Cam-assisted flexible continuum robot unit and robot

A robot and continuum technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that affect the robot's operation accuracy, it is difficult to bear torsional load and pressure load, and it is easy to bend, so as to achieve simple structure, improve precision and load The effect of ability and easy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

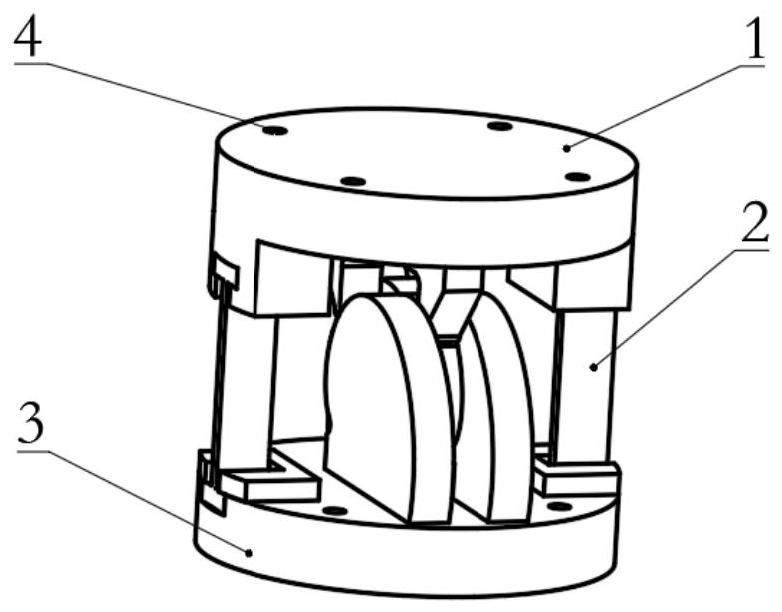

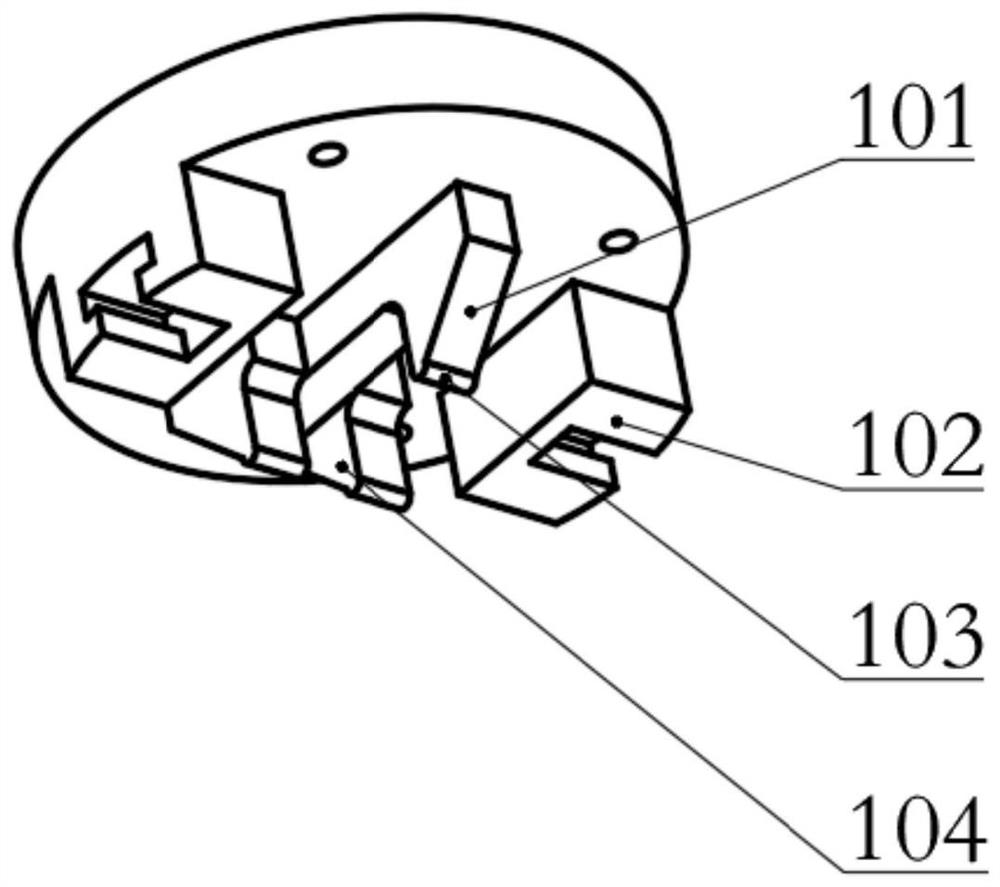

[0035] A cam-assisted flexible continuum robot includes an upper unit block 1 with a sliding fulcrum, a flexible structure 2, and a lower unit block 3 with cam-type contact assistance. The middle part of the flexible structure 2 has a rectangular cross-section. The unit blocks are installed and fixed through the interference fit between the two ends of the flexible structure 2 and the side grooves 102 of the upper unit block and the side grooves 302 of the lower unit block. Between two adjacent upper and lower unit blocks, the sliding fulcrum 101 and the cam-shaped contact assistant 301 are used to realize the high-cam motion of the continuum robot unit. The two adjacent unit blocks are sequentially arranged staggered by 90° along the axis direction of the overall continuum robot, and a plurality of driving wires pass through the threading through holes 4 in sequence. formed from this Figure 5 As shown, the overall continuum robot includes 9 continuum units.

[0036] The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com