Integrated foam performance detection box and detection method

A detection box and integrated technology, applied in the integrated foam performance detection box and the detection field, can solve the problems of missing 25% of the liquid elution time, large error in test data, and many device components, etc., to reduce the use of space and equipment quality. , to ensure the level of the measuring device and the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

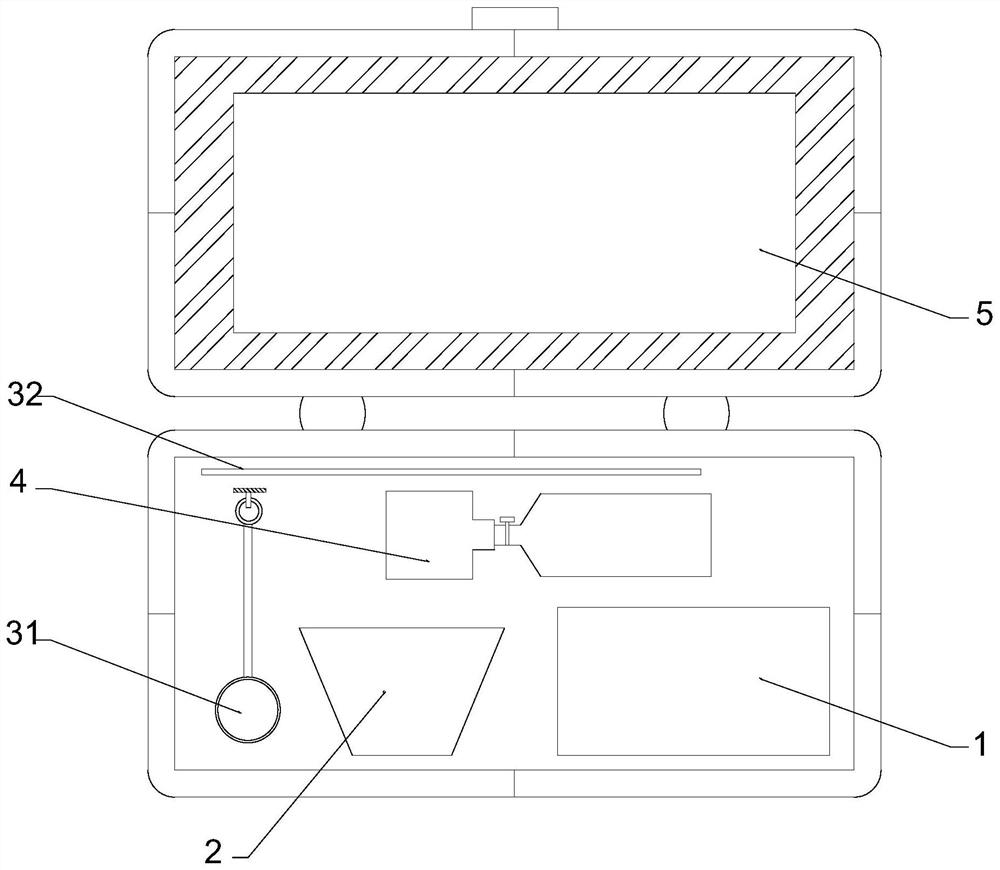

[0034] Such as figure 1 As shown, an integrated foam performance detection box proposed by the present invention includes a measuring device 1, a foam collector 4, a foam baffle 2 and a support frame arranged in a detection box body 5, and the support frame includes a support rod 32 And the support ring 31, the overall mass of the detection box of the present invention is no more than 10kg.

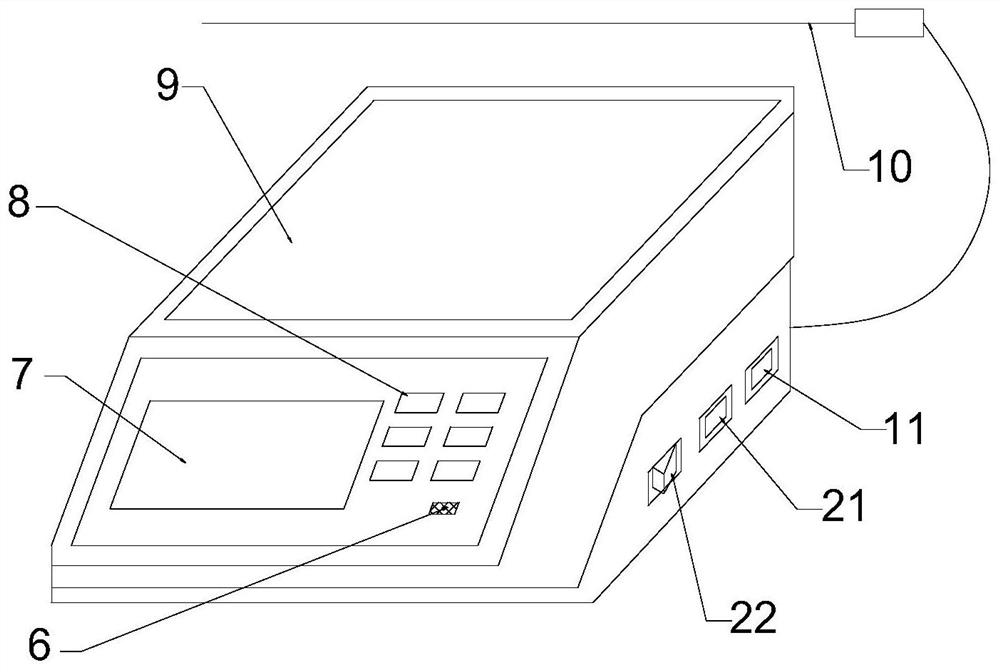

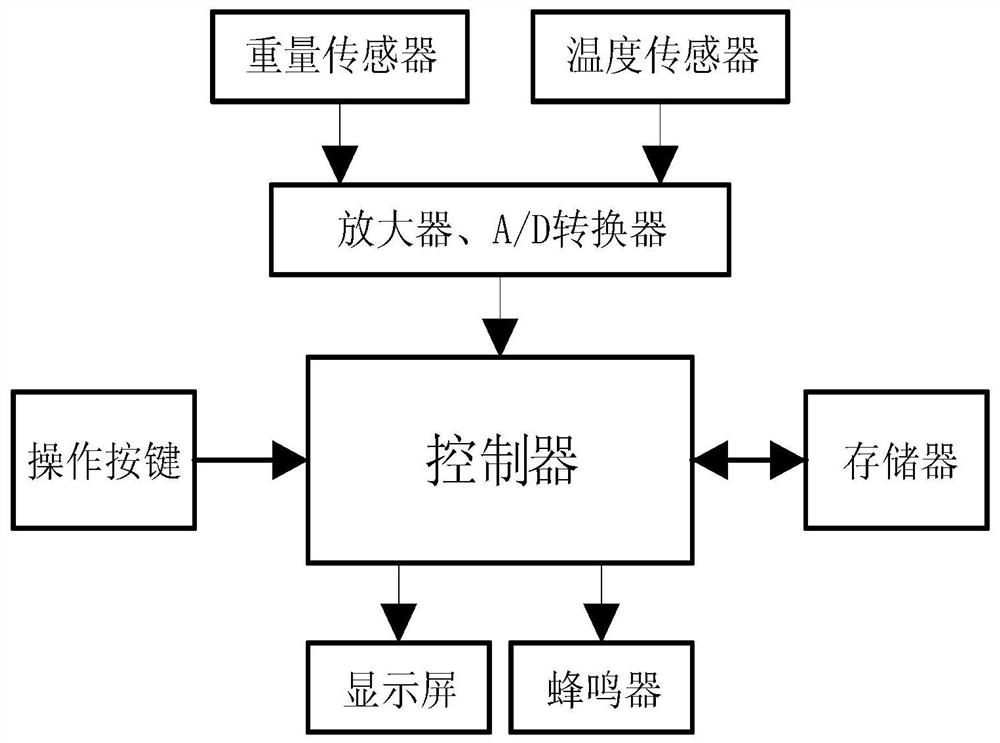

[0035] Such as figure 2 with image 3As shown, the measuring device 1 includes a temperature sensor, a controller and a rechargeable battery arranged in the casing, the top of the casing is an electronic balance 9, and the front panel of the casing is provided with a buzzer 6, a display Screen 7 and operation panel 8, the side panel of described housing is provided with power key 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com