Rod-shaped material accumulation angle side wall collapse test device and method

A material accumulation and test device technology, applied to measuring devices, analytical materials, instruments, etc., can solve problems such as time-consuming, labor-intensive, high cost, and differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

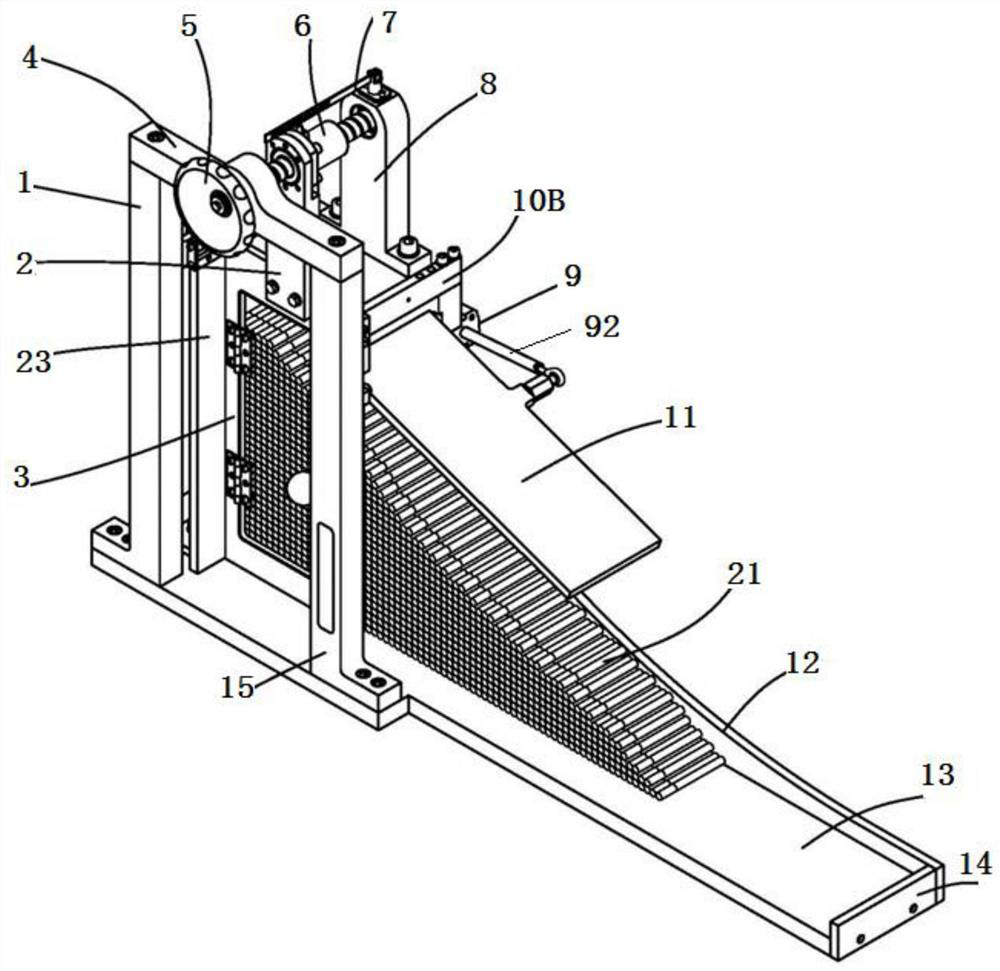

[0083] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the rod-shaped material accumulation angle side wall collapse test device comprises a left wall panel 23, a front wall panel 24, a rear wall panel 3, a right door panel 11, a bottom panel 13, a left support column 1, a right support column 15, a rear support seat 4, Front support seat 8, driving mechanism 6 and cylinder 9;

[0084] The left wallboard 23 is fixedly installed on the left side of the bottom plate 13;

[0085] The front wall panel 24 is fixedly installed on the front side of the base plate 13;

[0086] The left support column 1 and the right support column 15 are fixedly installed on the rear side of the base plate 13;

[0087] The left wallboard 23 is on the right side of the left support column 1, and the right support column 15 is on the right side of the left wallboard 23;

[0088] The rear support base 4 is fixedly installed on the top of the left support column 1 and the right support...

Embodiment 2

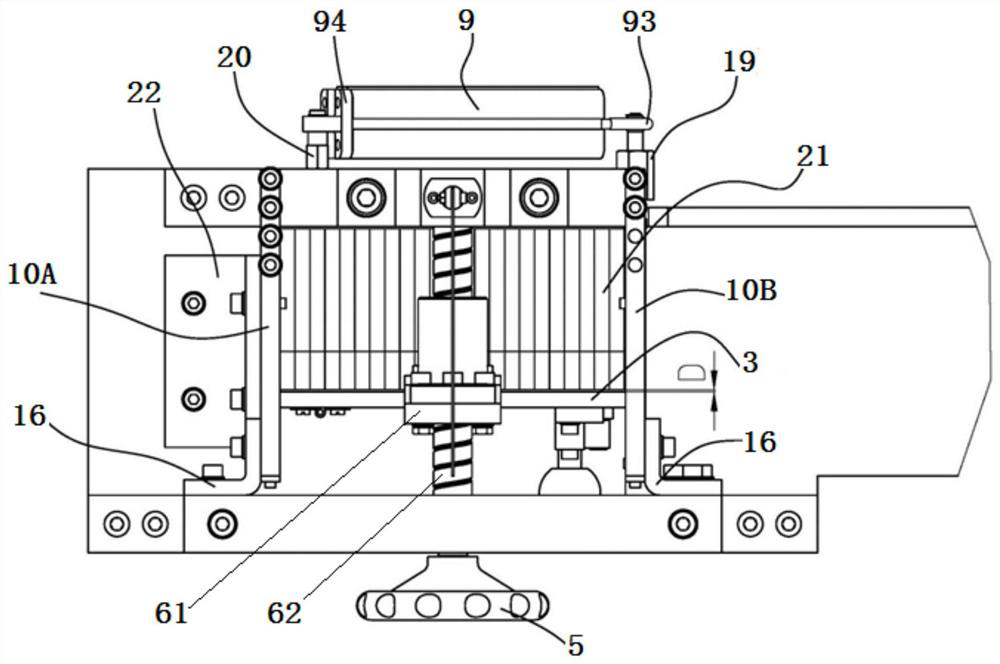

[0098] Based on the rod-shaped material accumulation angle side wall collapse test device of embodiment one, such as Figure 9 As shown, the driving mechanism 6 is a ball screw structure, its ball nut 61 is connected with the cantilever 2, and the two ends of its ball screw 62 are respectively connected with the rear support seat 4 and the front support seat 8 through bearings;

[0099] The rear wall panel 3 is fixedly connected to the lower end of the cantilever 2 .

[0100] better, such as Figure 5 As shown, a scale mounting seat 17 is installed on the rear support seat 8;

[0101] The ruler mounting base 17 is used for installing the front and rear direction ruler 7 .

[0102] Preferably, a pointer 18 is installed on the ball nut 61 , the top of the pointer 18 is flush with the lower end of the scale 7 , and is used to indicate the distance between the rear wall panel 3 and the front wall panel 24 .

[0103] Preferably, a hand wheel 5 is installed at one end of the ball...

Embodiment 3

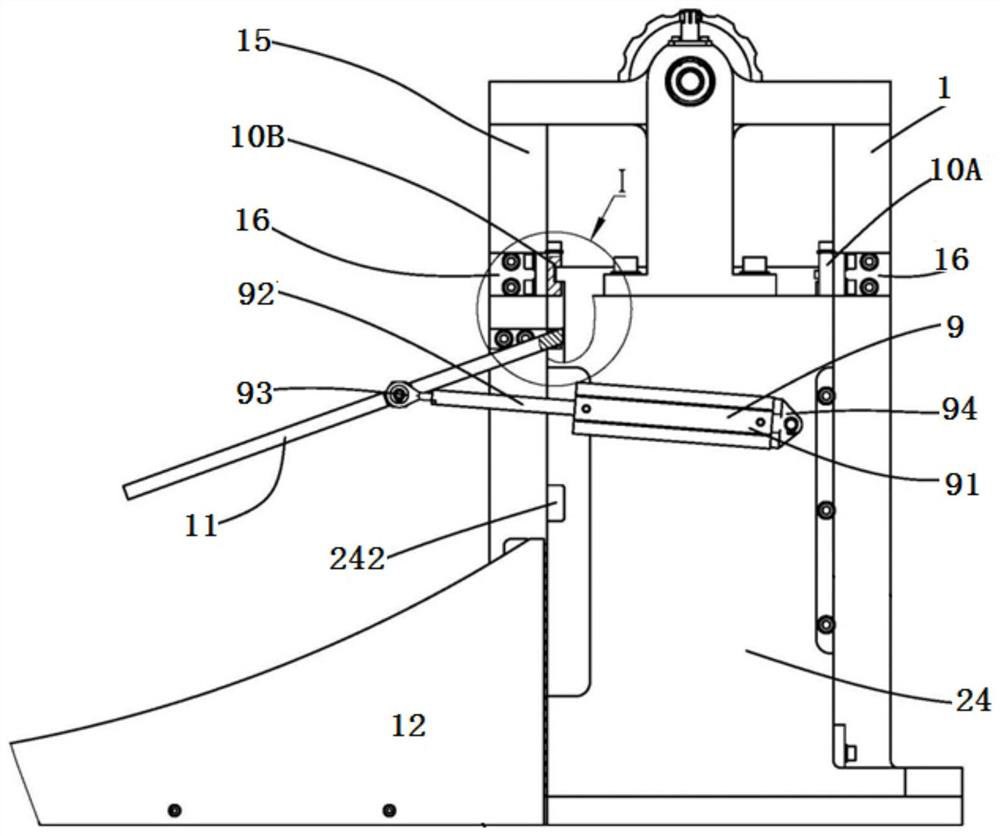

[0110] Based on the rod-shaped material accumulation angle side wall collapse test device of embodiment one, such as Figure 7 As shown, the rear wall panel 3 has a window for installing a transparent door 36 in the middle, and an iron block 34 is installed in the middle of the right side;

[0111] The left end of the transparent door 36 is connected to the rear wall panel 3 through a hinge 31 and can be pulled back;

[0112] A vertical connection bar 32 is installed at the right end of the transparent door 36;

[0113] A handle 33 is installed on the connecting bar 32;

[0114] A permanent magnet 35 is installed on the handle 33, and a transparent door 36 can be opened by holding the handle 33 and pulling it backward;

[0115] When the transparent door 36 was closed, the permanent magnet 35 attracted the iron block 34 installed in the corresponding position of the back wall panel 3, thereby locking the transparent door 36 and would not be disengaged.

[0116] Preferably, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com