] The second coating chamber is filled with argon-nitrogen mixed gas, the magnetron target applies a voltage and generates a glow discharge, and the argon-...

Embodiment 3

[0054] Embodiment 3 provides a multi-chamber continuous magnetron sputtering coating equipment, the continuous sputtering coating equipment includes all the structures of Embodiment 1, and also includes at least a second coating chamber and a third coating chamber, at least The second coating chamber and the third coating chamber are located between the first coating chamber 4 and the second pre-pumping chamber 5 .

[0055] Correspondingly, in the method for preparing black borosilicate glass in embodiment 3, the borosilicate glass to be coated enters at least the second coating chamber and the third coating chamber for further coating treatment after the coating treatment in the first coating chamber 4 , and then enter the second pre-pumping chamber 5. In Embodiment 3, each coating chamber deposits a metal nitride film, such as a TiAlN film, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com