Optomechatronic integrated operation clamp device

A technology for operating clips and opto-mechanical devices, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve problems such as equipment smashing, objects falling, and fixtures that cannot be clamped easily, and achieve automatic control, automatic control, The effect of ensuring the safety of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

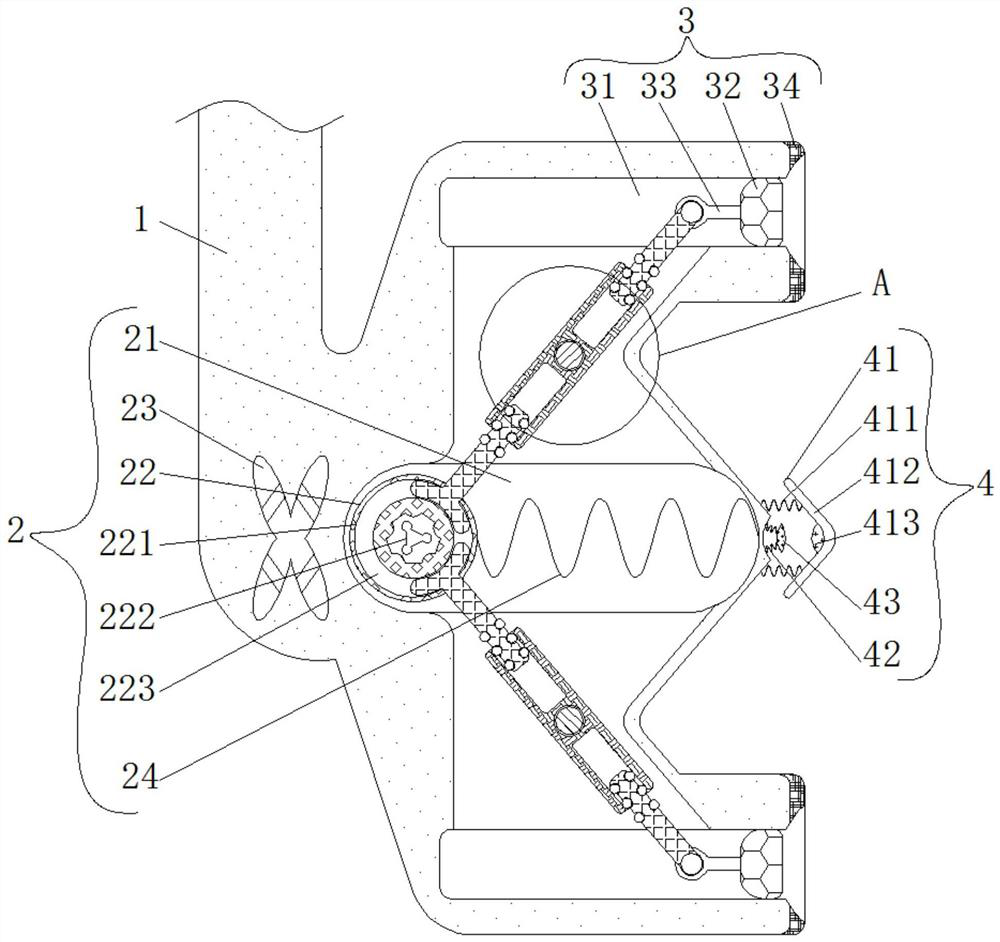

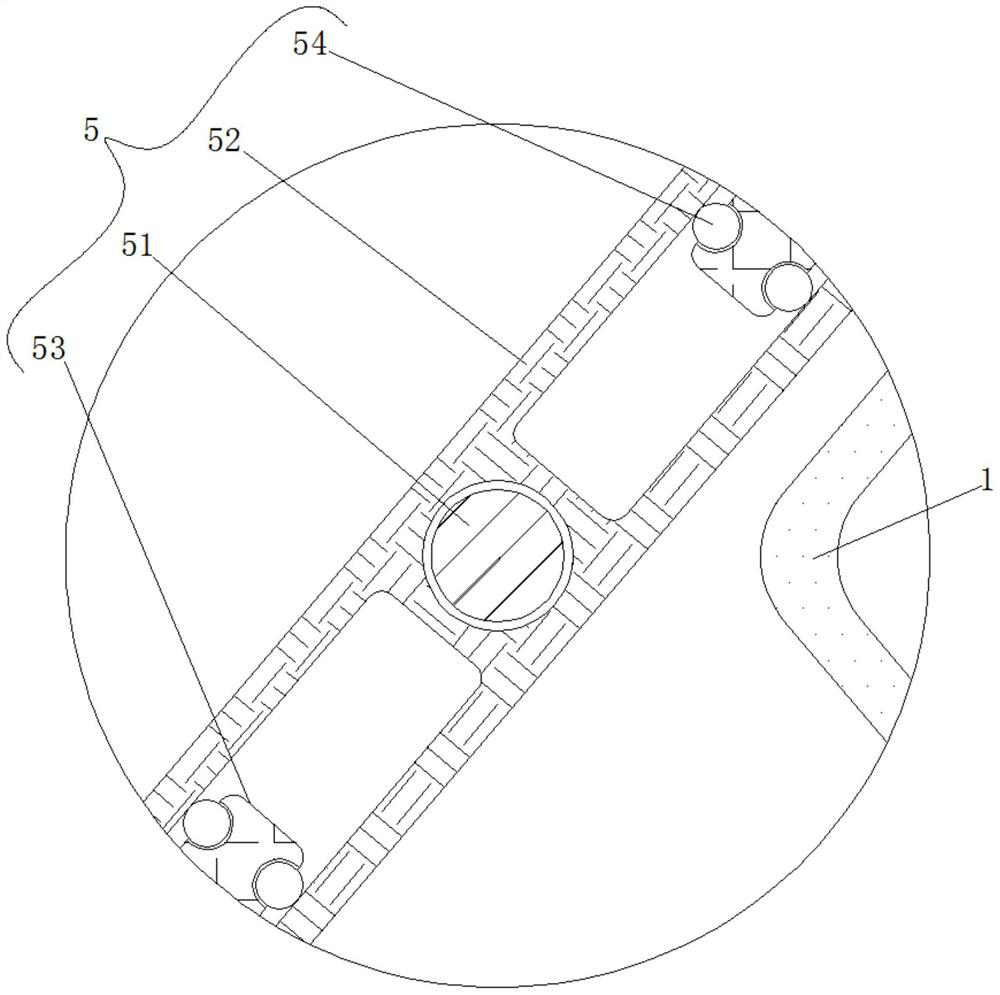

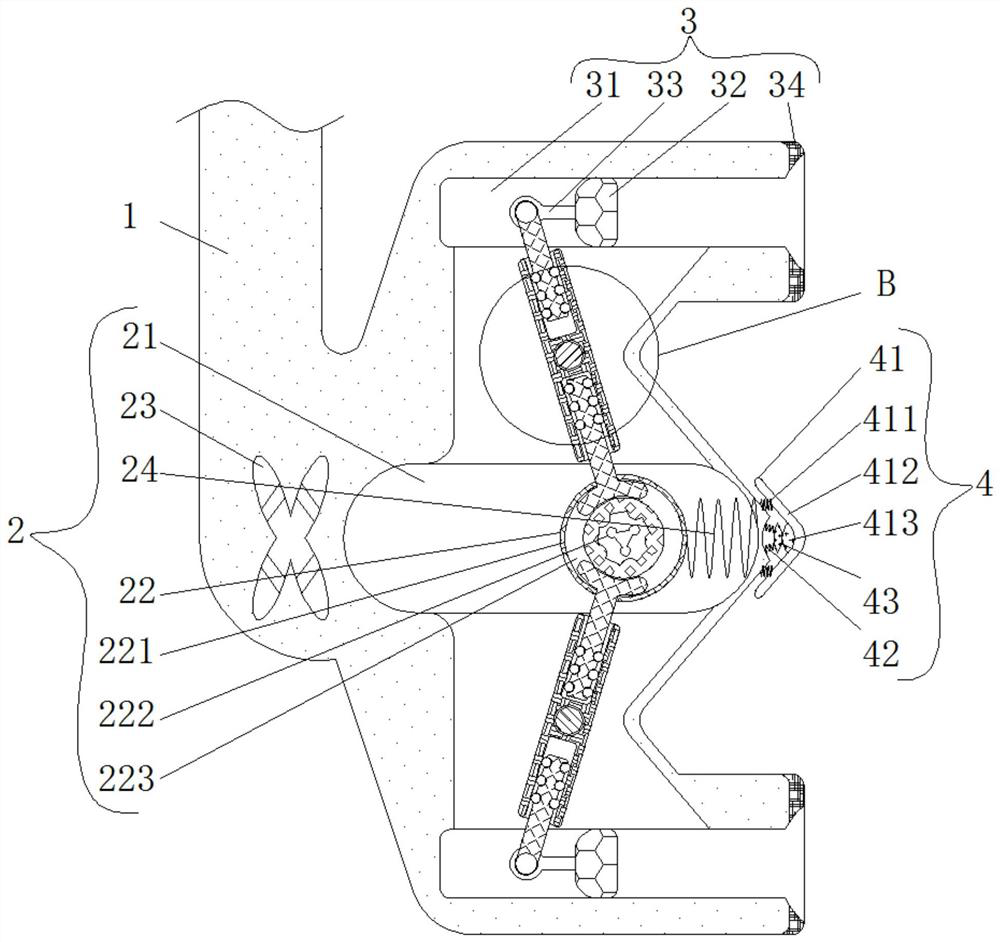

[0026] see figure 1 with image 3 , an optical-mechanical-electrical-integrated operating fixture device, including a clamping member 1, a transmission mechanism 2, an air pumping mechanism 3, a trigger mechanism 4, and a rotating mechanism 5, and the transmission mechanism 2 is elastically connected to the inside of the clamping member 1 and used to push The rotating mechanism 5 rotates and works, and the transmission mechanism 2 includes a movable groove 21, a stopper 22, an electromagnet 23 and a spring 24. The movable groove 21 is opened inside the clamping part 1, and the inside of the movable groove 21 is movably connected with a limiter 22. , the limiter 22 includes a moving part 221, a magnetic block 222 and an annular groove 223, the right side of the moving part 221 is fixedly connected with the spring one 24, the shape of the moving part 221 is a sphere and the material of the moving part 221 is a hard high-strength material , the moving part 221 plays the role of ...

Embodiment 2

[0029] see Figure 1-4 , an optical-mechanical-electrical-integrated operating fixture device, including a clamping member 1, a transmission mechanism 2, an air pumping mechanism 3, a trigger mechanism 4, and a rotating mechanism 5. The transmission mechanism 2 is elastically connected to the inside of the clamping member 1 and is used to push The rotating mechanism 5 rotates and works, and the transmission mechanism 2 includes a movable groove 21, a stopper 22, an electromagnet 23 and a spring 24. The movable groove 21 is opened inside the clamping part 1, and the inside of the movable groove 21 is movably connected with a limiter 22. , the limiter 22 includes a moving part 221, a magnetic block 222 and an annular groove 223, the right side of the moving part 221 is fixedly connected with the spring one 24, the shape of the moving part 221 is a sphere and the material of the moving part 221 is a hard high-strength material , the moving part 221 plays the role of fixation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com