High-speed train axle box bearing dynamic test equipment

A dynamic testing technology for axle box bearings, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., and can solve the problems of lack of service life testing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

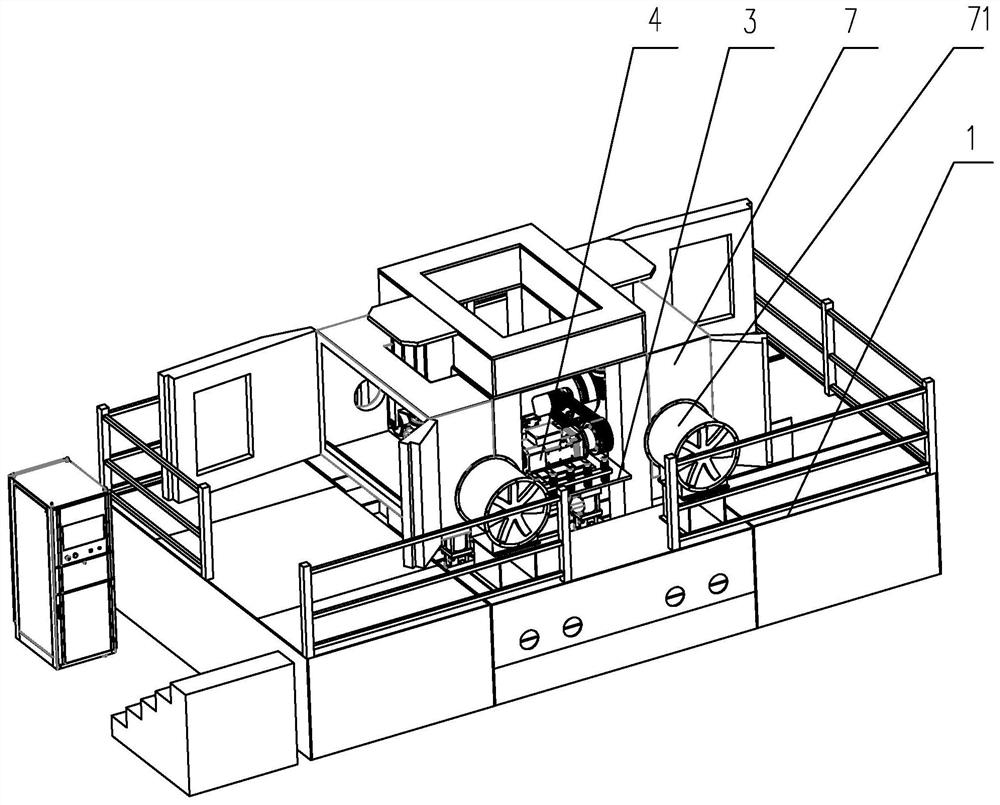

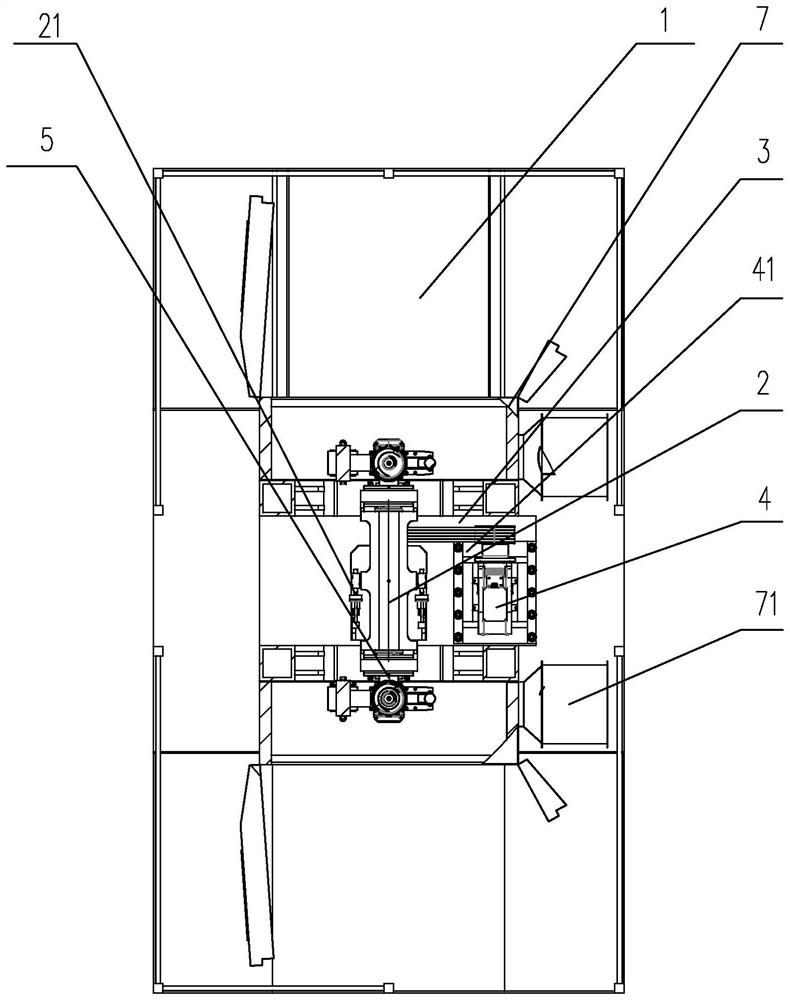

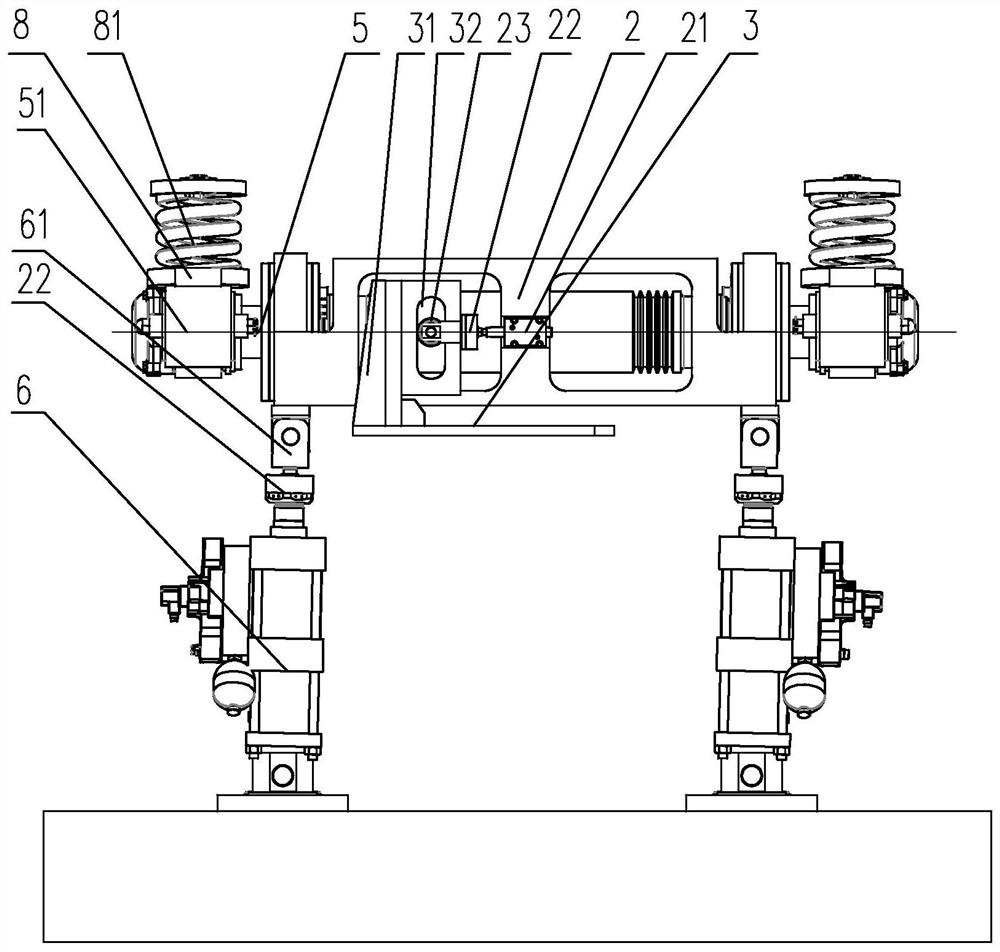

[0027] Embodiments of the high-speed rail axle box bearing dynamic testing equipment of the present invention are for example Figure 1 to Figure 7 : including a frame 1 and a mounting seat 2, two connection seats are arranged on the bottom surface of the frame 1, and a vibration loader 6 is respectively swingably arranged on the two connection seats, and the output end of the vibration loader 6 is arranged along the height direction, The mounting base 2 is rotatably connected with the output end of the vibration loader 6 through a hinge, the frame 1 is provided with a test bench 3 in the circumferential direction of the mounting base 2, and a rotating main shaft 5 is arranged on the mounting base 2 for rotation. The two ends of the main shaft 5 are provided with mounting grooves for installing the high-speed rail axle box 51, and the test bench 3 is provided with a driving motor 4 for driving the rotating main shaft 5 to rotate. The axial loader 21 that drives the mounting se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com