Continuous sampling device and method for SO3 at smoke outlet of chimney of coal-fired power plant

A technology for smoke exhaust from chimneys and coal-fired power plants, applied in sampling devices, sampling, measuring devices, etc., can solve problems such as discontinuous sampling, and achieve the effect of solving intermittent sampling and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

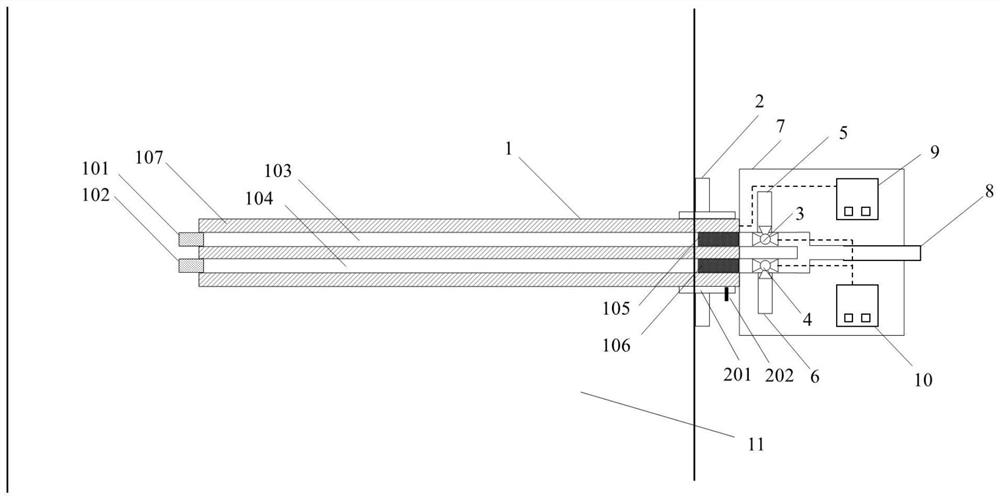

[0027] The first embodiment of the present application provides a coal-fired power plant chimney exhaust port SO 3 Continuous sampling devices such as figure 1 As shown, it includes: high temperature sampling probe 1, mounting flange 2 and sampling box shell 7. The high temperature sampling probe rod 1 extends into the chimney exhaust port 11 , and the high temperature sampling probe rod 1 is fixed on the outer wall of the chimney exhaust port 11 through the mounting flange 2 ;

[0028] The high temperature sampling probe 1 includes an alloy filter 1 101 , an alloy filter 2 102 , an inner tube 1 103 , an inner tube 2 104 , a quartz filter element 1 105 , a quartz filter element 2 106 and a heating insulation layer 107 . Alloy filter one 101 is connected with one end of inner tube one 103, and the other end of inner tube one 103 is connected with quartz filter element one 105 to form a sampling channel; alloy filter two 102 is communicated with one end of inner tube two 104, a...

Embodiment 2

[0032] The second embodiment of the present application provides a coal-fired power plant chimney exhaust port SO 3 The working method of the continuous sampling device includes the following steps:

[0033] S1. The mounting flange 2 is installed on the outer wall of the chimney exhaust port 11 of the coal-fired power plant. The high temperature sampling probe 1 is fixed on the chimney exhaust port 11 through the mounting flange 2. By moving the high temperature sampling probe 1 and the mounting flange The relative position of 2 adjusts the length of the high temperature sampling probe 1 extending into the inside of the chimney exhaust port 11 . When the device is running, set the temperature of the temperature controller 9, and the SO must be guaranteed within the set temperature range. 3 In the gaseous state, preferably 300°C, the heating and insulating layer 107 is heated, maintained at the set temperature and kept stable.

[0034] S2. After the temperature is stable, sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com