Loop heat pipe with multiple heat absorption and release components

A heat-absorbing component and loop heat pipe technology, applied in the field of loop heat pipes, can solve the problems of difficulty in dissipating heat from different heat sources, inability to achieve multi-heat source transfer, etc., and achieve the effects of improving temperature distribution uniformity, cost saving, and capillary force enhancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

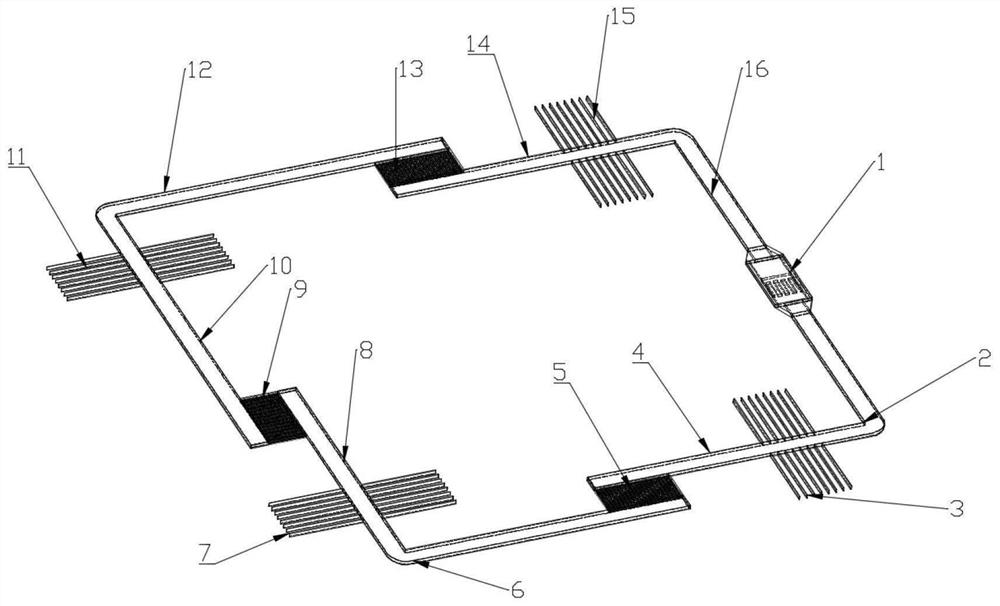

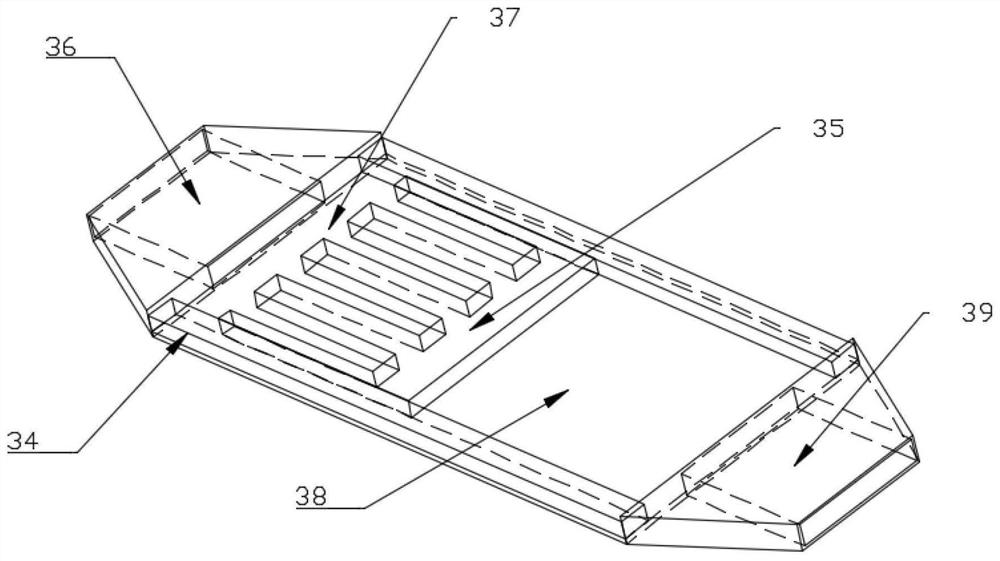

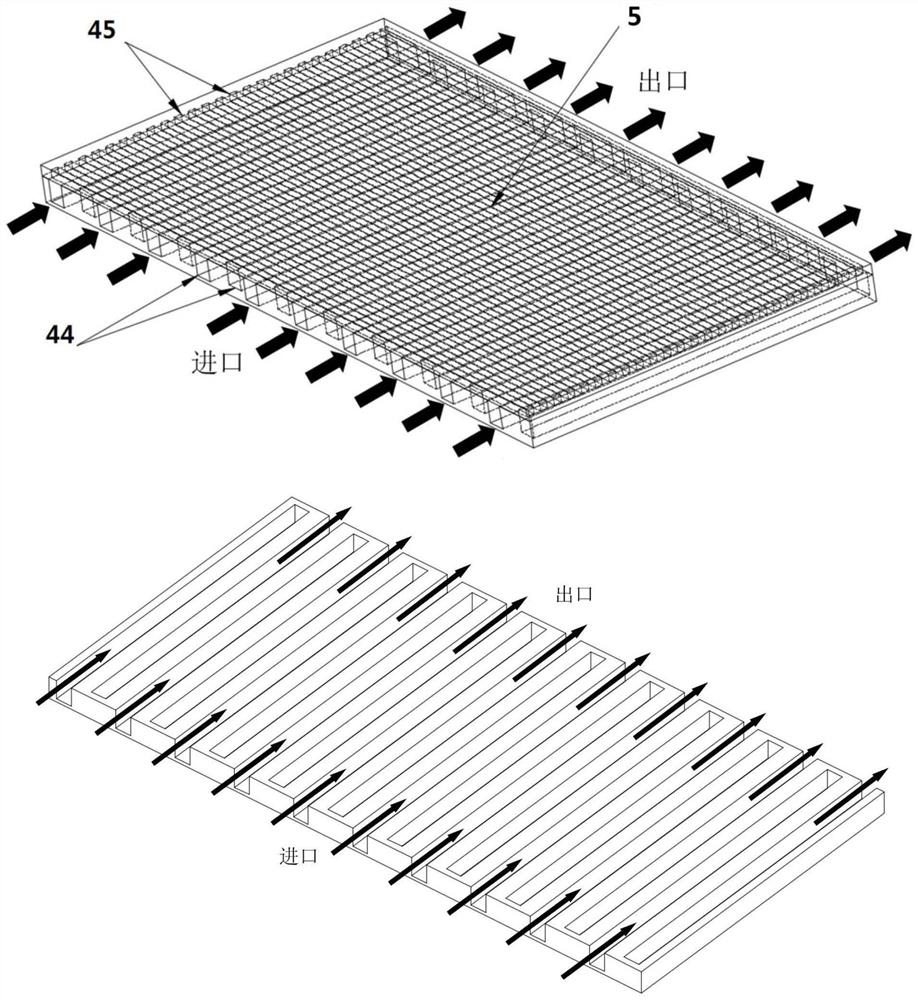

[0043] figure 1 , 4 , 5 discloses a loop heat pipe with multiple heat-absorbing components and multiple heat-releasing components. Such as figure 1 As shown, a loop heat pipe includes multiple heat absorbing components, such as 1, 5, 9, 13. Multiple heat release components, eg 3, 7, 11, 15. The plurality of heat-absorbing components and the plurality of heat-dissipating components are connected through fluid pipelines, such as 2, 4, 8, 12, 14, 16. Heat absorbing parts and / or heat releasing parts are 3 or more, such as figure 1 There are four heat-absorbing parts and four heat-radiating parts respectively. At least one heat radiation component is matched with the fluid pipeline downstream of the at least one heat absorption component, and the at least one heat absorption component absorbs the heat of the heat source, and the fluid pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com