Preparation device and preparation method of environment-friendly composite concrete water reducing agent

A technology for concrete water reducing agent and preparation equipment, which is applied in the direction of chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical/physical chemical fixed reactors, etc., and can solve the problem of large temperature fluctuations and large temperature differences in reaction liquids , Affect the preparation of water reducing agent, etc., to avoid large temperature fluctuations and increase the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

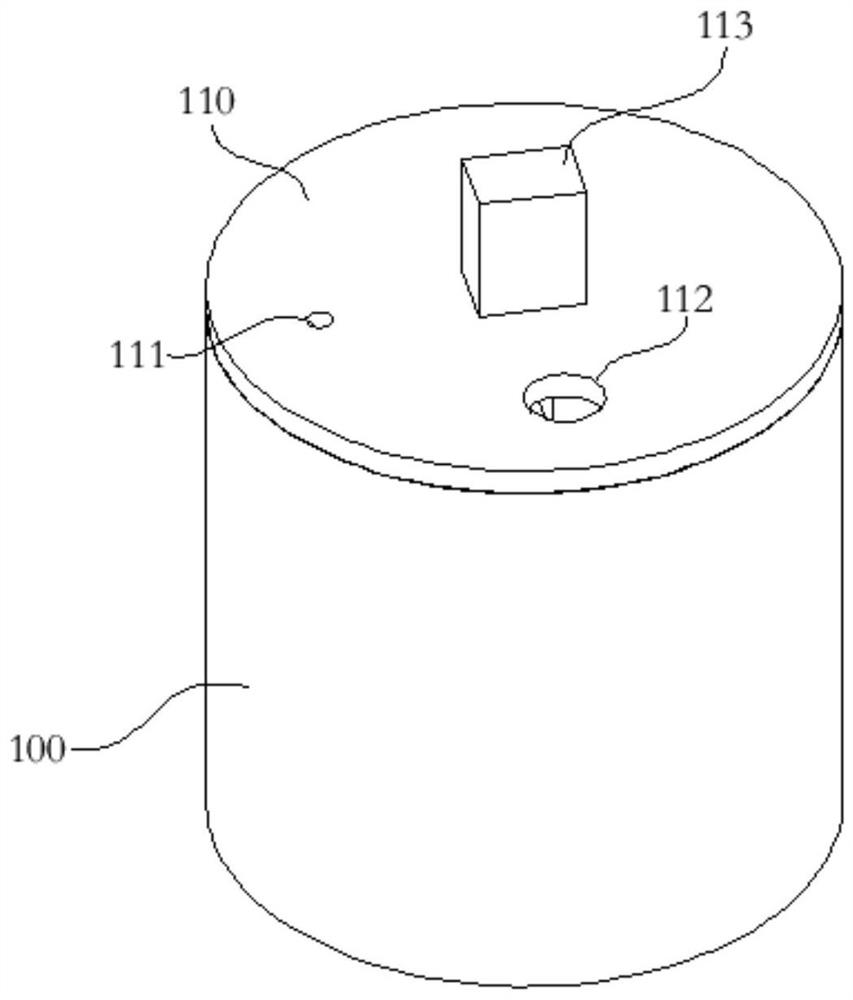

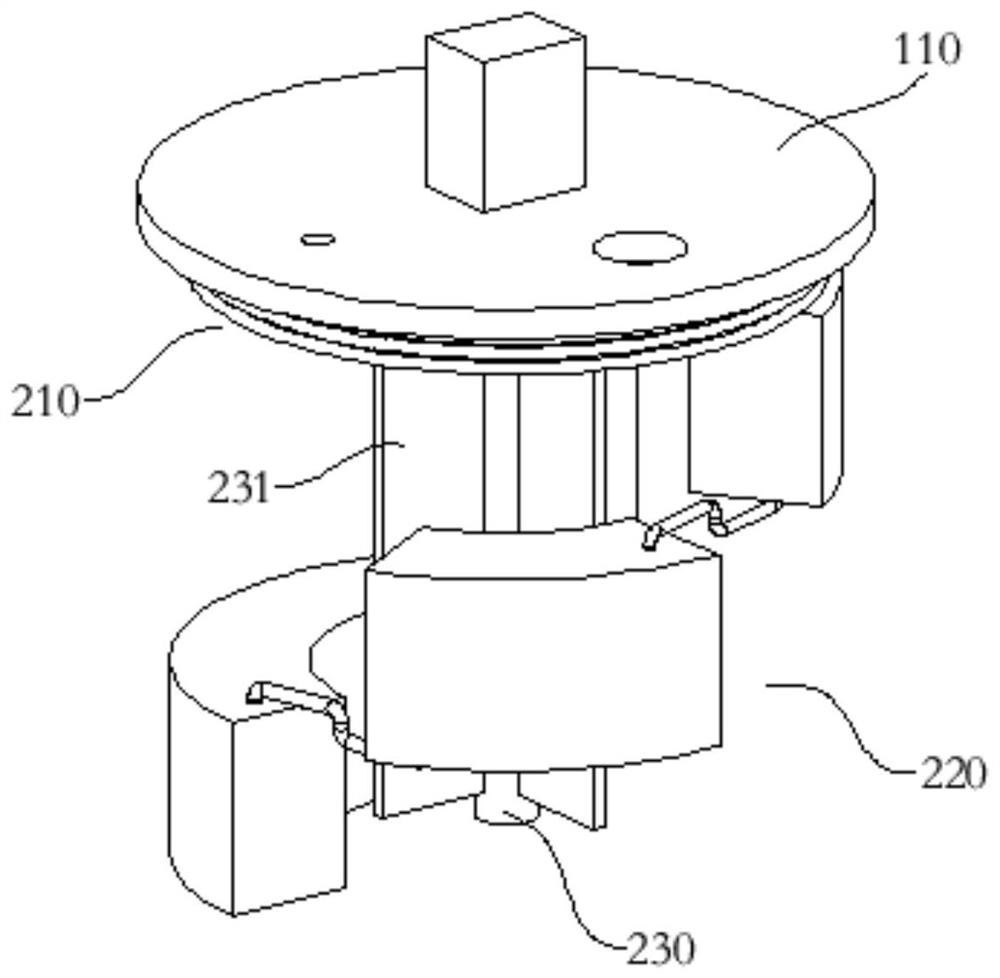

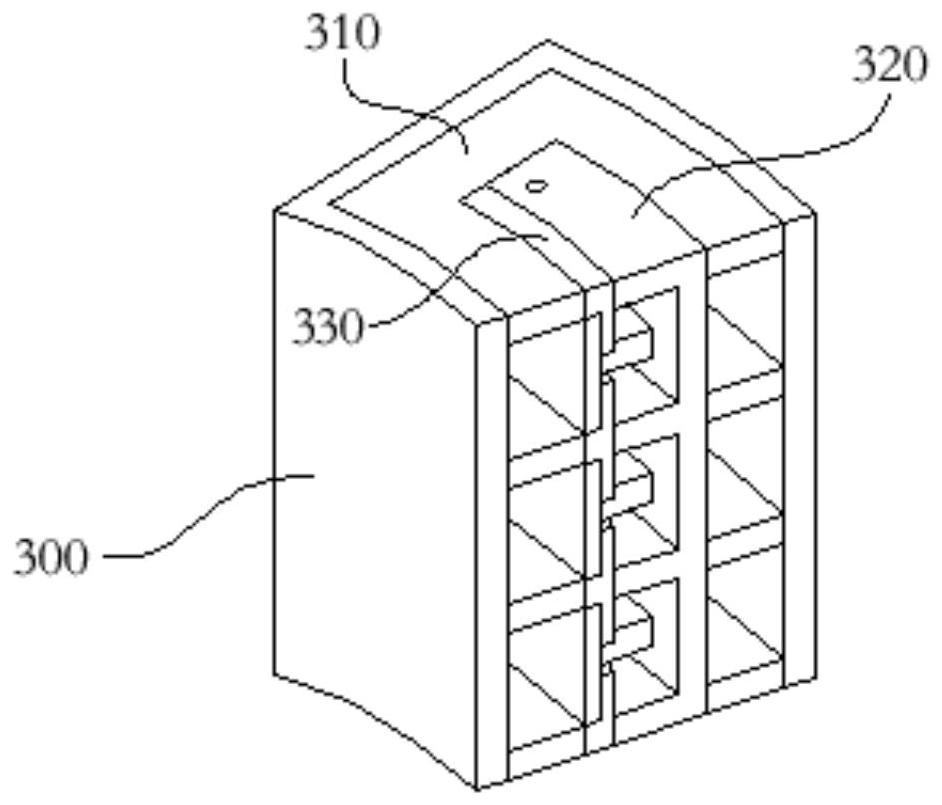

[0039] Such as Figure 1~2 As shown, this embodiment provides an environmentally friendly composite concrete water reducer preparation device, which includes a reactor, the reactor has a reactor main body 100, and a reaction chamber with an upward opening is provided at the reactor main body 100; the opening of the reaction chamber A cover plate 110 is provided, and a stirring assembly for extending into the reaction chamber is arranged at the cover plate 110; an auxiliary material feeding mechanism is arranged at the inner wall of the reaction chamber, and the auxiliary material feeding mechanism includes first heat exchange mechanisms 210 and 3 connected in sequence through pipelines. A second heat exchange mechanism 220; the first heat exchange mechanism 210 is located above the reaction liquid level, the three second heat exchange mechanisms 220 are located below the reaction liquid level, and the three second heat exchange mechanisms 220 are located in the reaction chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com