Metal plate panel bending tool and bending method

A sheet metal panel and tooling technology, applied in the field of sheet metal processing, can solve problems such as hole deformation, achieve the effect of improving utilization, not easy to bend and deform, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

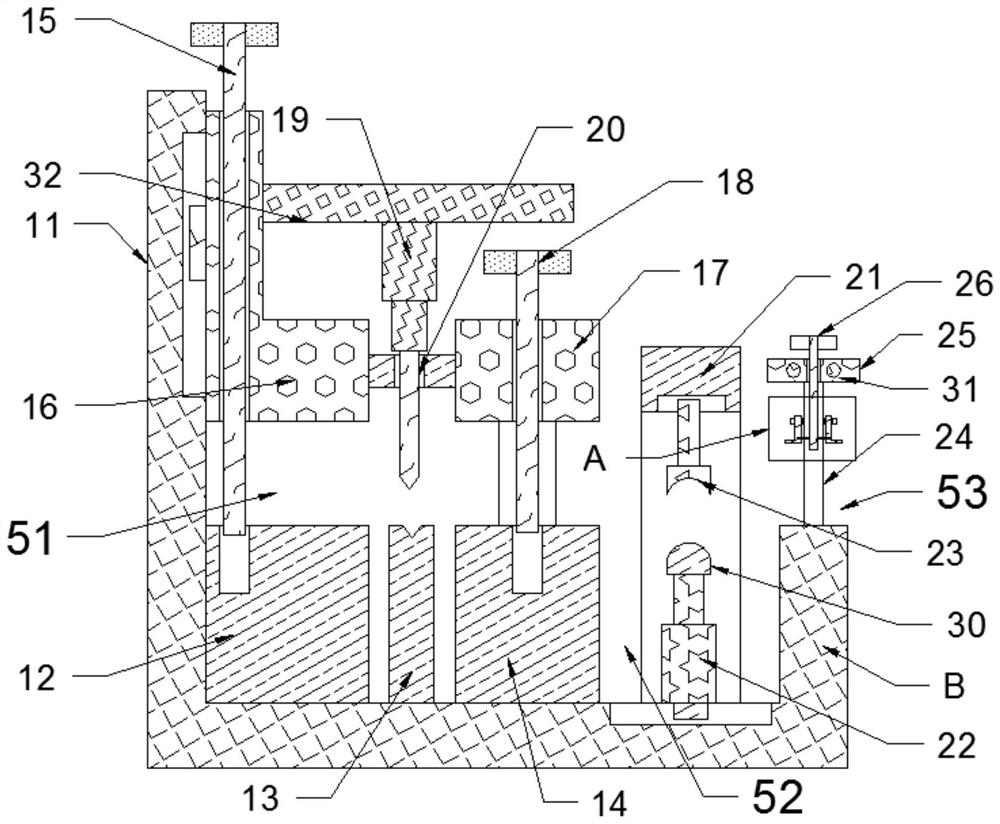

[0018] combined with Figure 1-3 The sheet metal panel bending tooling and bending method include a crimping mechanism 51, which is characterized in that: the crimping mechanism 51 is used for crimping on the workpiece bending line;

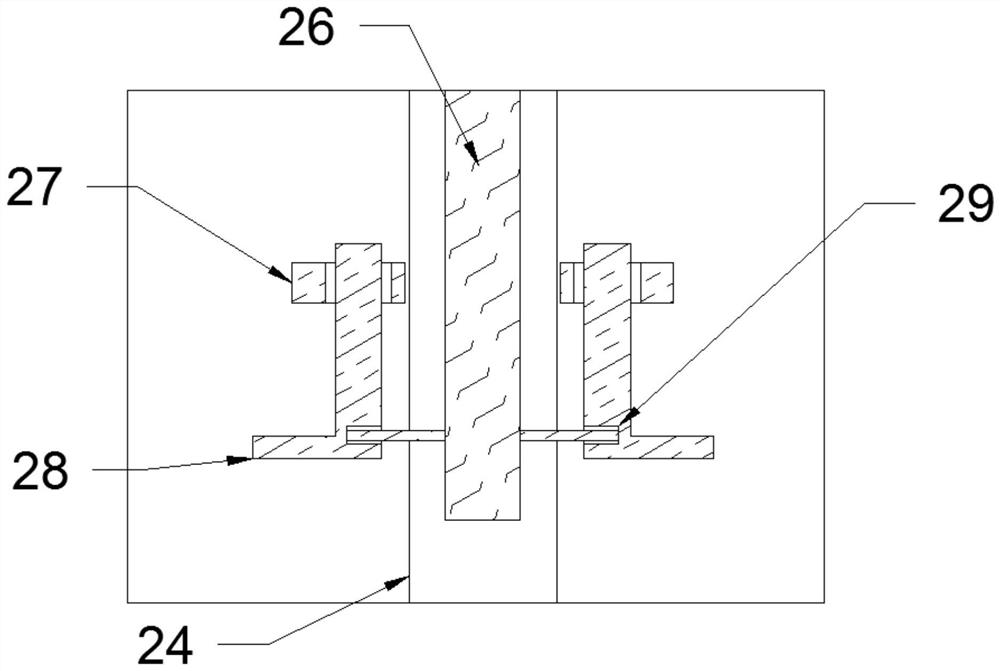

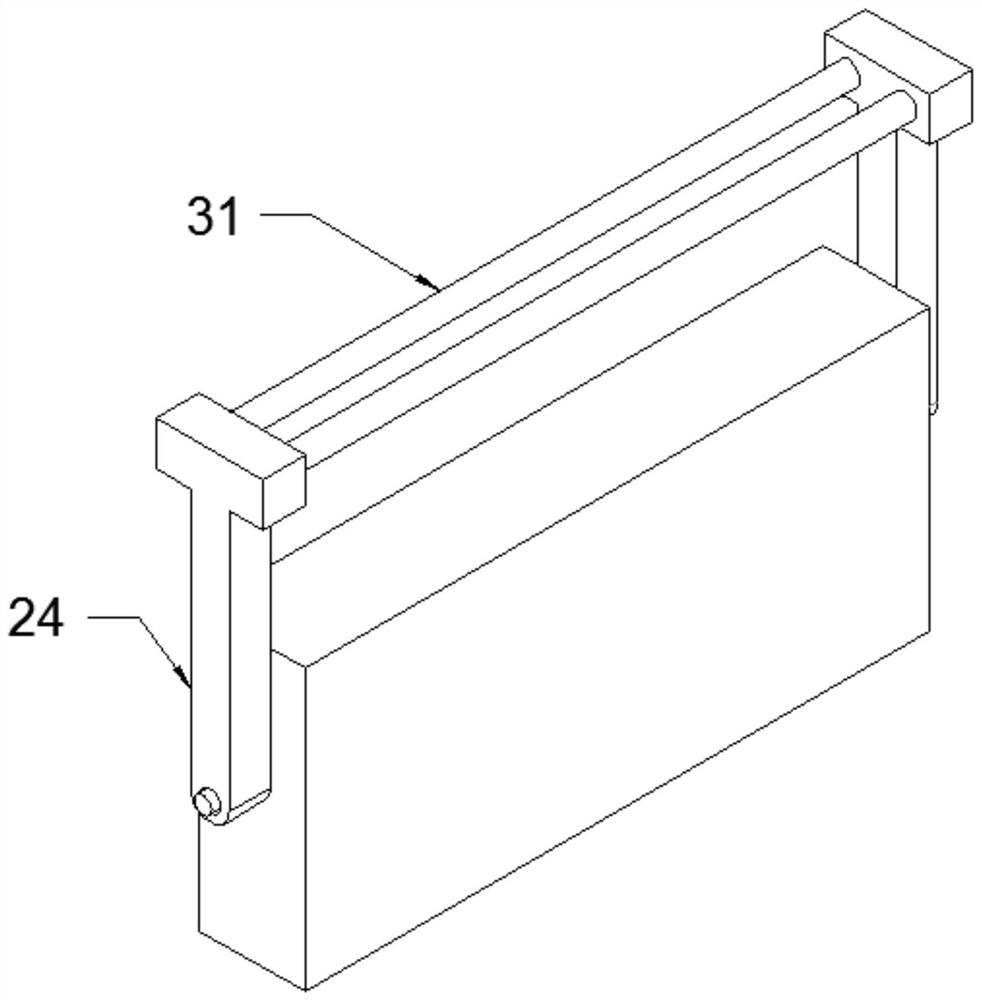

[0019] One side of the crimping mechanism 51 is provided with a clamping mechanism 53, and the clamping mechanism 53 includes a straight rod 24, and two sliding shafts 31 are fixedly arranged on one side of the straight rod 24, and three slide shafts 31 slide on the sliding shaft 31. A suspension block 25, each side of the suspension block 25 is threadedly engaged with a clamping screw 26, one side of the clamping screw 26 is fixedly connected with three steel wire ropes 29, and the other side of each steel wire rope 29 is fixedly connected On the clamping jaw 28, one end of the clamping jaw 28 is threadedly engaged with a splint 27, and the hole of the workpiece to be processed is passed through the clamping jaw 28 and locked, and at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com