Production process and equipment for touring car roof elliptical mirror

A technology for production equipment and elliptical mirrors, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc. It can solve the problems of unsatisfactory polishing effect and the inability to control the supply of polishing liquid according to actual conditions, so as to improve the use of Effects of life, wear reduction, and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

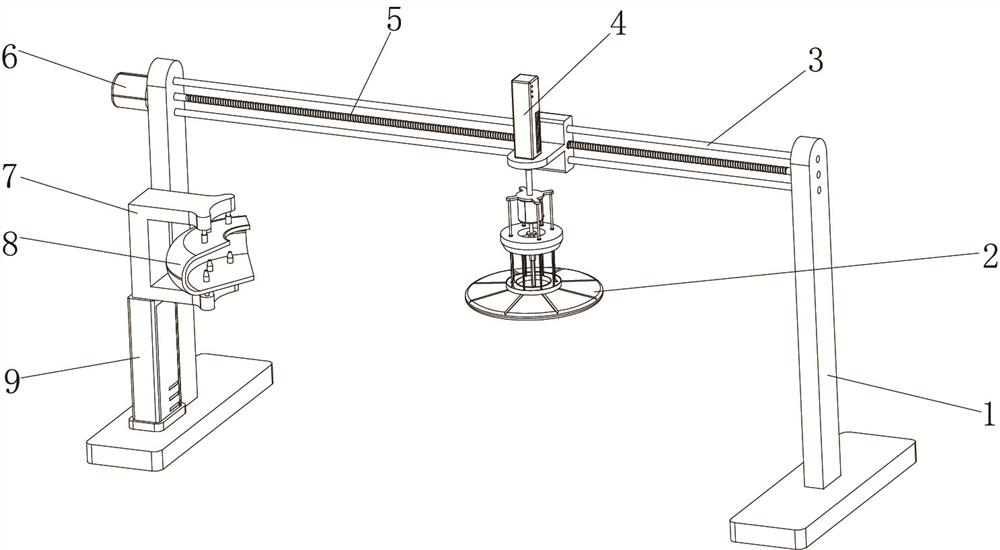

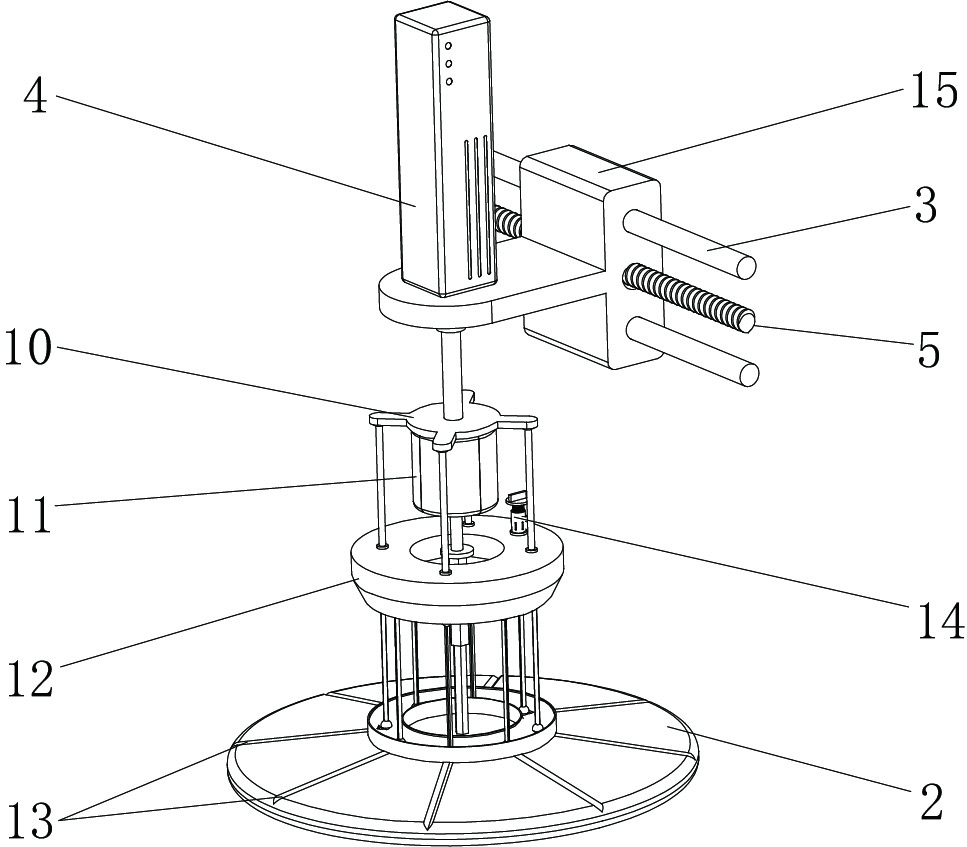

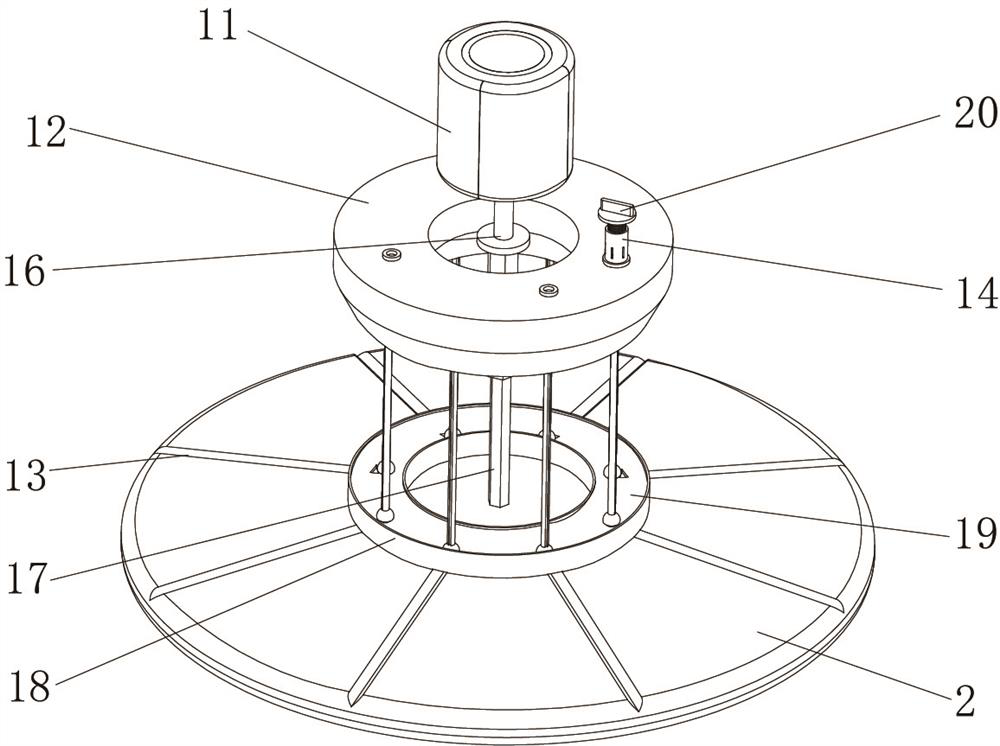

[0047] Embodiment 1: A kind of RV ceiling oval mirror production equipment, such as Figure 1-8 As shown, it includes a support frame 1, a polishing mechanism and a translation mechanism that controls the translation of the polishing mechanism. The polishing mechanism includes an electric telescopic cylinder 4, a polishing motor 11 and a polishing disc 2. The output end of the electric telescopic cylinder 4 is fixed with a lifting frame by screws 10. The polishing motor 11 is fixed on the bottom outer wall of the lifting frame 10 by bolts. The output end of the polishing motor 11 is rotatably connected with a rotating main shaft 16, and the outer wall of the bottom end of the rotating main shaft 16 is fixed with a rotating sleeve 22 by bolts. The rotating sleeve The inner wall of the bottom end of 22 is slidingly connected with a rotating rod 17, and the same spring 21 is installed between the top of the rotating rod 17 and the inner wall of the top of the rotating sleeve 22. ...

Embodiment 2

[0055] Embodiment 2: A kind of RV roof oval mirror production equipment, such as figure 1 , Figure 8 As shown, in order to facilitate cleaning after polishing; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of one side of the support frame 1 is fixed with a cleaning box 9 by bolts, and the top of the cleaning box 9 is equipped with a mounting frame 7, One side of the installation frame 7 is provided with an arc-shaped cover 8, the shape of the arc-shaped cover 8 is adapted to the polishing disc 2, and the upper and lower inner walls of the arc-shaped cover 8 are fixed with evenly distributed cleaning nozzles 33, and the cleaning nozzles 33 are installed on the installation frame 7 Above, cleaning liquid is filled in the cleaning box 9, and a pump body for pumping the cleaning liquid from the cleaning box 9 to the cleaning nozzle 33 is arranged in the installation frame 7; by setting arc-shaped cover 8, cleaning nozzle 33 and othe...

Embodiment 3

[0056] Embodiment 3: A kind of RV roof oval mirror production equipment, such as Figure 9 , Figure 10 As shown, in order to facilitate the replenishment of polishing liquid; this embodiment makes the following improvements on the basis of embodiment 1: the top of the annular liquid storage tank 12 is provided with a connecting seat 35, and the top of the connecting seat 35 is connected with a liquid supply pipe 37, One end of the liquid supply pipe 37 is connected with a polishing liquid supply system. The inner wall of the annular liquid storage tank 12 is fixed with a limit frame 40 by screws, and a mounting rod 42 is slidably connected to the limit frame 40. The bottom of the mounting rod 42 is equipped with a buoyancy Airbag 41, the top of the mounting rod 42 is fixed with a sealing plug 38, the top of the sealing plug 38 is adapted to the shape of the inner wall of the connecting seat 35; by setting the sealing plug 38, the buoyancy airbag 41 and other structures, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com