High-temperature processing device for film production

A high-temperature processing and thin-film technology, which is applied in applications, household appliances, and other household appliances, can solve the problems of film material adhesion and difficulty in cleaning, and achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

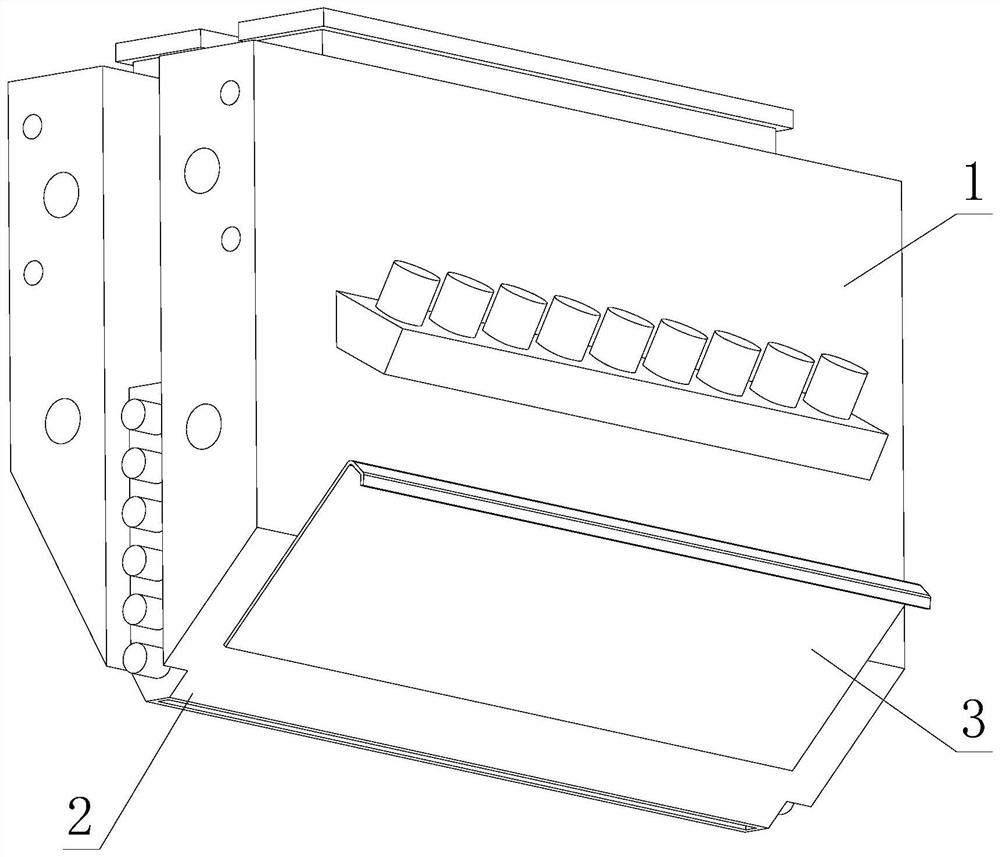

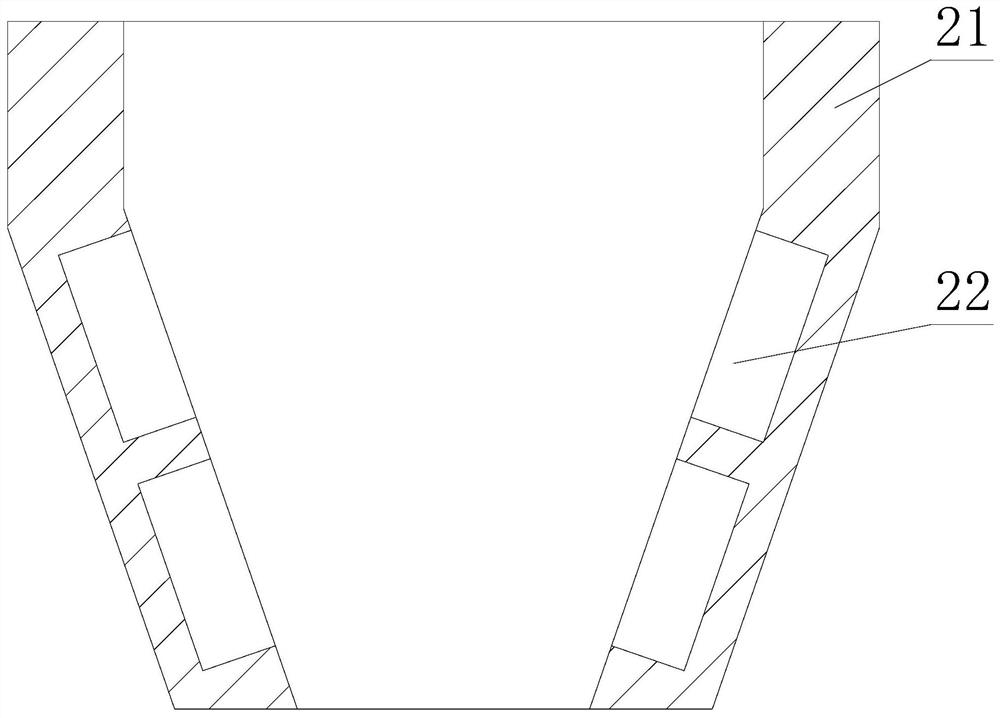

[0023] Such as figure 1 - image 3 As shown, the present invention provides a high-temperature processing device for film production, including a body 1, a nozzle 2 is arranged at the lower end of the body 1, a side plate 3 is arranged on one side of the lower end of the body 1, and a nozzle is arranged inside the nozzle 2 21 , both sides inside the nozzle 21 are fixedly connected with detachment structures 22 .

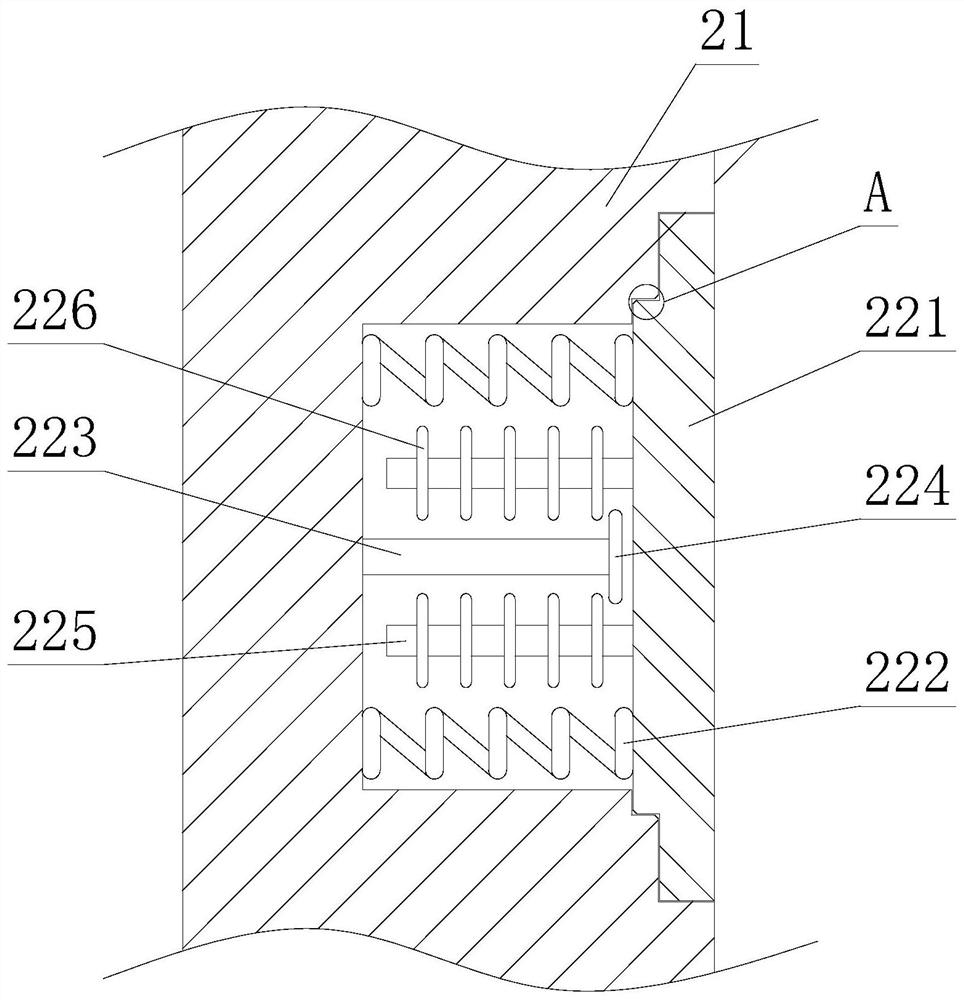

[0024] Wherein, the interior of the breakaway structure 22 is provided with a vibration plate 221, the side of the vibration plate 221 close to the nozzle 21 is fixedly connected with a vibration rod 225, the outer surface of the vibration rod 225 is fixedly connected with a vibration pick 226, and the nozzle 21 is close to the side of the vibration plate 221. One side is fixedly connected with a fixed rod 223 , and one end of the fixed rod 223 close to the vibration plate 221 is fixedly connected with a dial 224 , and a spring 222 is fixedly connected between the v...

Embodiment 2

[0027] Such as Figure 4-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the inside of the vibration plate 221 is provided with a detachment block 2211, and the inside of the detachment block 2211 is provided with an air cavity 2212, and the upper and lower ends of the air cavity 2212 are fixed. Connected with the connecting rod 2213 , the end of the air chamber 2212 away from the nozzle 21 is provided with a circular arc protrusion 2214 , and an inner air chamber 2215 is provided inside the circular arc protrusion 2214 .

[0028] Wherein, the vibrating plate 221 is designed in a convex shape, the edge of the narrower end of the vibrating plate 221 is provided with a chamfer, the edge where the nozzle 21 contacts with the corner of the vibrating plate 221 is provided with a chamfer, and the arc protrusion 2214 is half Circular design, the distance between every two arc protrusions 2214 is relatively large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com