Tool for removing burrs at bottom of spline groove

A spline groove and burr technology, which is applied in the field of deburring tooling at the bottom of the spline groove, can solve problems such as high labor intensity, sore wrists, and low efficiency, and achieve the effects of improving efficiency, reducing labor intensity, and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The design concept, features and technical effects of the invention will be described in detail and completely below in conjunction with the accompanying drawings and preferred embodiments. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention. Based on the embodiments described in the present invention, other embodiments obtained by those skilled in the related art without creative work all belong to the protection scope of the present invention.

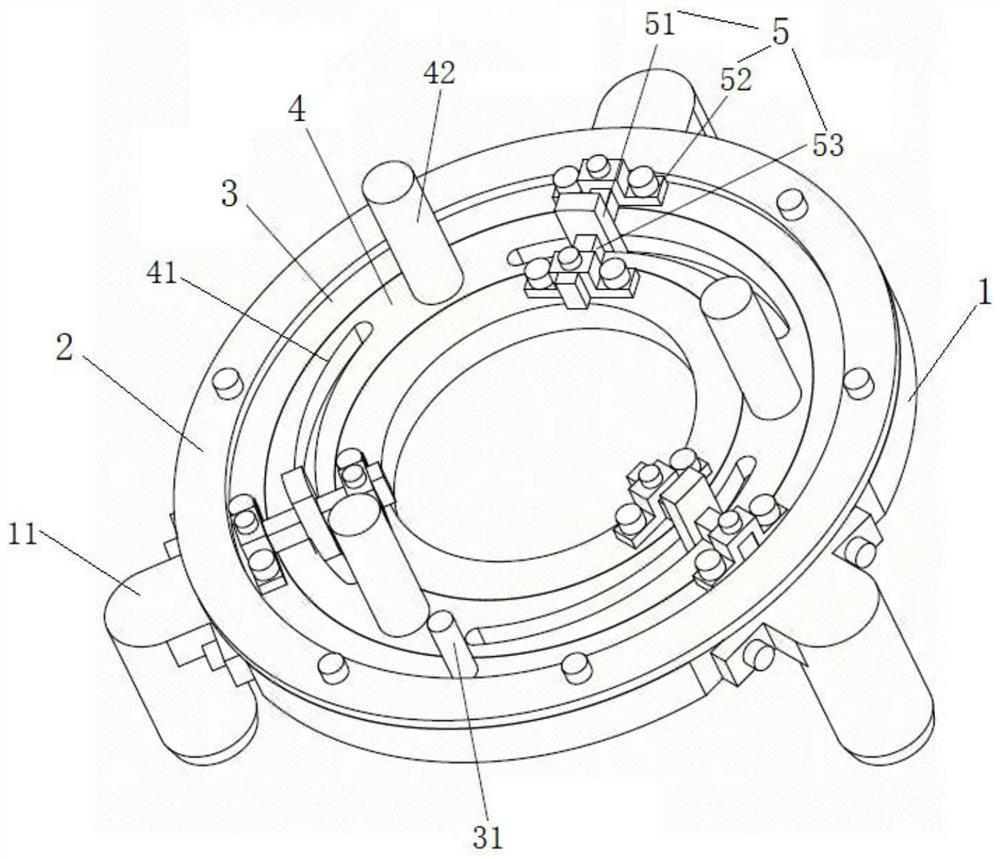

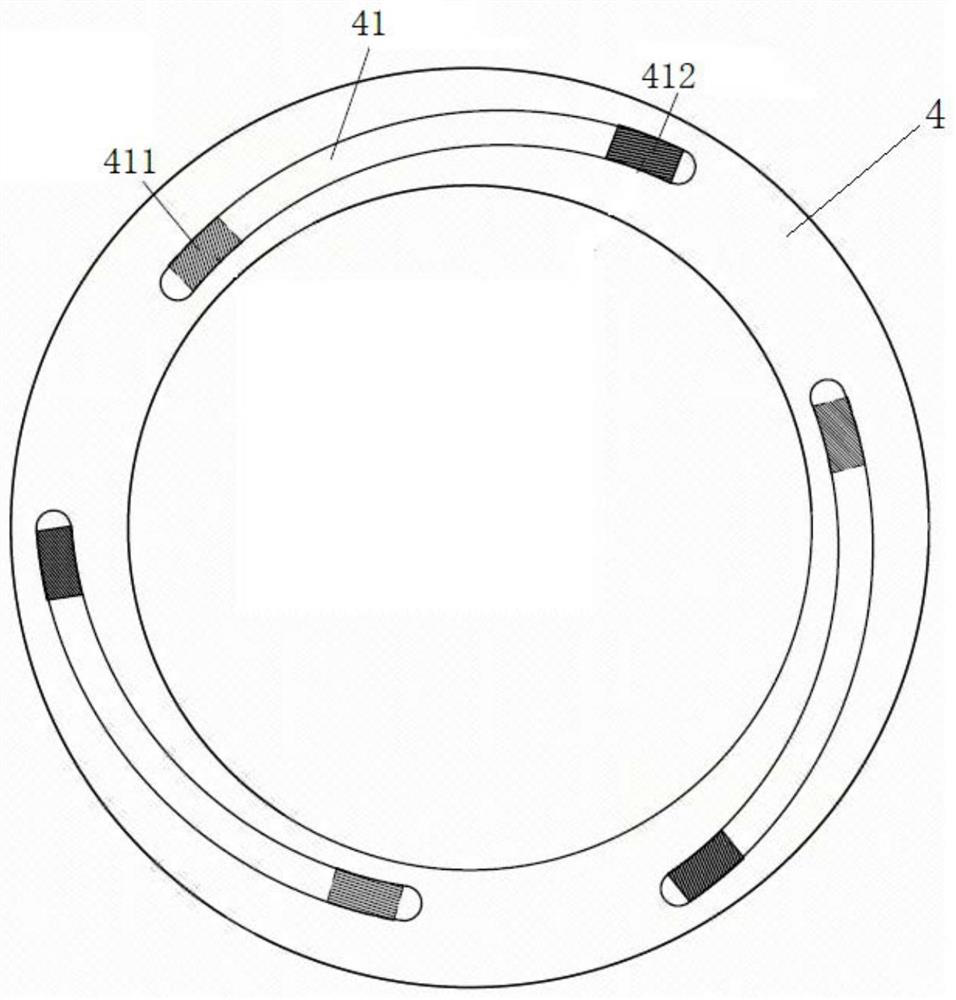

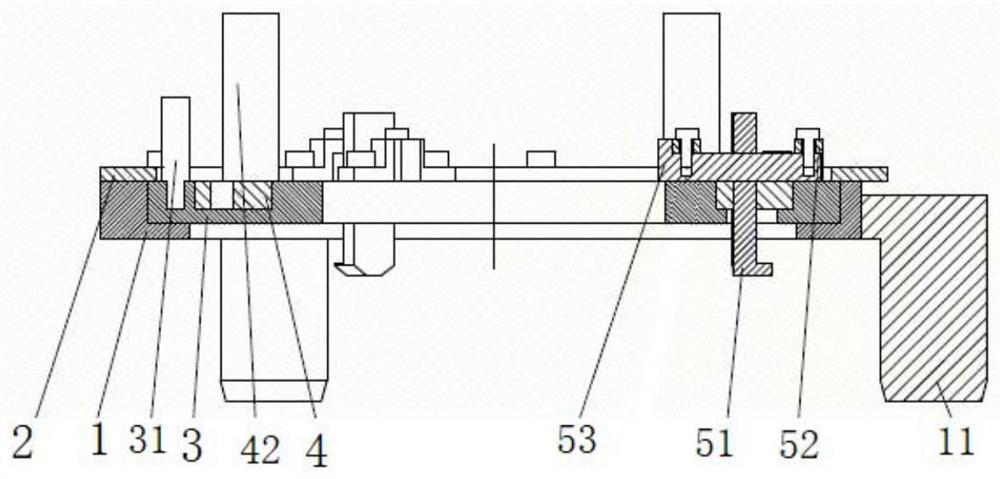

[0031] combine Figure 1-3 , the spline groove bottom deburring tooling designed this time belongs to the category of manual deburring methods, but compared with conventional manual deburring, it makes full use of the advanced nature of the mechanical structure, which not only avoids scratches on adjacent surfaces, It also greatly reduces the labor intensity of the operator, and at the same time greatly improves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com