Open flat plate phase change heat storage tank

A technology of phase change heat storage and heat storage tank, which is applied in the direction of heat storage equipment, indirect heat exchangers, heat exchanger types, etc. Material and other issues, to achieve the effect of stable temperature, convenient equipment installation and site requirements, and wide system adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

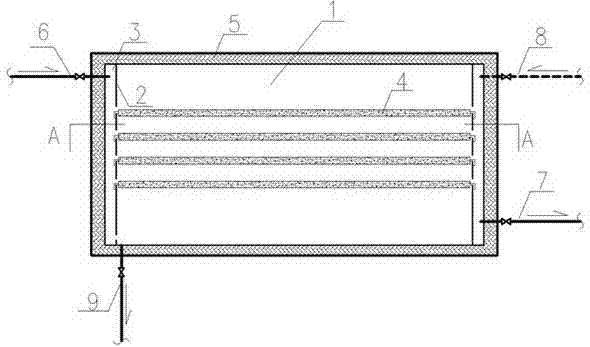

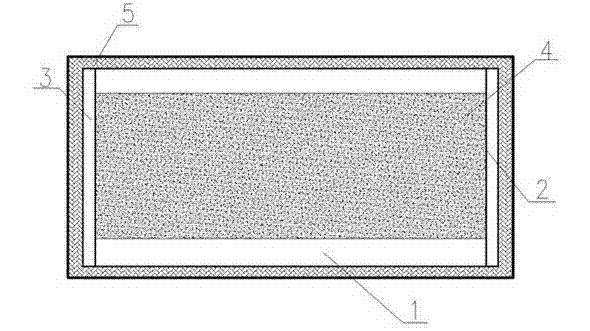

[0022] Embodiment 1: as figure 1 As shown, in the open flat plate phase change heat storage tank, two detachable groove plates 2 are installed in the heat storage tank 1, and a diversion groove 3 is formed between the wall surfaces on both sides of the heat storage tank 1 and the groove plates 2 , the diversion groove 3 is connected with the inside of the hot water storage tank, the phase change heat storage plate 4 is fixed on the card groove plate 2, the heat storage tank 1 is provided with an insulation layer 5, and the hot water storage tank 1 is respectively connected with high temperature hot water injection Water pipe 6, hot water supply pipe 7, water return pipe 8, drain pipe 9, each water pipe is all equipped with a valve to regulate the flow.

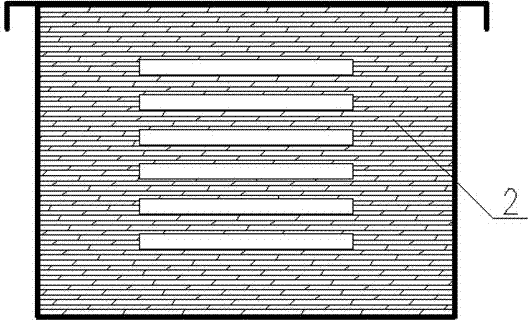

[0023] Such as figure 1 and figure 2 As shown, the phase change heat storage plate 4 is a rectangular flat box, the two sides of the flat box are fixed in the hot water storage tank 1 through the slots, and the phase change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com